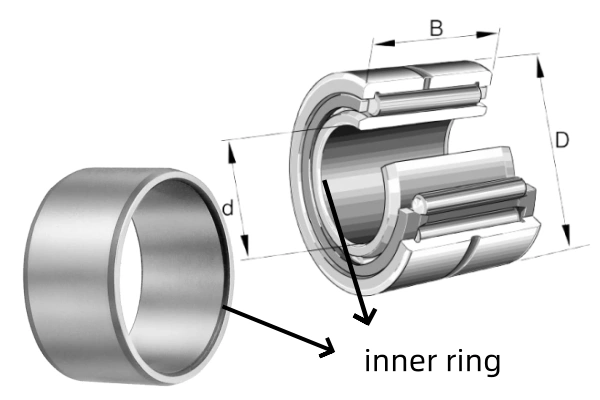

Inner Rings for Needle Roller Bearings

What Are Inner Rings in Needle Roller Bearings?

Inner rings, sometimes referred to as inner race bearings or bearing inner rings, are cylindrical components made of hardened steel. They serve as the rolling surface when a shaft is too soft or irregular to be used directly as a raceway. In needle roller bearings, this is especially important because the rollers are thin and require a very smooth, hard surface to perform properly.

TFL’s inner rings are manufactured with high dimensional accuracy, consistent surface finish, and proper hardness to ensure reliable rotation, even under heavy loads. These needle bearing inner races extend the lifespan of bearings and prevent damage to shafts.

When selecting a bearing setup, choosing the right inner ring is essential for optimizing load distribution, alignment, and bearing life.

Applications of Inner Rings in Industrial Machinery

Needle roller bearing inner rings are widely used in various machinery where compact design, high load capacity, and precise movement are critical. These applications include automotive transmissions, agricultural equipment, gearboxes, and power tools.

In many cases, the shafts in these machines are not hardened or ground, which means that an inner ring is necessary to create a suitable rolling path for the needle rollers. TFL’s bearing inner rings ensure consistent operation even in high-speed or oscillating conditions.

Another benefit is ease of maintenance: replacing a worn inner ring is simpler and more cost-effective than replacing the entire shaft or bearing unit. TFL inner rings are available in both metric and inch sizes, with optional lubrication holes or grooves for specific engineering needs.

Compatibility with Koyo and Other Industry Standards

TFL Bearings offers inner rings that are dimensionally interchangeable with leading brands such as Koyo inner ring series. This means that you can easily integrate TFL products into existing systems without needing major design modifications.

Our needle bearing inner rings meet ISO and DIN standards for tolerance and hardness. This makes them suitable for replacement, OEM, or customized engineering applications. If your machine already uses Koyo components, TFL’s equivalents provide a reliable and cost-effective alternative.

We also offer complete technical support and engineering drawings for each product, ensuring confidence in every application. Whether you’re repairing, upgrading, or designing new equipment, TFL’s compatibility and quality give you flexibility and peace of mind.

FREQUENTLY ASKED QUESTIONS