Bearings are among the most critical components in industrial machinery, responsible for reducing friction, supporting loads, and enabling smooth rotational or linear motion. Even the highest-quality bearing, however, can fail prematurely if lubrication is inadequate or improperly applied. Bearing lubrication is not just a maintenance task; it is a fundamental factor that directly influences bearing performance, energy efficiency, and service life.

In industrial environments where machines operate under heavy loads, high speeds, and harsh conditions, proper lubrication becomes even more essential. Poor lubrication practices are one of the leading causes of bearing failure worldwide. Understanding lubrication types, application methods, and maintenance best practices is therefore critical to reducing downtime, controlling costs, and improving overall machine reliability.

What Is Bearing Lubrication

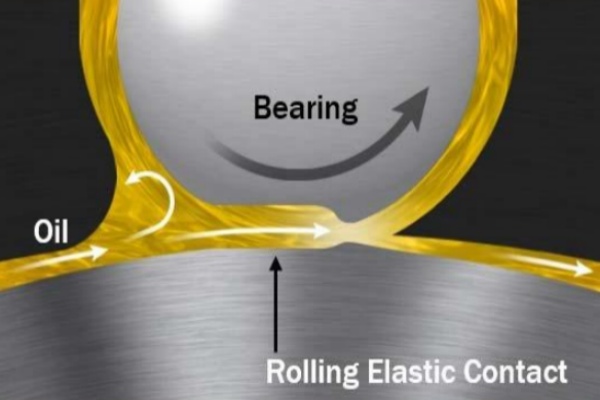

Bearing lubrication refers to the application of a lubricant between rolling elements and raceways to reduce friction and prevent direct metal-to-metal contact. The lubricant forms a protective film that allows smooth motion while minimizing wear and surface damage.

In addition to friction reduction, bearing lubrication performs several other critical functions. It helps dissipate heat generated during operation, protects bearing surfaces from corrosion, and acts as a barrier against contaminants such as dust, moisture, and debris. Without effective lubrication, bearings rapidly degrade, leading to noise, vibration, overheating, and eventual failure.

Why Proper Bearing Lubrication Is Essential

One of the primary purposes of bearing lubrication is to control friction. When lubrication is insufficient, friction increases sharply, causing excessive heat and accelerated wear. This heat can degrade both the lubricant and the bearing material, dramatically shortening service life.

Lubrication also plays a vital role in temperature regulation. Bearings generate heat naturally during operation, particularly in high-speed or high-load applications. A suitable lubricant absorbs and dissipates this heat, preventing thermal damage. Additionally, lubrication helps prevent corrosion by forming a protective layer that shields bearing surfaces from moisture and chemical exposure.

Maximize Reliability: Even the best lubrication cannot fix a flawed bearing. Start with a strong foundation. [Inquire about our heat-treated, durable bearing series] via info@sdtflbearing.com.

Types of Bearing Lubricants

The most commonly used bearing lubricants are grease and oil. Each type serves different operating requirements and offers distinct advantages.

Grease lubrication is widely used due to its simplicity and ability to remain in place. Grease consists of a base oil thickened with a soap or non-soap thickener. It is ideal for moderate-speed applications and for bearings that are difficult to access, as it requires less frequent reapplication.

Oil lubrication is preferred in high-speed, high-temperature, or heavily loaded applications. Oil provides superior cooling and heat dissipation and can be continuously circulated through the bearing. This makes it suitable for large industrial machines, high-speed spindles, and systems requiring precise temperature control.

Selecting the Right Lubricant

Choosing the correct lubricant is one of the most critical decisions in bearing lubrication. Lubricant selection depends on operating speed, load, temperature, and environmental conditions. Bearings operating at high speeds require lower-viscosity lubricants to reduce friction, while heavily loaded bearings often need higher-viscosity lubricants to maintain a protective film.

Environmental factors must also be considered. Bearings exposed to moisture, dust, or chemicals may require lubricants with corrosion inhibitors or enhanced sealing compatibility. Selecting the wrong lubricant can result in poor film formation, lubricant breakdown, and accelerated bearing wear, even if lubrication is applied frequently.

Factory Precision: We manufacture bearings designed to handle extreme loads and speeds, making your lubricant selection easier and more effective. [Get a quote for high-load industrial bearings today].

Bearing Lubrication Methods

There are several methods for applying lubrication, depending on the machinery design and operating conditions. Manual lubrication is common in smaller machines and involves applying grease at regular intervals using grease guns or lubrication ports.

