TFL-Reliable Supplier of Electrically Insulated Bearings

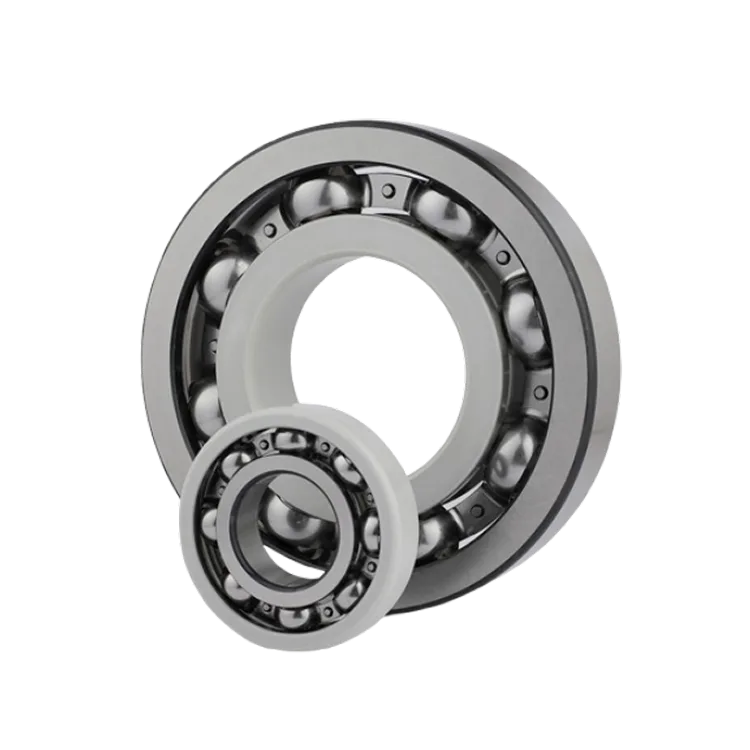

Electrically insulated bearings refer to a type of bearing that can prevent the passage of electric current. TFL offers insulation solutions such as ceramic coatings and ceramic rolling elements to provide reliable insulation protection for your equipment.

Why choose TFL bearings?

As an outstanding bearing manufacturer in China, TFL has been deeply engaged in the field of electrically insulated bearings for many years, offering a variety of electric insulation solutions. We provide effective protection for your bearings and significantly extend their service life.

-

Top

Product Category

Application

FAQ

Our Process

Hot Products

Support

Electrically Insulated Bearings Category

Eliminate Electrical Current Damage

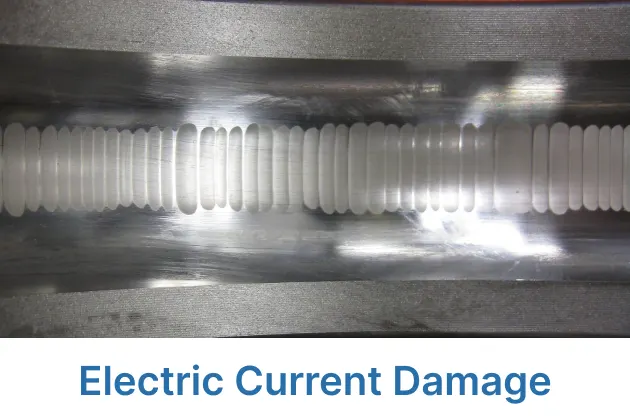

When the contact surface of the bearing needs to come into contact with current and become a conductive path for the current, especially in the mixed lubrication state of the bearing, even a small amount of current can cause damage to the bearing. Electrical corrosion marks will form on the bearing surface, greatly reducing the service life of the bearing.

Electrically insulated bearings can effectively solve this problem: their working principle involves establishing an insulating barrier on the bearing, which isolates current, preventing it from passing through the rolling elements and raceways and thereby fundamentally avoiding electrical corrosion. Even in a complex current environment, it can ensure the normal operation of the bearing.

The Four Core Advantages of Electrically Insulating Coated Bearings

In practical applications, users have various ways to prevent electrical damage. However, compared with solutions like grounding carbon brushes or insulated couplings, electrically insulated bearings are preferred by most users due to their cost-effectiveness and reliability:

- Significantly extend service life: Eliminate electrical corrosion from the source, allowing the bearing to reach its mechanical fatigue life, and extend the equipment’s operating time.

- Enhance equipment reliability: Significantly reduce unexpected downtime caused by bearing issues, ensuring continuous and stable operation of the production line.

- Reduce total cost of ownership (TCO): Although the initial investment is slightly higher, the long-term economic benefits are extremely high due to reduced replacement frequency, lower maintenance labor costs, and avoidance of production stoppage losses.

- Perfect compatibility and interchangeability: Our electrically insulated bearings have the same dimensions and tolerances as standard bearings, and can be directly replaced and installed without any modifications to your equipment (shafts or bearing housings).

