Home / Product / Roller Bearings / Cylindrical Roller Bearings / Single Row Full Complement Cylindrical Roller Bearings

Single Row Full Complement Cylindrical Roller Bearings

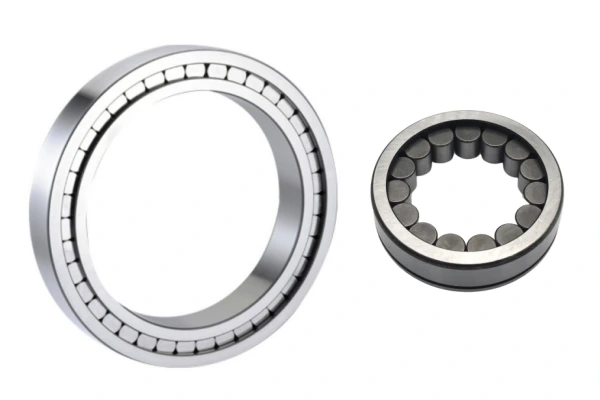

Single Row Full Complement Cylindrical Roller Bearings are designed to excel in demanding environments where traditional caged bearings might fall short. Their defining characteristic is the absence of a cage, allowing for a greater number of rolling elements. This full complement design directly translates to a substantially higher radial load carrying capacity, making them ideal for heavy industrial applications. These durable bearings are frequently chosen for their robust construction and ability to handle significant forces, ensuring reliable operation even under extreme conditions.

Loading...

Total 129 Results

Part Number

Bore Dia

Outer Dia

Width

Shoulder Dia Of Inner Ring

Shoulder Dia Outer Ring

Raceway Diameter Outer Ring

Dynamic Radial Load

Static Radial Load

Max Speed

Weight

NCF 29/560 V/HB1

560 mm

750 mm

112 mm

628 mm

682 mm

709 mm

681750 lbf

1507500 lbf

140 kg

NCF 18/600 V

600 mm

730 mm

60 mm

644 mm

684 mm

696 mm

236250 lbf

573750 lbf

51.5 kg

NCF 28/600 V/HB1

600 mm

730 mm

78 mm

642 mm

685 mm

696 mm

353250 lbf

967500 lbf

67.5 kg

NCF 29/600 V

600 mm

800 mm

118 mm

662 mm

726 mm

754 mm

756000 lbf

1687500 lbf

165 kg

NCF 18/630 V

630 mm

780 mm

69 mm

681 mm

725 mm

739 mm

281250 lbf

652500 lbf

72.5 kg

NCF 28/630 V

630 mm

780 mm

88 mm

680 mm

728 mm

741.4 mm

436500 lbf

1125000 lbf

92.2 kg

NCF 29/630 V

630 mm

850 mm

128 mm

709 mm

788 mm

807 mm

841500 lbf

1946250 lbf

205 kg

NCF 18/670 V

670 mm

820 mm

69 mm

725 mm

769 mm

783 mm

292500 lbf

708750 lbf

74 kg

NCF 28/670 V

670 mm

820 mm

88 mm

724 mm

772 mm

783 mm

436500 lbf

1192500 lbf

98 kg

NCF 29/670 V

670 mm

900 mm

136 mm

748 mm

827 mm

846 mm

879750 lbf

2025000 lbf

245 kg

NCF 18/710 V

710 mm

870 mm

74 mm

767 mm

815 mm

831 mm

346500 lbf

843750 lbf

92.5 kg

NCF 28/710 V

710 mm

870 mm

95 mm

766 mm

818 mm

831 mm

524250 lbf

1417500 lbf

115 kg

NCF 29/710 V

710 mm

950 mm

140 mm

790 mm

876 mm

896 mm

965250 lbf

2250000 lbf

275 kg

NCF 18/750 V

750 mm

920 mm

78 mm

811 mm

863 mm

880 mm

396000 lbf

967500 lbf

105 kg

Unmatched Radial Load Capacity for Demanding Applications

Our Single Row Full Complement Cylindrical Roller Bearings are specifically engineered to manage extremely high radial loads. This exceptional capacity stems from their unique design, which incorporates a maximum number of cylindrical rollers. Without a cage, these rolling elements fill almost the entire internal space, distributing the load over a larger contact area. This design makes them indispensable in applications subject to heavy forces and shocks, where other bearing types might fail prematurely. They are a preferred choice for heavy machinery components.

