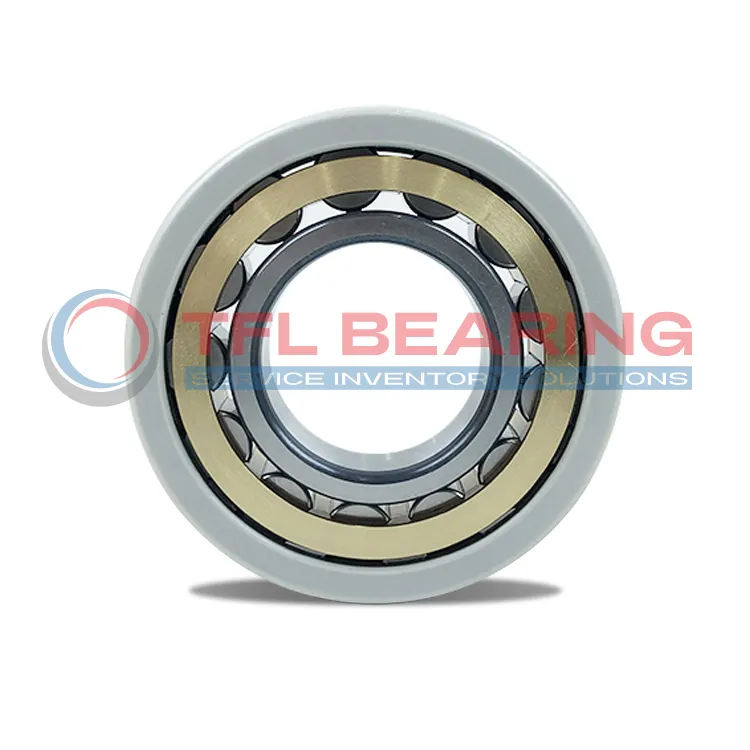

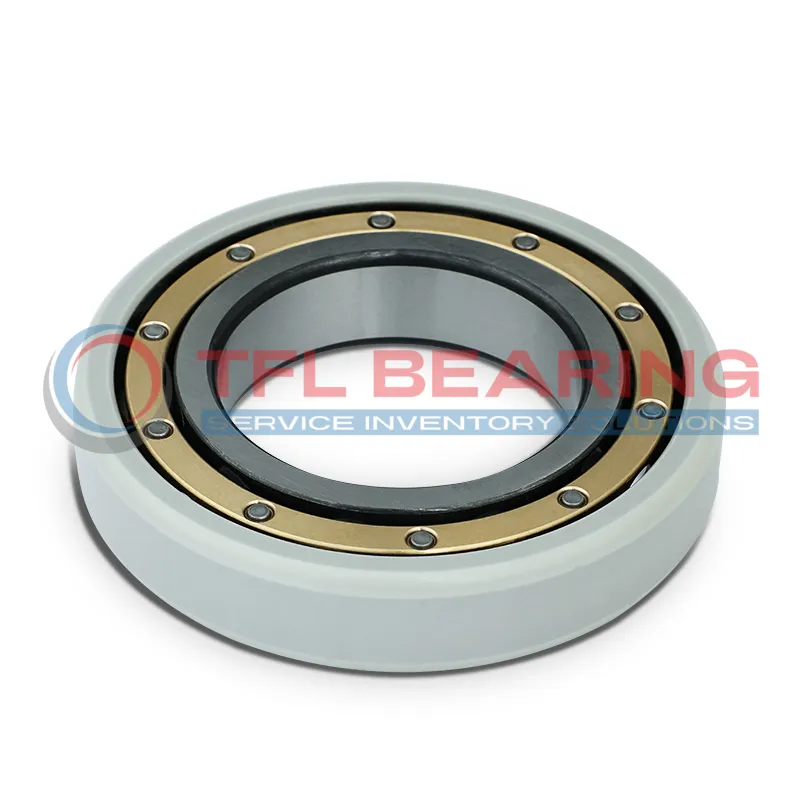

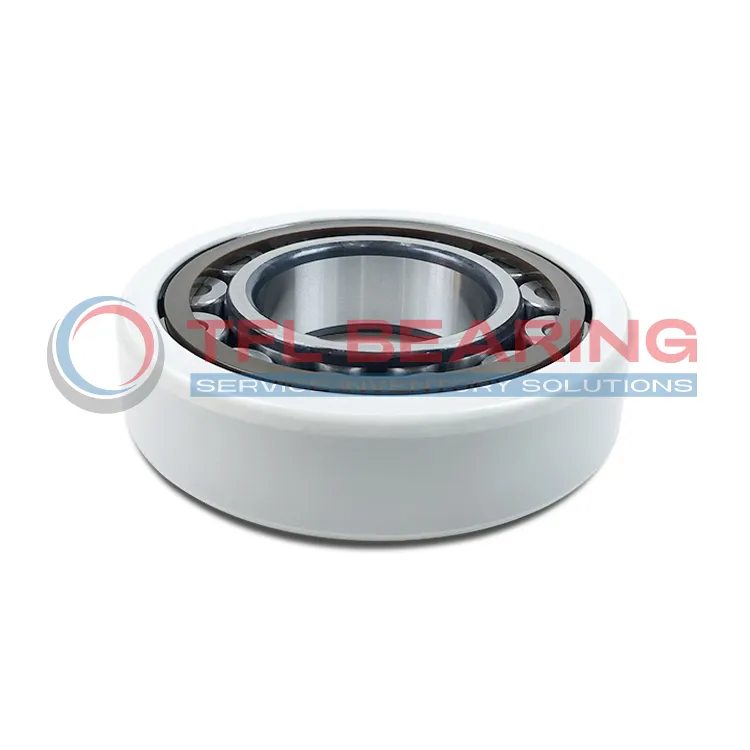

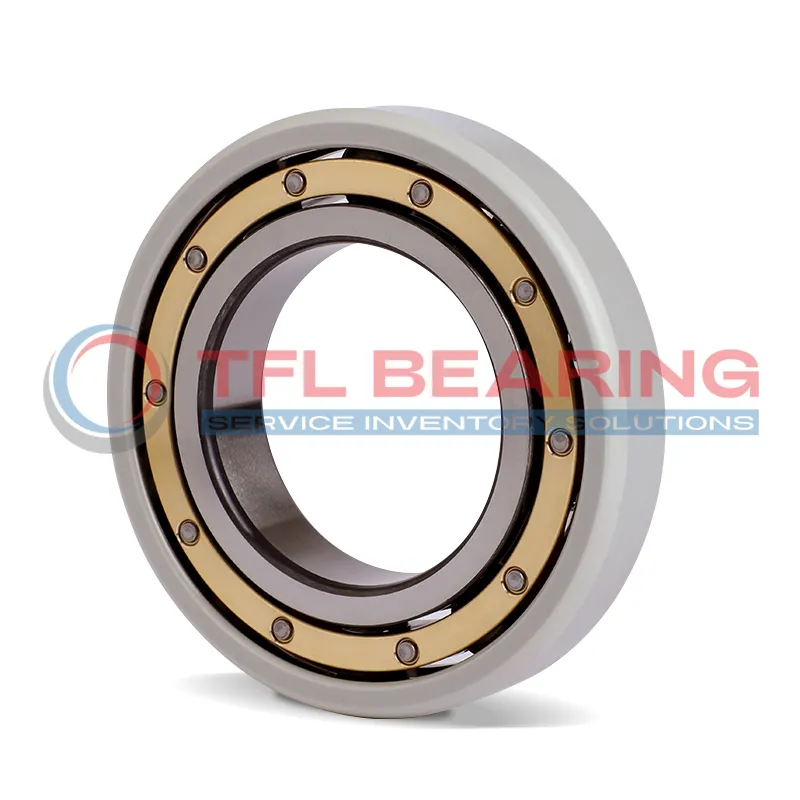

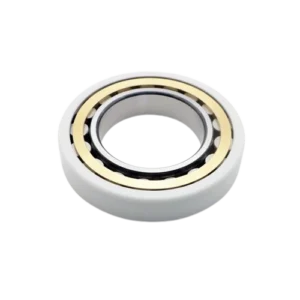

Electrically Insulated Cylindrical Roller Bearings

Why Choose TFL Bearings

-

Top

Product Category

Application

FAQ

Our Process

Hot Products

Support

Roller Bearings Category

Protection from Electrical Damage

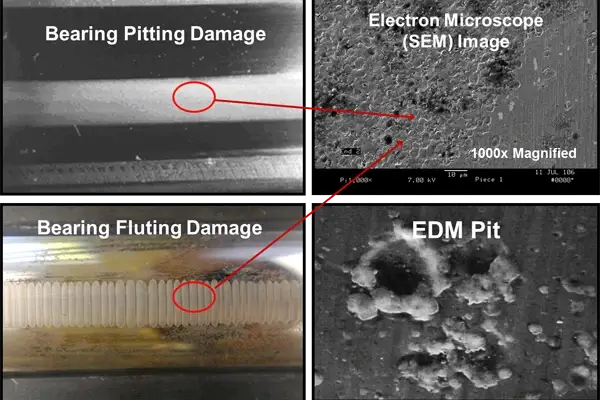

In many electric motor and generator applications, shaft voltage is a common issue. These voltages, if not properly managed, can pass through the bearing, creating electrical discharges. Over time, this leads to surface damage like fluting, pitting, and electrical erosion, which shorten bearing life dramatically.

