Home / Product / Electrically Insulated Bearings / Electrically Insulated Deep Groove Ball Bearings / SKF INSOCOAT Deep Groove Ball Bearings

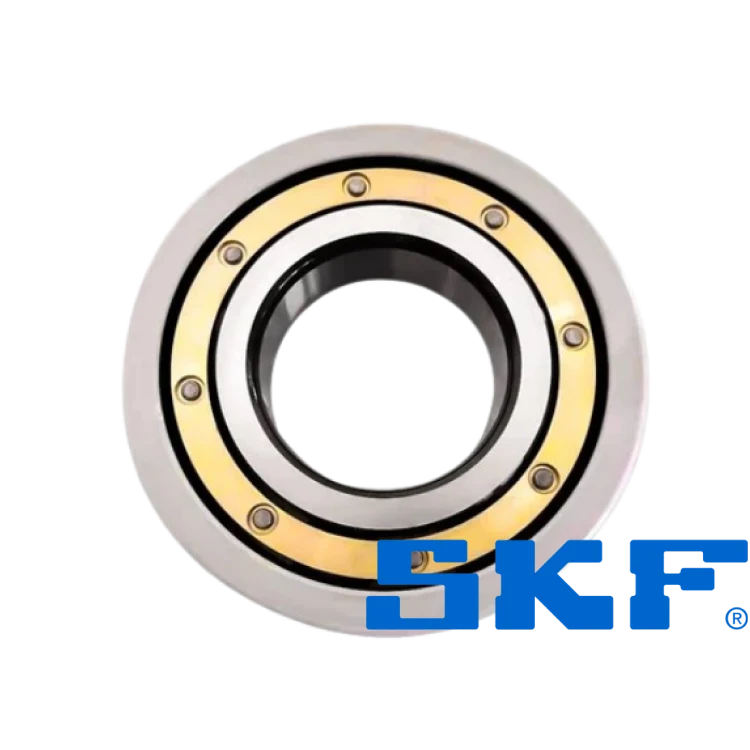

SKF INSOCOAT Deep Groove Ball Bearings

TFL provides high-quality alternative products compatible with SKF INSOCOAT , using the same alumina ceramic spraying process, with insulation performance up to 1000V DC, and provides a more cost-effective solution while ensuring dimensional interchangeability. Our electrically insulated deep groove ball bearings also have the advantages of high speed, low friction, and long life, making them an ideal choice for users who focus on balancing performance and budget.

Loading...

Total 144 Results

Model

Insulating Coating Types

Coating Suffix

Bore Diameter

Outside Diameter

Width

Basic Dynamic Load Rating

Basic Static Load Rating

Breakdown Voltage (DC)

