Home / Product / Roller Bearings / Crossed Roller Bearings / CRBC Crossed Roller Bearings

CRBC Crossed Roller Bearings

CRBC Crossed Roller Bearings are a standard type of crossed roller bearings with a cage design. They are compact, high-rigidity bearings ideal for applications requiring high precision, smooth rotation, and minimal deformation. CRBC bearings are widely used in rotary tables, robots, medical equipment, and optical devices. Compared to other types like thin section bearings or aerospace bearings, CRBC offers a balance of strength, ease of installation, and performance under radial, axial, and moment loads.

Loading...

Total 102 Results

Part Number

Brand

Size

Bore Dia

Outer Dia

Width

R(min)

Shoulder Height Ds(max)

Shoulder Height Dh(min)

Seal Type

Weight

CRB10020

TFL

100 mm x 150 mm x 20 mm

100 mm

150 mm

20 mm

1 mm

113 mm

133 mm

Open

1.45 Kg

CRB10020UU

TFL

100 mm x 150 mm x 20 mm

100 mm

150 mm

20 mm

1 mm

113 mm

133 mm

Double Seal

1.45 Kg

CRBC10020

TFL

100 mm x 150 mm x 20 mm

100 mm

150 mm

20 mm

1 mm

113 mm

133 mm

Open

1.45 Kg

CRBC10020UU

TFL

100 mm x 150 mm x 20 mm

100 mm

150 mm

20 mm

1 mm

113 mm

133 mm

Double Seal

1.45 Kg

CRB11020

TFL

110 mm x 160 mm x 20 mm

110 mm

160 mm

20 mm

1 mm

120 mm

143 mm

Open

1.56 Kg

CRB11020UU

TFL

110 mm x 160 mm x 20 mm

110 mm

160 mm

20 mm

1 mm

120 mm

143 mm

Double Seal

1.56 Kg

CRBC11020

TFL

110 mm x 160 mm x 20 mm

110 mm

160 mm

20 mm

1 mm

120 mm

143 mm

Open

1.56 Kg

CRBC11020UU

TFL

110 mm x 160 mm x 20 mm

110 mm

160 mm

20 mm

1 mm

120 mm

143 mm

Double Seal

1.56 Kg

CRB12025

TFL

120 mm x 180 mm x 25 mm

120 mm

180 mm

25 mm

1.5 mm

133 mm

164 mm

Open

2.62 Kg

CRB12025UU

TFL

120 mm x 180 mm x 25 mm

120 mm

180 mm

25 mm

1.5 mm

133 mm

164 mm

Double Seal

2.62 Kg

CRBC12025

TFL

120 mm x 180 mm x 25 mm

120 mm

180 mm

25 mm

1.5 mm

133 mm

164 mm

Open

2.62 Kg

CRBC12025UU

TFL

120 mm x 180 mm x 25 mm

120 mm

180 mm

25 mm

1.5 mm

133 mm

164 mm

Double Seal

2.62 Kg

CRB13025

TFL

130 mm x 190 mm x 25 mm

130 mm

190 mm

25 mm

1.5 mm

143 mm

174 mm

Open

2.82 Kg

CRB13025UU

TFL

130 mm x 190 mm x 25 mm

130 mm

190 mm

25 mm

1.5 mm

143 mm

174 mm

Double Seal

2.82 Kg

What Makes CRBC Crossed Roller Bearings Unique?

