Home / Product / Electrically Insulated Bearings / Electrically Insulated Cylindrical Roller Bearings / FAG Current Insulated Single Row Cylindrical Roller Bearings

FAG Current Insulated Single Row Cylindrical Roller Bearings

FAG Current Insulated Single Row Cylindrical Roller Bearings offer a robust solution for applications where stray electrical currents can severely impact bearing life. These bearings feature a specially applied ceramic coating. This coating, typically made of aluminum oxide, acts as an effective electrical insulator. It prevents harmful currents from passing through the rolling elements, thereby protecting the lubricant from degradation and the raceways from electrical erosion, often referred to as “fluting.”

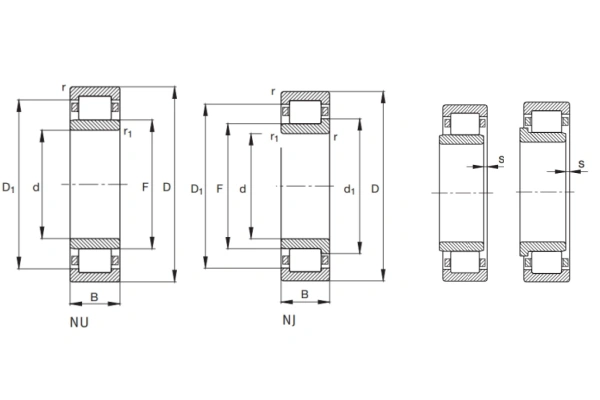

NU and NJ Series Bearings

FAG Current Insulated Single Row Cylindrical Roller Bearings are primarily divided into two structural types: NU series and NJ series. Each serves a distinct role in machinery.

The NU series features two flanges on the inner ring and no flanges on the outer ring. This design allows the shaft to move axially in both directions within the bearing, making it ideal for applications where thermal expansion occurs—such as the free end of electric motors or generators. It minimizes axial stress and prolongs bearing life under dynamic conditions.

The NJ series, on the other hand, has two flanges on the outer ring and one on the inner ring. This configuration supports axial positioning in one direction, making it suitable for fixed-end applications. It helps keep the rotating components stable and centered, especially in motors and transformers.

Both NU and NJ types provide effective mechanical support while offering electrical insulation in systems that are vulnerable to stray currents, making them a critical component in modern electric drive systems.

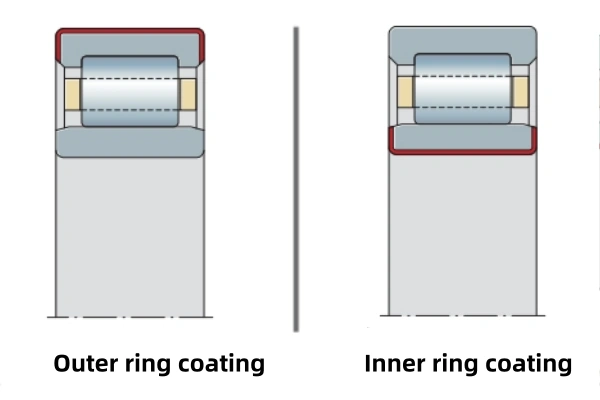

Inner vs. Outer Ring Insulation Coating

FAG insulated bearings use high-performance ceramic coatings to block current flow through the bearing. Depending on design requirements, insulation can be applied to either the inner ring or the outer ring, identified by coating types J20AA and J20B, respectively.

The J20B coating is applied to the outer ring. It is the most common configuration and suitable for most applications where outer ring insulation is sufficient. The coating layer is typically 200 μm thick, offering strong resistance to electric breakdown, humidity, and corrosion.

The J20AA coating, applied to the inner ring, is used when installation space or mechanical layout limits access to the outer ring. Like J20B, it also offers excellent insulation performance and long service life.

Both coatings are applied using plasma spray technology, where aluminum oxide powder is melted and sprayed at high velocity onto the surface. The substrate is pre-treated for bonding strength, and the ceramic layer is then sealed for added durability.

