Home / Product / Roller Bearings / Needle Roller Bearings / One-Way Needle-Roller Bearing Clutches

One-Way Needle-Roller Bearing Clutches

One-way needle-roller bearing clutches offer high torque transmission, compact design, and smooth one-directional operation. They are ideal for transmissions, gear systems, and other rotating mechanisms where backstop or overrunning features are required.

Loading...

Total 66 Results

Part Number

Interchangeable

Bore Dia

Outer Dia

Width

System of Measurement

Construction

Knurled

Seal Type

Series

Spring Material

Torque Capacity

Weight

EWC0608C

INA

6 mm

10 mm

8 mm

Metric

Single Row

Open

EWC Series

Plastic

0.44 Nm

1.7 g

EWC0608XA

INA

6 mm

10 mm

7.5 mm

Metric

Single Row

Open

EWC Series

Plastic

0.25 Nm

1.7 g

EWC0608XC

INA

6 mm

10 mm

7.5 mm

Metric

Single Row

Open

EWC Series

Plastic

0.44 Nm

1.7 g

HF0612

INA

6 mm

10 mm

12 mm

Metric

Single Row

No

Open

HF Series

Steel

1,76 Nm

3 g

HF0612-KF

INA

6 mm

10 mm

12 mm

Metric

Single Row

No

Open

HF Series

Plastic

1,76 Nm

3 g

HF0612-KF-R

INA

6 mm

10 mm

12 mm

Metric

Single Row

Yes

Open

HF Series

Plastic

0.6 Nm

3 g

HF0612-R

INA

6 mm

10 mm

12 mm

Metric

Single Row

Yes

Open

HF Series

Steel

0.6 Nm

3 g

HFL0606-KF-R

INA

6 mm

10 mm

6 mm

Metric

Triple Row

Yes

Open

HFL Series

Plastic

0.5 Nm

1 g

HFL0615

INA

6 mm

10 mm

15 mm

Metric

Triple Row

No

Open

HFL Series

Steel

1.76 Nm

4 g

HFL0615-KF

INA

6 mm

10 mm

15 mm

Metric

Triple Row

No

Open

HFL Series

Plastic

1.76 Nm

4 g

HFL0615-KF-R

INA

6 mm

10 mm

15 mm

Metric

Triple Row

Yes

Open

HFL Series

Plastic

0.6 Nm

4 g

HFL0615-R

INA

6 mm

10 mm

15 mm

Metric

Triple Row

Yes

Open

HFL Series

Steel

0.5 Nm

4 g

1WC0812

INA

8 mm

14.2 mm

12 mm

Metric

Single Row

Open

1WC Series

Steel

1.96 Nm

7 g

1WC0815

INA

8 mm

14.2 mm

14.5 mm

Metric

Single Row

Open

1WC Series

Steel

2.65 Nm

8 g

What Is a One-Way Needle-Roller Clutch?

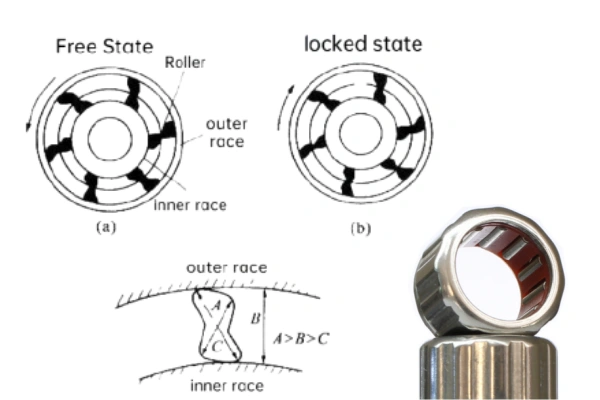

A one-way needle-roller clutch is a mechanical device that allows torque to be transmitted in one direction while allowing free rotation in the opposite direction. It is composed of needle rollers, a cage, an outer ring, and a cam or sprag surface. When the input shaft rotates in the drive direction, the rollers are wedged tightly, transferring torque. In the opposite direction, the rollers release, allowing free motion.