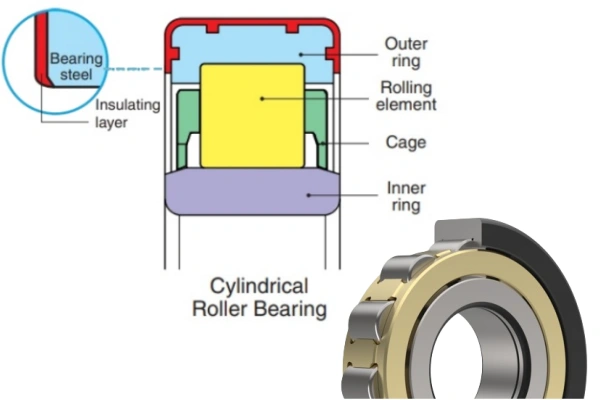

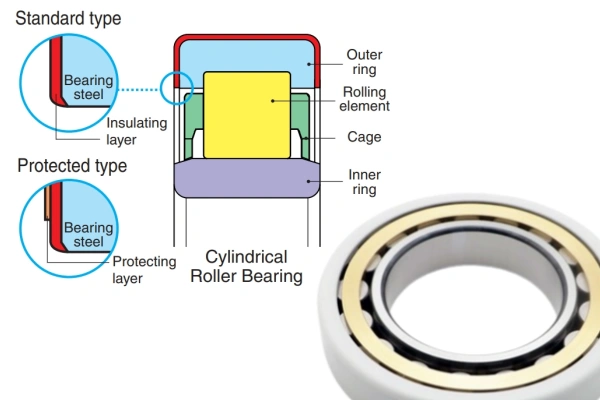

Electrically Insulated Cylindrical Roller Bearings are specifically designed to stop this process. By applying a non-conductive coating to the bearing’s outer or inner ring, they break the electrical circuit and isolate the shaft from ground current paths. This insulation is highly effective in preventing electric current from damaging internal surfaces.

This protective feature is essential in modern systems that use variable speed drives (VSDs), where high-frequency switching increases the risk of shaft current. Using insulated bearings reduces the need for extra grounding systems and protects sensitive components.

Advanced Insulation Coatings

The core technology behind Electrically Insulated Cylindrical Roller Bearings lies in the insulation layer. The most widely used method is plasma-sprayed ceramic coating, typically applied to the outer ring. This coating forms a hard, dense, and uniform insulating barrier that resists voltages up to 1000V or higher.

Ceramic coatings are extremely durable, resistant to moisture and wear, and can withstand harsh environments such as humid or dusty industrial settings. For special applications, polymer-based coatings may be used, offering lighter weight and good dielectric properties.

Regardless of the type, each insulating layer must meet strict quality controls. Surface finish, thickness uniformity, and adhesion strength all affect performance. At TFL, we ensure every coating meets international standards for insulation resistance and mechanical durability.

Reliable Performance in Variable Speed Systems

As industries move toward smart and energy-efficient systems, Electrically Insulated Cylindrical Roller Bearings are becoming indispensable in equipment powered by Variable Frequency Drives (VFDs). These drives allow for speed control but often cause voltage imbalances and bearing currents.

Without insulation, these currents find a path through the bearings, especially in motors with high switching frequencies. Over time, this leads to surface damage, increased noise, and early failure.

Insulated bearings act as a barrier to these high-frequency currents. They are now widely used in compressors, pumps, wind turbines, railway traction motors, and other mission-critical systems. Their presence ensures stable operation, energy efficiency, and extended service life.

APPLICATION AREA

Railway Bearings

Railway Bearings Locomotives, passenger cars, freight wagons (railcar), and track maintenance equipmen

Heavy Equipment (Construction & Mining)

Heavy-Duty Bearings for Construction and Mining Equipment like excavators, bulldozers, loaders, cranes

Industrial Bearings

The Industrial Machinery & Manufacturing sector forms the backbone of modern production, encompass

Energy Sector & Power Generation

Power Plant Bearings The Energy Sector powers our world, using complex machinery like wind turbines, g

INTERCHANGEABLE BRANDS

TFL Bearings: High quality bearings, an ideal choice to replace SKF and FAG.

WHY CHOOSE TFL

QUALITY

PRICE

FAST DELIVERY

FREQUENTLY ASKED QUESTIONS

In what industries are these bearings typically used?

- Electric motors and generators

- Variable Frequency Drive (VFD) systems

- Traction motors for trains

- HVAC systems

- Wind power generators

- Pumps and compressors

In these environments, insulation is essential to avoid premature failure caused by shaft currents. These bearings ensure smooth operation and reduce maintenance intervals, especially in high-speed and high-load applications.

What is the difference between insulated bearings and hybrid ceramic bearings?

- Electrically Insulated Cylindrical Roller Bearings retain a full steel construction and use a coated insulation layer (ceramic or polymer) on the rings.

- Hybrid ceramic bearings use ceramic rolling elements (usually silicon nitride) with steel rings.

Insulated bearings are typically more cost-effective and widely used in general industrial motors, especially where only ring insulation is needed. Hybrid bearings are preferred in very high-speed or high-precision applications but come at a higher cost.

What insulation voltage levels can these bearings withstand?

At TFL, we apply strict testing to verify insulation resistance across all our products. This ensures the bearings perform reliably even under frequent voltage spikes, which are common in inverter-controlled systems.

Does TFL Bearings support custom solutions for insulated bearings?

OUR PROCESS

Initial Contact

Specialists Review

Needs

Our Engineers Help YouChoose The RightBearings

Option To Visit OurManufacturing Plant

Your entire order is

delivered.

We provide ongoingproduct support

HOT PRODUCTS

CAN’T FIND WHAT YOU NEED?

Please provide your question.

We’ll find you with the best support options.