Home / Product / Ball Bearings / Deep Groove Ball Bearings / Snap Ring Groove Ball Bearings

Snap Ring Groove Ball Bearings

The bearing with snap groove can be axially positioned in the bearing seat through the snap ring, significantly reducing the installation time and saving space.

Loading...

Total 784 Results

Part Number

Bore Dia

Outer Dia

Width

Locating Feature Bearing Outer Ring

Cage Material

Dynamic Radial Load

Static Radial Load

Max Speed

Weight

Price($)

6202-2ZNR/C3GJN

15 mm

35 mm

11 mm

Snap Ring (fitted)

Chrome Steel

1812 lbf

843 lbf

20000 rpm

45 g

2.4

6202-2ZNRJEM

15 mm

35 mm

11 mm

Snap Ring (fitted)

Chrome Steel

1812 lbf

843 lbf

20000 rpm

45 g

3.07

6202-RSNR

15 mm

35 mm

11 mm

Snap Ring (fitted)

Chrome Steel

1812 lbf

843 lbf

20000 rpm

45 g

2.53

6202-ZN/C3 HT22 VU082

15 mm

35 mm

11 mm

Snap Ring Groove

Chrome Steel

1812 lbf

843 lbf

20000 rpm

45 g

2.63

6202-ZNR

15 mm

35 mm

11 mm

Snap Ring (fitted)

Chrome Steel

1812 lbf

843 lbf

20000 rpm

45 g

2.51

6202ANR/C3

15 mm

35 mm

11 mm

Snap Ring (fitted)

Chrome Steel

1812 lbf

843 lbf

20000 rpm

45 g

3.19

6202NR/C3

15 mm

35 mm

11 mm

Snap Ring (fitted)

Chrome Steel

1812 lbf

843 lbf

20000 rpm

3.26

6202NRJ

15 mm

35 mm

11 mm

Snap Ring (fitted)

Chrome Steel

1812 lbf

843 lbf

20000 rpm

3.45

6003-2RS1NR

17 mm

35 mm

10 mm

Snap Ring (fitted)

Chrome Steel

1349 lbf

731 lbf

21000 rpm

39 g

5.35

6003-2RSHNR

17 mm

35 mm

10 mm

Snap Ring (fitted)

Chrome Steel

1349 lbf

731 lbf

21000 rpm

39 g

4.74

6003-2RSNRJEM

17 mm

35 mm

10 mm

Snap Ring (fitted)

Chrome Steel

1349 lbf

731 lbf

21000 rpm

39 g

4.74

6203 NR

17 mm

40 mm

12 mm

Snap Ring (fitted)

Stainless Steel

2237 lbf

1068 lbf

24000 rpm

0.065 kg

6203 NRJEM

17 mm

40 mm

12 mm

Snap Ring (fitted)

Chrome Steel

2237 lbf

1068 lbf

24000 rpm

0.065 kg

2.42

6203-2RS1NR

17 mm

40 mm

12 mm

Snap Ring (fitted)

Chrome Steel

2147 lbf

1079 lbf

17000 rpm

65 g

2.88

Snap Rings Takes More Axial Fixation Ability

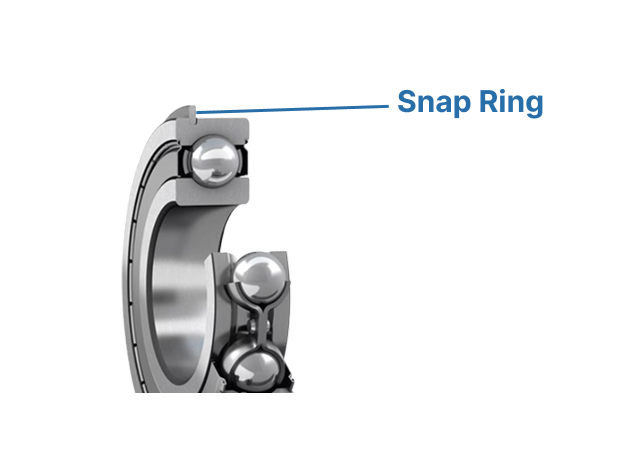

Snap ring groove ball bearing is a type of deep groove ball bearing with snap ring and snap groove.

The snap groove is generally located in the bearing outer ring. Snap ring with an opening can snap into the groove, becoming a little circlip ring on the bearing.

After the bearing installed, these small retaining rings will effectively limit the axial displacement of the bearing, thereby greatly increasing the axial fixing ability of this type of bearing and enabling the equipment to run smoothly.

More Stability & Less Maintenance

Deep droove bearing can bear the radial and axial loads themselves. The snap ring can further this advantage, and make the radial and axial loads on the bearing evenly distributed.

This kind of design can not only increase the stability of operation, but also decrease the wear during the movement of bearing components and reduce maintenance, thereby reducing the maintenance cost of bearings.

Make Installation Easier

Stop rings can replace traditional mechanical fixing methods, such as using nuts, rivets, etc. Compared with traditional mechanical fixing, the installation of stop rings is simpler and more convenient, and can be installed without special tools.

Before installation, only need to consider the inner diameter and overall thickness of the snap ring, making the bearing and equipment form a compact structure without unnecessary installation steps.

FREQUENTLY ASKED QUESTIONS

Does the purchase of bearings include a snap ring?

Generally, yes. Different models and suppliers provide different situations. Most manufacturers will pre-install the snap ring. You can confirm by the product details page on our website or contact us.

Can I use snap ring bearing in a housing that doesn't have a groove for the snap ring?

Yes, but it's not recommended. Without the snap ring, this bearing is just a deep groove ball bearing with a groove on outer ring. In other aspects, such as load capacity and RPS, it is the same as the standard deep groove ball bearing.

Is a special tool required for installing a snap ring?

Yes, mostly need snap ring pliers. This kind of plier has a special jaw, can expand or compress the snap ring safely, so that it can be inserted into or removed from the groove. It is not recommended to use ordinary pliers or screwdrivers.

Do your bearings meet international quality standards?

Yes, we are an ISO-certified bearing manufacturer, and all our bearings strictly comply with international quality standards.