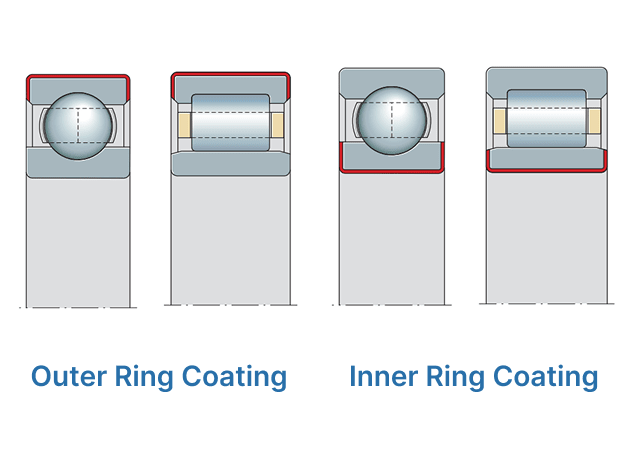

In addition to these four advantages, our electrical insulation coating also offers two insulation solutions: inner ring coating and outer ring coating. You can choose based on your actual working conditions.

Applications of Electrical Insulation

Electrically insulated bearings are crucial in any scenarios where electrical current could cause damage:

- Industrial motors: In various industrial motors, electrically insulated bearings can effectively prevent premature bearing failure caused by stray currents.

- Traction motors: In applications such as trains and other electric vehicles, traction motors often encounter currents that could damage standard bearings.

- Generators: During operation, generators produce electricity, and the internal bearings are at high risk of electrical corrosion.

- Variable frequency drive (VFD) applications: With the widespread use of VFDs, high-frequency bearing current damage has become the most common.

- Other special applications: In addition to the main fields mentioned above, electrically insulated bearings also play a role in other specialized applications, such as submersible pumps.

If your equipment is also troubled by electrical erosion damage, TFL electrically insulated bearings might be your ideal choice.

APPLICATION AREA

Medical Bearings

Medical Bearings The Medical Technology sector develops advanced equipment for diagnostics, treatment,

Marine Bearings

Marine Bearings The Marine Industry operates in one of the planet’s most demanding environments.

Agricultural Bearings

Agricultural Bearings The Agricultural Machinery sector is the backbone of global food production, uti

Heavy Equipment (Construction & Mining)

Heavy-Duty Bearings for Construction and Mining Equipment like excavators, bulldozers, loaders, cranes

INTERCHANGEABLE BRANDS

TFL Bearings: High quality bearings, an ideal choice to replace SKF and FAG.

WHY CHOOSE TFL

QUALITY

Market-proven with over 28 million bearings successfully delivered, and certified under multiple quality management systems, including ISO 9001.

PRICE

By integrating and leveraging China’s robust raw material supply chain, TFL is able to strictly control production costs, thereby offering highly competitive product prices.

FAST DELIVERY

With a vast inventory of over a million bearings, TFL offers solid assurance for your procurement needs. Common bearing models are ready for dispatch within just 48 hours.

FREQUENTLY ASKED QUESTIONS

Are the dimensions of electrically insulated bearings the same as those of ordinary bearings?

Yes, the external dimensions of electrical insulation bearings usually conform to international standards. This ensures good interchangeability with standard bearings, facilitating equipment upgrades and maintenance.

If you are unsure how to select the appropriate bearing, feel free to contact us at any time. Our bearing experts will provide you with selection and purchase advice.

How should I choose between coated insulated bearings and hybrid ceramic bearings?

Coated Insulated Bearings: Suitable for most applications, coated insulated bearings are the most cost-effective choice for most variable frequency motors and other applications.

Hybrid Ceramic Bearings: Ideal for equipment with high current frequencies or high requirements for speed and rigidity, hybrid ceramic bearings will offer you superior performance.

If you are unsure which type of bearing to choose, please contact us. TFL not only provides high-quality electrically insulated bearings but also offers professional purchasing advice.

What is the breakdown voltage of an electrically insulated bearing?

The breakdown voltage is the maximum voltage that the insulating coating of an electrically insulated bearing can withstand. Once the voltage applied between the inner or outer ring of the bearing exceeds this limit, the insulating layer will be "broken down", losing its insulating ability, and current will pass through the bearing, causing damage to it.

Generally, only coated insulated bearings have a breakdown voltage, and the industry standard is usually 1000V DC. Because hybrid ceramic bearings are theoretically infinitely insulating, in extreme cases, current will only discharge through the grease or air. Such extreme situations generally do not occur in industrial motors.

What payment methods do you offer?

We support multiple payment methods, including Letter of Credit (L/C), bank transfer (T/T), and PayPal, providing convenient options for customers worldwide.

OUR PROCESS

Contact

Initial Contact

01

Budgeting

Specialists Review

Needs

02

Options

Our Engineers Help YouChoose The RightBearings

03

Plant Visit

Option To Visit OurManufacturing Plant

04

Delivery

Your entire order is

delivered.

05

Support

We provide ongoingproduct support

06

HOT PRODUCTS

CAN’T FIND WHAT YOU NEED?

Please provide your question.

We’ll find you with the best support options.