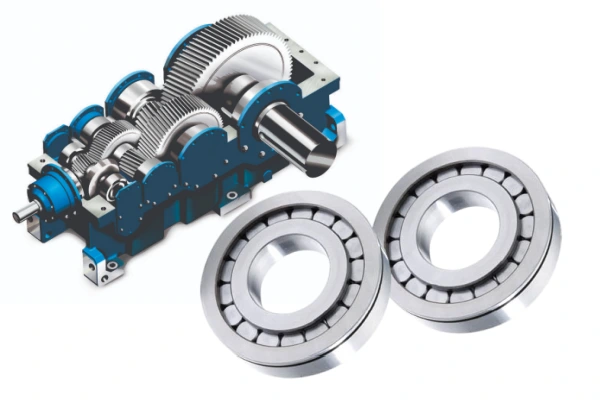

The robust construction of these cylindrical bearings ensures prolonged service life and consistent performance in the most challenging industrial environments. From large industrial gearboxes to critical rolling mill bearings, their ability to withstand constant, heavy radial loads is paramount. When designers need maximum performance from anti-friction bearings in a compact envelope, full complement designs offer an optimal solution.

Understanding the Design and Applications

The unique design of single row full complement cylindrical roller bearings makes them distinct from other roller bearing types. The cylindrical roller design, combined with the full set of rollers, means they can handle significant radial forces but cannot accommodate significant axial loads. This is an important consideration when selecting the right bearing for a specific application. Their primary purpose is to provide robust support and motion in high-load, low-to-moderate-speed scenarios.

These bearings are widely used across various industries, including mining, construction, and power generation. They are essential for applications like rolling mill bearings, gearbox bearings, and pumps, where durability and high load capacity are non-negotiable. Their ability to operate reliably under extreme conditions makes them a go-to choice for engineers and designers seeking a reliable solution for heavy-duty machinery components.

Quality and Durability: The TFL Difference in Cylindrical Roller Bearings

At TFL Bearings, we understand the critical role that quality and durability play in industrial applications. Our Single Row Full Complement Cylindrical Roller Bearings are manufactured to the highest standards, ensuring consistent performance and extended service life. We focus on precision engineering, using high-grade materials to withstand the toughest operating conditions. Our bearings undergo rigorous testing to meet stringent bearing specifications and industry requirements, giving you peace of mind.

Choosing the right bearing is crucial for optimal machinery performance. Our team of experts is dedicated to helping you select the perfect cylindrical bearing for your specific needs, considering factors such as radial load, operating speed, and environmental conditions. We provide comprehensive support, from selecting the correct bearing dimensions to ensuring proper bearing lubrication and installation.

FREQUENTLY ASKED QUESTIONS

What is a Single Row Full Complement Cylindrical Roller Bearing?

A Single Row Full Complement Cylindrical Roller Bearing is a type of roller bearing characterized by the absence of a cage. Instead, it features a maximum number of cylindrical rollers packed tightly together in a single row. This design choice allows for a significantly higher number of rolling elements compared to caged bearings of the same size, which directly translates into a much greater radial load carrying capacity. These anti-friction bearings are ideal for heavy-duty applications where space is limited and extreme radial forces are encountered, making them a robust component in industrial machinery.

What are the primary advantages of using Full Complement Cylindrical Roller Bearings?

The primary advantage of Full Complement Cylindrical Roller Bearings is their exceptionally high radial load capacity. Due to the increased number of rolling elements, they can withstand much heavier loads than standard caged cylindrical roller bearings of the same dimensions. This makes them highly durable and reliable in demanding environments. While their speed capabilities are generally lower, their robust construction also provides enhanced stiffness in the bearing arrangement. They are often chosen for their ability to handle shock loads effectively, providing extended service life in critical applications.

Do these bearings require special lubrication?

Standard industrial lubricants are sufficient, but ensuring proper lubrication intervals is crucial to prevent wear.

How can I select the correct bearing size?

You can use TFL’s bearing size chart or consult our experts for custom solutions based on your equipment needs.