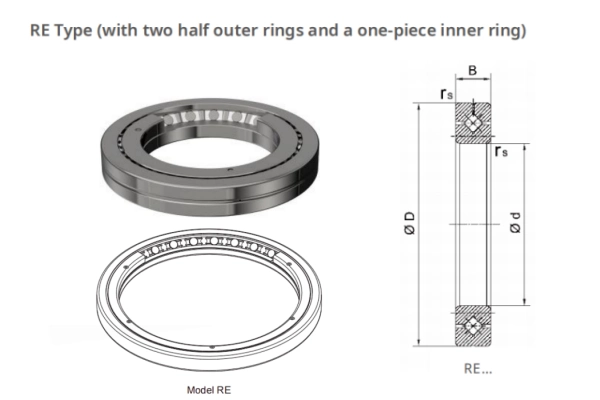

RE Crossed Roller Bearings

Structural Advantages of RE Crossed Roller Bearings

RE Crossed Roller Bearings are characterized by a separable outer ring and a split inner ring, which allows for simplified installation and optimized adjustment during assembly. This design reduces internal stress caused by uneven mounting and ensures stable rotation accuracy.

In comparison to the RB type, RE bearings reverse the inner and outer ring separation, making them more suitable for mechanisms where the outer ring rotates, such as rotary tables and gimbals. Their rigid outer ring ensures minimal deformation during load application.

Applications in High-Precision Machinery

Due to their excellent rigidity and compact design, RE Crossed Roller Bearings are widely used in rotary table bearings, robot joints, aerospace bearings, and other thin section bearings applications. They provide excellent performance in environments that require high precision and low torque fluctuation.

Their compact and integrated structure allows them to be used in limited spaces, making them ideal for high-performance machinery where space-saving is essential. The RE series also reduces the need for additional fixing parts, simplifying assembly.

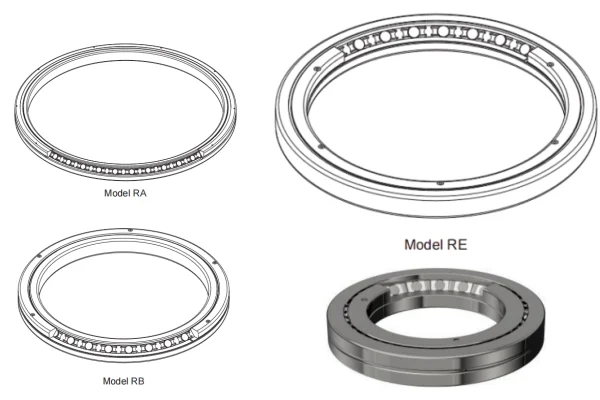

Differences Between RE and Other Crossed Roller Bearing Types

Compared to RA or CRBS types, which are ultra-thin and used in robot bearings, the RE type offers higher rigidity and is better suited for applications where strength and support under load are prioritized. While other types may be used in lightweight designs, the RE series excels in durability and support.

FREQUENTLY ASKED QUESTIONS