Home / Product / Ball Bearings / Deep Groove Ball Bearings / Stainless Steel Deep Groove Ball Bearings

Stainless Steel Deep Groove Ball Bearings

The Stainless Steel Deep Groove Ball Bearings can resist corrosion caused by moisture and other media.

Loading...

Total 612 Results

Part Number

Bore Dia

Outer Dia

Width

System of Measurement

Dynamic Radial Load

Static Radial Load

Weight

D/W RW168-2Z

0.25"

0.375"

0.15618"

Inch

48 lbf

20 lbf

0.0006 kg

D/W R188

0.25"

0.5"

0.125"

Inch

139 lbf

50 lbf

0.0015 kg

D/W R188-2RS1

0.25"

0.5"

0.18748"

Inch

139 lbf

50 lbf

0.002 kg

D/W R188-2Z

0.25"

0.5"

0.18748"

Inch

139 lbf

50 lbf

0.0021 kg

D/W R4

0.25"

0.625"

0.19598"

Inch

192 lbf

71 lbf

0.0038 kg

D/W R4 A-2Z

0.25"

0.625"

0.196"

Inch

283 lbf

112 lbf

4.46 g

D/W R4-2RS1

0.25"

0.625"

0.19598"

Inch

192 lbf

71 lbf

0.0042 kg

D/W R4-2Z

0.25"

0.625"

0.19598"

Inch

192 lbf

71 lbf

0.0042 kg

D/W R4A

0.25"

0.75"

0.21882"

Inch

344 lbf

132 lbf

0.0073 kg

D/W R4A-2RS1

0.25"

0.75"

0.28118"

Inch

344 lbf

132 lbf

0.009 kg

D/W R4A-2Z

0.25"

0.75"

0.28118"

Inch

344 lbf

132 lbf

0.0091 kg

D/W R1810

0.31252"

0.5"

0.15618"

Inch

70 lbf

32 lbf

0.0014 kg

D/W R1810-2ZS

0.31252"

0.5"

0.15618"

Inch

70 lbf

32 lbf

0.0015 kg

D/W ER1038

0.375"

0.625"

0.15618"

Inch

110 lbf

49 lbf

0.0024 kg

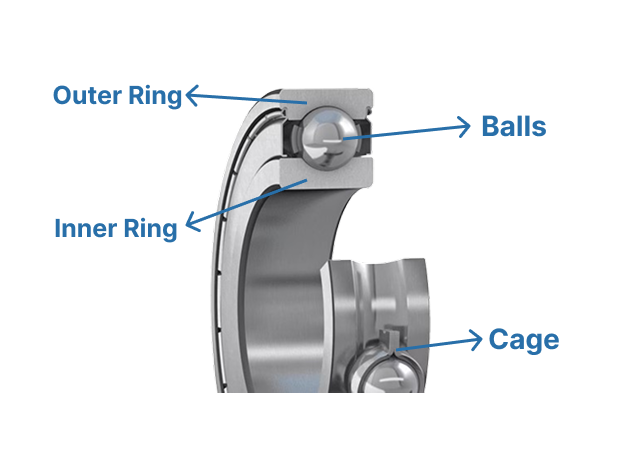

Structural Characteristics of Deep Groove Ball Bearings

Of all ball bearing types, deep groove ball bearings are the most widely used rolling bearings. It has low friction resistance, high rotation speed. They can withstand radial loads or combined loads acting radially and axially at the same time.

Deep groove ball bearings are mainly composed of the following four parts:

- Inner ring and outer ring: Both have continuous deep groove raceways to guide the rolling of the steel balls.

- Steel balls (rolling elements): Round steel balls for ball bearings roll in raceways, reducing friction and transmitting loads through point contact.

- Cage: Usually stamped steel sheets (small ball bearings) or brass solids (large ball bearings), used to evenly separate the steel balls.

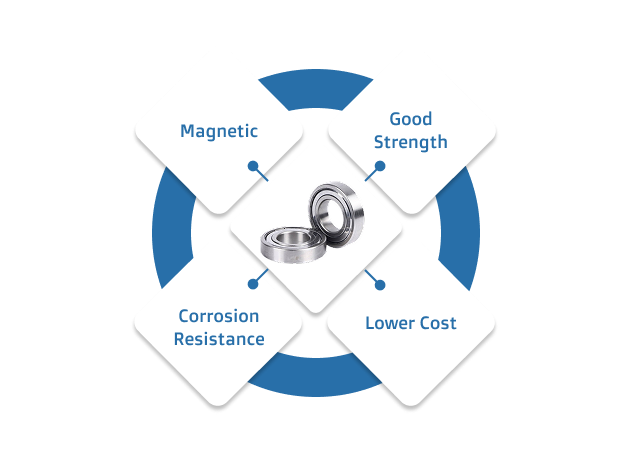

Commonly Stainless Steel Models and Characteristics

304 Stainless Steel: Known for its excellent corrosion resistance, it has good mechanical strength and toughness.

316 Stainless Steel: Molybdenum is added to 304 stainless steel to further enhance corrosion resistance, making it particularly suitable for highly corrosive environments such as marine and chemical industries.

440C Stainless Steel: This is a high-carbon stainless steel with extremely high hardness and excellent wear resistance. Although its corrosion resistance is relatively poor, it can still effectively resist the erosion of many chemicals.

420 Stainless Steel: It performs well in hardness and wear resistance, and its comprehensive performance is between 304 and 440C.

Application of Stainless Steel Deep Groove Ball Bearings

Stainless steel ball bearings have excellent corrosion resistance and good corrosion resistance.By choosing suitable lubricant, dust cover, etc., they can be used under the environment of -60℃~+300℃.

Application scenarios:

- Food processing: Stainless steel bearings are suitable for food processing machinery and can resist chemical corrosion and humid environments that may be encountered during food processing.

- Pharmaceutical machinery: In the pharmaceutical production process, stainless steel bearings can withstand the corrosion of various chemical reagents and ensure the stable operation of the equipment.

- Other corrosive environments: Stainless steel ball bearings perform well in environments such as seawater, salt water, acidic or alkaline solutions.

FREQUENTLY ASKED QUESTIONS

What seal types are available for stainless steel deep groove ball bearings?

There are two types of seals for stainless steel deep groove ball bearings:

- Metal sheild: with the suffix ZZ or 2Z, for example: S6210ZZ.

- Contact rubber seals: with the suffix 2RS or RS, for example: S62082RS, 6202RS bearing

Stainless steel deep groove ball bearings, what information corresponds to the model number?

To learn the bearing letter meaning,we take S6008ZZC3 as an example, S stands for bearing made of stainless steel, 6008 for bearing type,it can also show the bearing dimensions, ZZ for bearing with metal seals on both sides, and C3 for clearance class.

Is the price of stainless steel deep groove ball bearings cheaper than other materials?

Stainless steel bearings are usually more expensive than bearing steel bearings, and their resistance to rust and corrosion is superior to bearing steel.

Where can I buy stainless steel deep groove ball bearings?

TFL bearing offers a wide range of high quality bearings.To purchase ball bearings, please contact us by clicking this link.