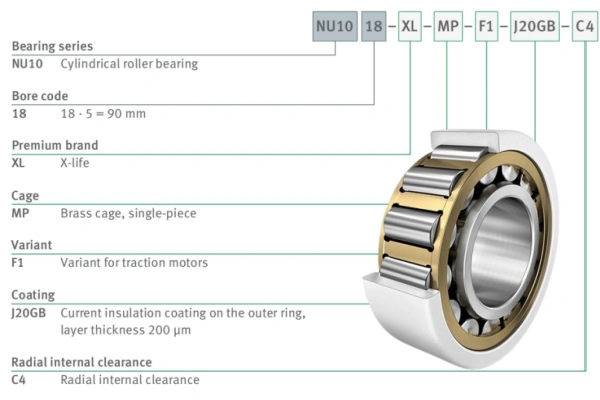

Decoding Bearing Designations and Critical Applications

Understanding the designation of FAG Current Insulated Single Row Cylindrical Roller Bearings is crucial for proper selection and application. Each part of the bearing code conveys specific information.

For instance, a typical designation might include elements like the bearing series (e.g., NU10), the bore diameter (e.g., 18 for a 90mm bore), and details about the internal design. Critically, the current insulation feature is identified by specific suffixes, such as “J20GB” which signifies a ceramic coating on the outer ring with a certain thickness, or “J20A” for an inner ring coating. Other suffixes can indicate the cage type, clearance (e.g., C4 for greater than normal radial clearance), or special performance characteristics.

These FAG insulated bearings are vital components in a wide range of critical applications where stray electrical currents are a concern. Key applications include electric motors and generators, particularly those driven by variable frequency drives (VFDs), wind turbines, and railway traction motors. In these environments, they effectively prevent electrical erosion of raceways, lubricant degradation, and premature bearing failure, thereby significantly enhancing the reliability and service life of the machinery.

For instance, a typical designation might include elements like the bearing series (e.g., NU10), the bore diameter (e.g., 18 for a 90mm bore), and details about the internal design. Critically, the current insulation feature is identified by specific suffixes, such as “J20GB” which signifies a ceramic coating on the outer ring with a certain thickness, or “J20A” for an inner ring coating. Other suffixes can indicate the cage type, clearance (e.g., C4 for greater than normal radial clearance), or special performance characteristics.

These FAG insulated bearings are vital components in a wide range of critical applications where stray electrical currents are a concern. Key applications include electric motors and generators, particularly those driven by variable frequency drives (VFDs), wind turbines, and railway traction motors. In these environments, they effectively prevent electrical erosion of raceways, lubricant degradation, and premature bearing failure, thereby significantly enhancing the reliability and service life of the machinery.

FREQUENTLY ASKED QUESTIONS

How do I know whether to use NU or NJ series bearings?

NU series allows axial displacement in both directions, ideal for free-end bearings. NJ series allows axial location in one direction, used as locating bearings.

What's the difference between J20B and J20AA coatings?

J20B is used on the outer ring, while J20AA is for the inner ring. Both are ceramic coatings applied by plasma spraying and provide similar electrical insulation.

Where are FAG Current Insulated Single Row Cylindrical Roller Bearings typically applied?

They are primarily used in electric motors, generators, wind turbines, and railway traction motors, as well as other industrial machinery where variable frequency drives are used or where there's a risk of stray currents causing bearing damage.

Are the dimensions of FAG Current Insulated Bearings different from standard, non-insulated bearings?

No, FAG Current Insulated Single Row Cylindrical Roller Bearings are designed to be dimensionally interchangeable with their standard, non-insulated counterparts. The ceramic coating is a very thin layer (typically 120 μm or 200 μm), which means the overall boundary dimensions (bore diameter, outer diameter, and width) of the insulated bearings conform to ISO standards. This ensures that they can be directly installed as replacements for standard bearings in existing machinery without requiring any design modifications to the housing or shaft.