Modern motors and industrial systems increasingly use variable frequency drives (VFDs), inverter-fed drives, and high-speed electronics that generate stray electrical currents. These currents often pass through bearings, causing electrical erosion, fluting, pitting, and ultimately early bearing failure. These failures are even more common in humid or coastal environments, or where the equipment runs 24/7. Standard bearings — even premium ones — often fail to withstand these conditions.

Electric insulated bearings effectively block current paths by applying an insulating coating to the bearing surface, thereby protecting the bearings from electro-corrosion. However, the manufacturing process for electric insulated bearings is complex and highly demanding technologically, with only a limited number of manufacturers worldwide capable of supplying high-quality insulated bearings. In this context, TFL Bearings from China is becoming the preferred partner for global OEMs due to its exceptional technical strength and reliable product quality.

What Electric Insulated Bearings Solve

Electric insulated bearings are specifically designed to protect against stray currents. They provide:

- An insulated barrier (ceramic or oxide coating) to stop current from flowing through the bearing

- High resistance to voltage spikes

- Reliable operation in humid or corrosive environments

- A longer operational life and lower lifecycle cost

Common types include:

- Deep Groove Ball Bearings (e.g. 6205, 6206, 6309)

- Angular Contact Ball Bearings (e.g. 7206, 7210)

- Cylindrical Roller Bearings (e.g. NU308, NU322)

Why Global OEMs Are Sourcing from China

The global supply of truly high-performance electric insulated bearings is still quite limited. Many Western and Japanese OEMs and bearing producers do offer insulated bearings, but often with higher prices, longer lead times, lower coating thicknesses, or limited customization.

TFL Bearings: A Leader in Electric Insulated Bearings

TFL Bearings is a full-service insulated bearing manufacturer based in China. We specialize in R&D, production, and global distribution for industrial OEM clients.

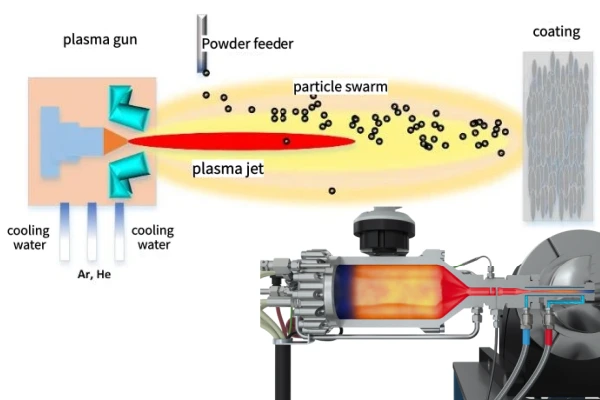

Superior Ceramic Coating Technology

TFL bearings utilizes advanced plasma spraying technology. We apply a high-performance aluminum oxide (Al2O3) ceramic coating to the outer or inner ring surface. The coating thickness is precisely controlled between 50-300 microns, ensuring excellent uniformity and consistency.

Unlike uneven coatings on the market, TFL’s unique low porosity and high dielectric strength provide superior insulation. This is achieved even at relatively thinner applications. Our coatings ensure reliable voltage resistance, effectively preventing electrical erosion caused by current passing through the bearing. This significantly extends bearing service life in harsh operating conditions.

In our laboratory tests, even in humid or extreme environments, our insulating coating maintains stable insulation resistance, ensuring the bearing operates normally and does not fail due to moisture, thus preventing unexpected equipment downtime.

Precision Manufacturing for Stable Performance

As a comprehensive insulated bearing manufacturer integrating R&D, design, production, and sales, TFL Bearings boasts a full suite of modern production lines and high-precision inspection equipment.

- Comprehensive Production Equipment: We are equipped with a series of precision processing equipment such as imported German Schenck super-finishing grinders, high-precision CNC lathes, and advanced thermal spraying equipment, ensuring bearing dimensional accuracy and surface finish reach P5 or higher grade.

- Advanced Inspection Technology: Before leaving the factory, every batch of electric insulated bearings undergoes rigorous insulation performance testing, dimensional accuracy inspection, vibration and noise testing, and other checks. During insulation tests, our bearings can typically withstand a continuous high voltage of 3000V and achieve an insulation resistance of over 20GΩ, far exceeding industry standards.

For example, we tested a batch of TFL-6320M/C3VL0241 bearings, and after thermal spray treatment, the insulation resistance increased by an average of over 90%, and they remained un-punctured even when subjected to 1000V for over 5 seconds.

Quantified Test Results

Real-world lab and customer application tests show our bearings retain high insulation resistance under humid, high-voltage conditions.

| Sample | Bearing Type | Voltage | Coating Thickness | Initial Resistance | After Humidity Test (5000 hrs) | Resistance Drop |

|---|---|---|---|---|---|---|

| #1 | 6205CE | 1000V | ~200 µm | 27.32 GΩ | 26.51 GΩ | 3.0% |

| #2 | 6309CE | 1000V | ~200 µm | 21.50 GΩ | 20.13 GΩ | 6.4% |

| #3 | NU322CE | 1000V | ~200 µm | 25.48 GΩ | 24.01 GΩ | 5.8% |

- All samples operated continuously for 5000 hours at 95% relative humidity. No micro-cracks or breakdowns occurred in the coating.

- During exposure tests in the humidity chamber, the insulation performance of these customized products remained stable, with no recorded equipment downtime.

This proves that TFL bearings’ insulating coating can withstand high stress during actual installation and use without damage, ensuring long-term, stable insulation performance.

Competitive Benchmarking

TFL insulation thickness and resistance are on par or superior to global leaders like:

But with:

- Faster delivery

- More flexible customization

- OEM-friendly pricing

OEM Success Case: Southeast Asia Pump Manufacturer

A leading pump OEM in Southeast Asia had recurring motor failures due to shaft currents in coastal humidity.

After switching to TFL Insulated Bearings (Model 6216M/C4VLO241):

| Metric | Before | After TFL |

|---|---|---|

| Failure Cycle | Every 5 months | 24+ months |

| Downtime | ~10 hrs/month | <5 hrs/year |

| Maintenance Cost | $50,000/year | <$10,000/year |

Conclusion

Global OEMs are realizing that choosing a technically proficient and reliable Chinese bearing factory can not only solve supply challenges but also provide superior cost-effectiveness and customization services. TFL Bearings is your ideal partner. We specialize in providing high-quality electric insulated bearings and various other custom bearings to B2B clients, ensuring your equipment operates stably in any demanding environment.

Contact TFL Bearings Today for Your Exclusive Solution!

Your equipment deserves the best protection. If you are looking for reliable, efficient, and cost-effective electric insulated bearing solutions, TFL Bearings is your ideal choice. Click on the pop-up window in the sidebar now or send an email to our sales team to receive a free consultation and quotation from our professional engineers. Discover how TFL Bearings can help your business achieve success!