Electrical Resistance

Cage Material

6309/C3VL0241

Insulation coating on outer ring

VL0241

45.0 mm

100.0 mm

25.0 mm

56.0 kN

31.5 kN

≤3000 V

200 MΩ

Sheet metal

6309/C4VL0241

Insulation coating on outer ring

VL0241

45.0 mm

100.0 mm

25.0 mm

56.0 kN

31.5 kN

≤3000 V

200 MΩ

Sheet metal

6310/C3VL0241

Insulation coating on outer ring

VL0241

50.0 mm

110.0 mm

27.0 mm

65.0 kN

38.0 kN

≤3000 V

200 MΩ

Sheet metal

6310M/C3VL0241

Insulation coating on outer ring

VL0241

50.0 mm

110.0 mm

27.0 mm

65.0 kN

38.0 kN

≤3000 V

200 MΩ

Brass cage

6311/C3VL0241

Insulation coating on outer ring

VL0241

55.0 mm

120.0 mm

29.0 mm

83.0 kN

47.5 kN

≤3000 V

200 MΩ

Sheet metal

6311M/C4VL0241

Insulation coating on outer ring

VL0241

55.0 mm

120.0 mm

29.0 mm

83.0 kN

47.5 kN

≤3000 V

200 MΩ

Brass cage

6311M/C3VL0241

Insulation coating on outer ring

VL0241

55.0 mm

120.0 mm

29.0 mm

83.0 kN

47.5 kN

≤3000 V

200 MΩ

Brass cage

6312/C3VL0241

Insulation coating on outer ring

VL0241

60.0 mm

130.0 mm

31.0 mm

85.2 kN

52.0 kN

≤3000 V

200 MΩ

Sheet metal

6312/C4VL0241

Insulation coating on outer ring

VL0241

60.0 mm

130.0 mm

31.0 mm

85.2 kN

52.0 kN

≤3000 V

200 MΩ

Sheet metal

6312M/C4VL0241

Insulation coating on outer ring

VL0241

60.0 mm

130.0 mm

31.0 mm

85.2 kN

52.0 kN

≤3000 V

200 MΩ

Brass cage

6312M/C3VL0241

Insulation coating on outer ring

VL0241

60.0 mm

130.0 mm

31.0 mm

85.2 kN

52.0 kN

≤3000 V

200 MΩ

Brass cage

6212M/C4VL0241

Insulation coating on outer ring

VL0241

60.0 mm

110.0 mm

22.0 mm

57.0 kN

36.5 kN

≤3000 V

200 MΩ

Brass cage

6212M/C3VL0241

Insulation coating on outer ring

VL0241

60.0 mm

110.0 mm

22.0 mm

57.0 kN

36.5 kN

≤3000 V

200 MΩ

Brass cage

6213/C4VL0241

Insulation coating on outer ring

VL0241

65.0 mm

120.0 mm

23.0 mm

63.0 kN

41.5 kN

≤3000 V

200 MΩ

Sheet metal

Beyond Bearing Protection: Enhancing Total System Integrity

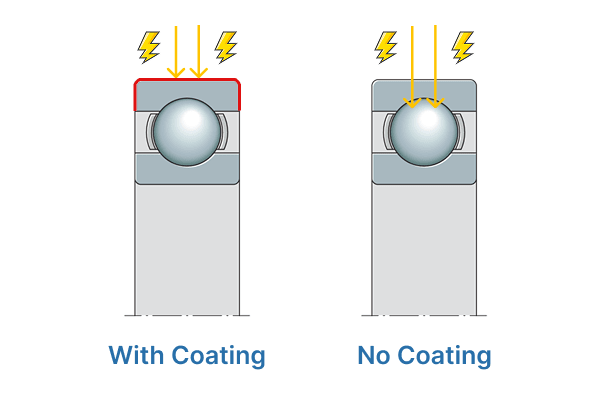

The damage from VFD-induced currents extends beyond the bearing itself. This high-frequency “electrical noise” can interfere with sensitive encoders, sensors, and control systems, leading to erratic performance and difficult-to-diagnose system faults.

Our insulated bearings do more than just protect themselves; they help create a cleaner, more stable electrical environment within your machinery. By providing a definitive block to the primary current path, they reduce the overall level of electrical noise conducted through the motor shaft. This system-level benefit is crucial in today’s increasingly automated and data-driven industries. Choosing our SKF INSOCOAT alternative is a holistic approach to improving not just mechanical reliability, but the integrity of your entire control system.

Meeting the Gold Standard as a Premier SKF INSOCOAT Alternative

When you search for SKF INSOCOAT deep groove ball bearings, you are seeking the industry’s gold standard for protection against electrical erosion. We engineered our insulated bearings with this exact benchmark in mind.

Our solution serves as a direct, high-performance alternative, providing the robust electrical insulation necessary to safeguard your critical machinery. At the core is a precision-applied aluminum oxide coating on the outer ring, which forms a formidable dielectric barrier. This barrier is guaranteed to block damaging stray currents from VFDs, effectively preventing the microscopic arcing that leads to premature bearing failure. By choosing our interchangeable insulated deep groove ball bearings, you are selecting a component that meets the demanding performance specifications of the INSOCOAT series, ensuring your equipment receives the highest level of protection without being tied to a single premium brand.

Premium Performance, Reallocate Your Budget Strategically

Opting for our electrically insulated deep groove ball bearings is not just a cost-saving measure; it’s a strategic financial decision.

We deliver performance and reliability that is directly comparable to the SKF INSOCOAT series but without the associated premium brand overhead. The significant cost savings you achieve can be reallocated to other critical areas of your business—whether it’s upgrading other components, investing in predictive maintenance technologies, or improving your bottom line. For procurement professionals and business owners, this transforms the purchasing decision from a simple part-for-part replacement into an opportunity to unlock value and enhance overall operational excellence. We empower you to achieve top-tier technical performance while making smarter use of your financial resources.

FREQUENTLY ASKED QUESTIONS

My SKF bearing has a VL0241 or VL0271 suffix. What is your equivalent?

These suffixes denote the location of the insulating coating.

- VL0241 typically indicates a standard coating on the outer ring's outer surface.

- VL0271 indicates a coating on the inner ring's bore.

We offer direct, interchangeable replacements for both configurations. Our bearing models directly use the same suffixes for easy search by you. You can use the filtering function on our product page or contact us directly. We will match the correct equivalent products based on the part numbers you provide, ensuring a perfect functional replacement for your specific application.

Can your insulated bearing prevent the specific failure mode known as "electrical fluting"?

Yes, absolutely. "Electrical fluting" is the specific term for the washboard-like patterns that form on bearing raceways due to the continuous passage of VFD-induced currents. It's a primary cause of noise, vibration, and eventual failure. Our ceramic coating creates a high-resistance barrier that physically blocks these currents from passing through the bearing. By stopping the current, you completely prevent the electrical discharge machining (EDM) that causes fluting. Our bearing is designed specifically to solve this exact problem.

How does high humidity or moisture affect the performance of your insulating coating?

Our ceramic coating is non-porous and chemically inert, making it highly resistant to moisture and humidity. Unlike some materials that can absorb water and lose their insulating properties, our aluminum oxide layer is completely impervious. Its high dielectric strength is unaffected by environmental humidity, ensuring that the bearing provides consistent and reliable electrical protection whether it's operating in a dry, climate-controlled room or a more humid industrial environment. This resilience is a key feature of its long-term reliability.

Do you offer samples? What is the Minimum Order Quantity (MOQ)?

Sample availability and Minimum Order Quantity (MOQ) can vary by product model. Please check the specific product page or contact our sales team for details on the bearing you need.