This clutch is commonly used in backstop, overrunning, and indexing applications, making it essential in various machinery. Because of their compact structure and ability to handle high loads, they are widely used in gearboxes, starters, and other one-way gear mechanisms.

This clutch is commonly used in backstop, overrunning, and indexing applications, making it essential in various machinery. Because of their compact structure and ability to handle high loads, they are widely used in gearboxes, starters, and other one-way gear mechanisms.

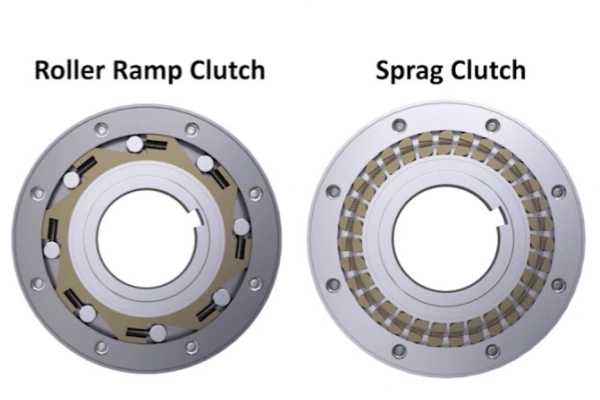

Sprag vs. Roller Clutch: What's the Difference and When to Use Each?

Sprag clutches and roller clutches are both types of one-way clutch bearings, but they operate differently. A sprag clutch uses small, curved elements called sprags that tilt to engage with the inner and outer rings. This design provides fast locking, high torque capacity, and smooth engagement even at high speeds.

On the other hand, roller clutches use cylindrical rollers that lock when forced into a wedge-shaped raceway. They are simpler in design and are often more cost-effective for applications with lower torque and speed demands.

When to use:

- Use sprag clutch bearings for high-speed, high-torque applications like automatic transmissions and heavy machinery.

- Use roller clutches in medium or low-speed operations like conveyor belts or small motors.

Applications of One-Way Clutch Bearings in Modern Machinery

One-way clutch bearings are critical in systems where rotational direction must be controlled. They prevent reverse rotation, reduce wear, and improve power efficiency. These bearings are essential in sectors such as:

– Automotive transmissions, where sprag clutches help shift gears smoothly and prevent rollback.

– Power tools, where they maintain torque direction and ensure user safety.

– Printing machinery, where precise indexing is crucial.

– Textile equipment, which requires continuous motion in one direction.

– Conveyors and elevators, where they serve as backstops to prevent reverse motion.

– Automotive transmissions, where sprag clutches help shift gears smoothly and prevent rollback.

– Power tools, where they maintain torque direction and ensure user safety.

– Printing machinery, where precise indexing is crucial.

– Textile equipment, which requires continuous motion in one direction.

– Conveyors and elevators, where they serve as backstops to prevent reverse motion.

FREQUENTLY ASKED QUESTIONS

What is a sprag clutch and how does it work?

A sprag clutch is a type of one-way clutch that uses curved wedges (sprags) to lock rotation in one direction. When rotation occurs in the driving direction, the sprags tilt and wedge tightly between the races, transmitting torque. In the opposite direction, they disengage, allowing free movement. This design provides fast engagement and is ideal for high-speed, high-load systems like automatic transmissions.

What’s the difference between one-way clutch bearings and standard ball bearings?

Unlike standard ball bearings that support rotation in both directions, one-way clutch bearings are designed to lock in one direction and allow free motion in the other. They are typically used in systems requiring overrunning, indexing, or backstop functions, such as in gearboxes, motor drives, or starter mechanisms.

What are the main benefits of using a one-way clutch bearing?

The main benefits include precise control over rotational direction, compact design for space-saving, high torque capacity relative to size, immediate engagement without backlash, and durability for long-term use in various applications.

Can one-way needle bearings handle high loads?

Yes, one-way needle bearings, particularly those designed as one-way needle-roller bearing clutches, are engineered to handle significant radial and axial loads. Their design with multiple needle rollers distributes the load effectively, making them suitable for high-load, high torque one way bearing applications.