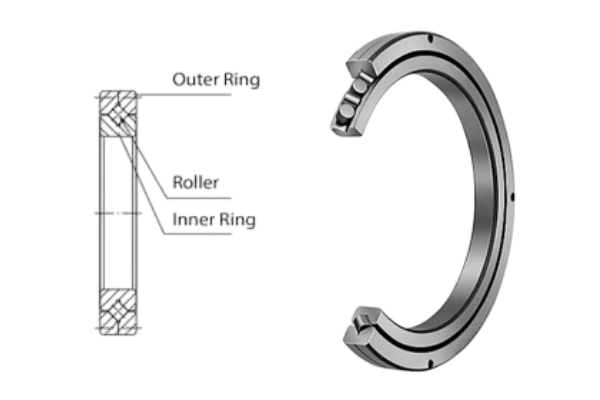

CRBC Crossed Roller Bearings are designed with an integrated inner and outer ring, featuring a cage to maintain roller spacing. This design ensures uniform load distribution and reduces friction. Unlike crossed tapered roller bearings, CRBC bearings do not require preload adjustment, making installation easier and ensuring consistent performance.

Compared to thin section bearings, CRBC bearings offer better rigidity and load capacity, making them more suitable for rotary table bearings and other demanding applications. Their ability to handle radial, axial, and moment loads with minimal deformation makes them a top choice in compact, high-precision systems.

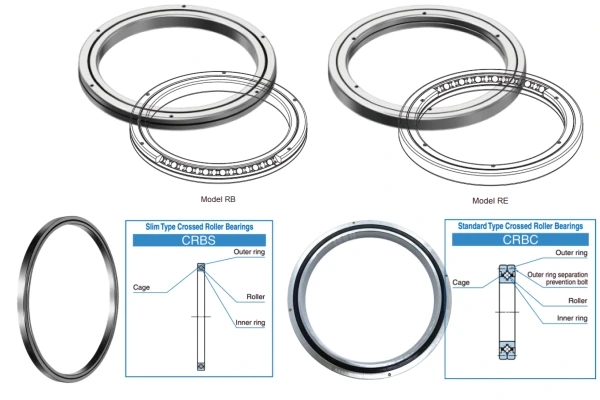

CRBC Crossed Roller Bearings vs. Other Crossed Roller Types

When compared to RB or RE Crossed Roller Bearings, CRBC Crossed Roller Bearings offer easier mounting and higher rotational stability. While RB types require flange fixing or complex support, CRBC simplifies this process due to its integrated mounting-ready structure.

In contrast to CRBS ultra-thin type bearings, CRBC maintains a better balance between rigidity and thickness. This makes CRBC ideal when space is limited but performance cannot be compromised.

Applications of CRBC Crossed Roller Bearings

CRBC Crossed Roller Bearings are widely used in robot bearings, rotary table bearings, and aerospace bearings due to their high rigidity and smooth rotation. Their ability to handle complex loads makes them essential in dynamic environments where precision and space-saving are critical.

They are also applied in semiconductor manufacturing equipment, optical devices, and medical diagnostic tools. Wherever high positioning accuracy and compact structure are required, CRBC delivers reliable performance under demanding conditions.

FREQUENTLY ASKED QUESTIONS

How do I know if CRBC Crossed Roller Bearings are right for my equipment?

If your application requires compact installation, high rigidity, and precision—especially for handling combined loads (like robotic arms, rotary tables, or optical equipment)—CRBC Crossed Roller Bearings are an ideal choice. The integrated structure and mounting holes also simplify your assembly process and reduce time and cost.

Will CRBC Crossed Roller Bearings lose accuracy over time with extended use?

Under proper operating conditions and with correct installation and lubrication, CRBC bearings offer excellent wear resistance and deformation control, maintaining high rotational accuracy over long periods. We recommend regular inspection and timely relubrication to ensure long service life.

Is the installation of CRBC bearings complicated? Do I need a specialist to install them?

CRBC Crossed Roller Bearings are designed for easy installation, with mounting holes and an integrated ring structure that helps reduce assembly errors. While no special tools are required, we recommend having a technician with experience install them to ensure optimal performance.

Are CRBC Crossed Roller Bearings suitable for high-speed or heavy-load environments?

Yes, CRBC bearings can handle axial, radial, and moment loads simultaneously, with high rigidity and load capacity. With proper lubrication and installation, they also perform well under medium to high-speed conditions. For ultra-high-speed applications, a customized solution may be more appropriate.