RB Crossed Roller Bearings

Structural Benefits & Design Philosophy

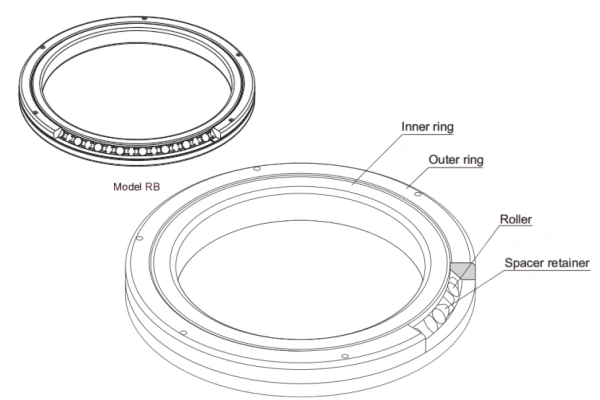

The RB series is a fundamental type of crossed roller bearings. The design features a two-piece outer ring and a one-piece inner ring. This configuration is meticulously engineered for applications that primarily involve inner ring rotation while demanding high precision. The separable outer ring makes installation and assembly more manageable in certain setups, allowing for easier integration into complex machinery. This design also contributes to the bearing’s overall stability and rigidity, which is crucial for maintaining accuracy under varying load conditions.

Furthermore, the V-groove raceway and spacer system ensure the smooth and quiet operation of the bearing. The precisely machined components minimize friction and wear, extending the service life of the bearing even in high-load, high-speed applications. The crossed cylindrical roller bearings design significantly reduces the bearing’s cross-section, which is vital for applications with strict spatial constraints, without compromising on performance. This makes them a superior choice compared to traditional bearing arrangements that would require a larger footprint to achieve similar load capacities and rigidity.

Key Applications of RB Crossed Roller Bearings

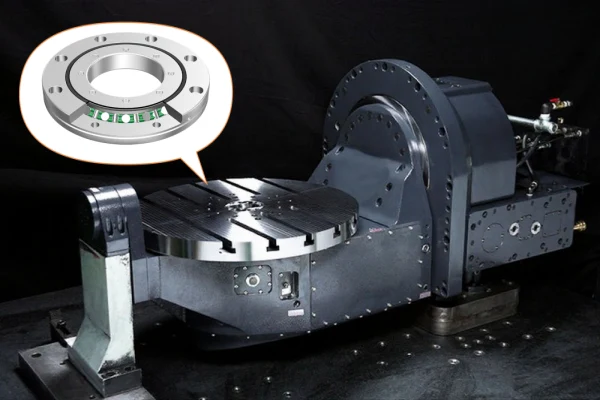

Thanks to their unique structure and high performance characteristics, RB Crossed Roller Bearings are widely used in a variety of high precision bearings applications. One of their most prominent uses is in the rotary table bearings of machine tools. The ability to handle complex loads with exceptional accuracy makes them perfect for indexing tables, which require precise rotational positioning to achieve fine machining tolerances. The compact, high-rigidity design also makes them a popular choice for robot bearings, particularly in the rotating joints and end-effectors of robotic arms.

Beyond these specific examples, RB series bearings are also integral components in thin section bearings applications, precision measuring instruments, and medical devices. Their ability to deliver high rotational accuracy and stiffness in a small footprint is a significant advantage in these fields. By using a single bearing to replace a conventional arrangement of multiple bearings, they simplify machine design, reduce component count, and improve overall system performance.

Comparing RB with Other Crossed Roller Bearing Types

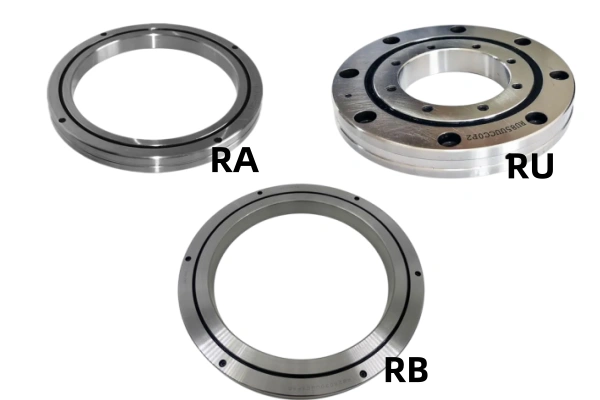

The RB Crossed Roller Bearing is a fundamental model. The key distinction lies in their ring structure. The RB series features a separable outer ring, which is ideal for inner ring rotation applications and easier assembly.

In contrast, the RU series has an integrated inner and outer ring, with mounting holes in both rings. This one-piece design provides extremely high rigidity and makes it a “mount-and-use” solution without needing extra fixing flanges, making it suitable for both inner and outer ring rotation.

Another notable comparison is with the RA Crossed Roller Bearings, which are an ultra-thin version of the RB type. While both have a separable outer ring and a one-piece inner ring, the RA series is designed to be as thin as possible to reduce weight, making it a perfect fit for aerospace bearings and robot joints where weight savings are critical. The RB type, while also compact, prioritizes a balance of rigidity and a slightly more robust design.

FREQUENTLY ASKED QUESTIONS