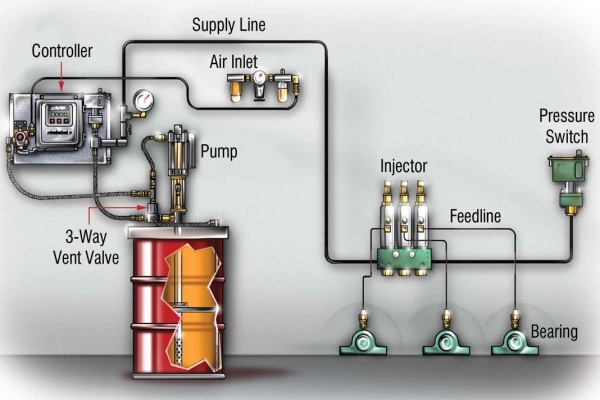

Automatic lubrication systems are widely used in industrial environments to ensure consistent and accurate lubricant delivery. These systems reduce the risk of human error, prevent over- or under-lubrication, and are particularly useful for bearings located in hard-to-reach areas.

Oil lubrication methods include oil bath, oil splash, oil circulation, and oil mist systems. Each technique offers different benefits in terms of cooling efficiency, lubricant control, and contamination management. The choice of method depends on bearing speed, load, and system complexity.

Common Bearing Lubrication Mistakes

One of the most common lubrication mistakes is over-lubrication. Excess lubricant increases internal friction, raises operating temperatures, and can cause seal damage or lubricant leakage. Over-lubrication often leads to overheating and premature failure.

Under-lubrication is equally harmful, resulting in inadequate film formation and increased metal-to-metal contact. Other common mistakes include using the wrong lubricant, mixing incompatible greases, and introducing contaminants during lubrication. These errors significantly reduce bearing life and reliability.

Lubrication Intervals and Maintenance Planning

Establishing correct lubrication intervals is essential for effective bearing maintenance. Intervals depend on bearing size, speed, load, temperature, and environmental exposure. Bearings operating in harsh or high-speed conditions typically require more frequent lubrication.

Condition monitoring techniques such as vibration analysis, temperature monitoring, and lubricant inspection help determine optimal lubrication schedules. Adjusting intervals based on real operating data rather than fixed timelines improves reliability and reduces unnecessary maintenance.

Long-Term Partners: We don’t just sell bearings; we support your maintenance strategy with products built for longevity. [Call +86 15806631151 for a consultation].

Signs of Improper Bearing Lubrication

Several warning signs indicate lubrication problems. Increased noise, excessive vibration, and abnormal temperature rise are common indicators. Discolored, hardened, or contaminated lubricant also signals lubrication failure.

Ignoring these signs can result in rapid bearing damage and unexpected machine downtime. Early detection allows corrective action before catastrophic failure occurs.

Impact of Proper Lubrication on Costs and Reliability

Proper bearing lubrication significantly extends service life, reduces maintenance frequency, and improves energy efficiency. Well-lubricated bearings operate with lower friction, consume less power, and generate less heat.

In industrial operations, these benefits translate into reduced downtime, lower repair costs, and improved productivity. Investing in proper lubrication practices delivers long-term value by reducing the total cost of ownership.

Bearing lubrication is a critical factor in machine reliability and performance. Proper lubrication reduces friction, controls temperature, protects against contamination, and extends bearing life. Understanding lubrication types, application methods, and maintenance best practices helps prevent premature bearing failure and costly downtime.

In demanding industrial environments, effective bearing lubrication is not optional. It is a fundamental requirement for achieving long service life, operational efficiency, and long-term cost control.

Partner with SDTFL Bearings for Peak Performance

We know that proper lubrication is the lifeline of your machinery, but it all starts with installing a high-quality bearing. At SDTFL Bearings, we combine decades of manufacturing expertise with premium materials to provide you with bearings that offer superior reliability and longer service intervals.

Don’t let bearing failure disrupt your operations. Whether you need sealed bearings that require zero maintenance or heavy-duty roller bearings for oil-bath systems, we have the factory-direct solution you need.

Ready to optimize your machinery’s performance?

- [Contact us Today] for a custom quote.

- Email us: info@sdtflbearing.com

- Call/WhatsApp: +86 15806631151

Let us help you drive efficiency and reduce downtime.

Frequently Asked Questions (FAQ) About Bearing Lubrication

What is bearing lubrication, and why is it so important?

Bearing lubrication minimizes friction and wear by separating rolling elements from raceways. It also controls heat, prevents corrosion, and protects against contamination, making it essential for reliable operation.

How often should bearing lubrication be applied?

Lubrication frequency depends on speed, load, temperature, and environment. High-speed or high-temperature applications require more frequent lubrication, while sealed bearings may not require re-lubrication.

What happens if a bearing is over-lubricated?

Over-lubrication increases friction and heat, damages seals, and can cause lubricant leakage. This often leads to premature bearing failure.

Is grease or oil better for bearing lubrication?

Neither is universally better. Grease is suitable for moderate speeds and limited access, while oil is preferred for high-speed or high-temperature applications requiring better cooling.

Can the wrong lubricant cause bearing failure?

Yes. Incorrect viscosity, incompatible additives, or poor temperature resistance can prevent proper film formation and accelerate wear, even with frequent lubrication.

Is it safe to mix different types of grease?

Mixing greases is generally not recommended unless compatibility is confirmed. Incompatible greases can lose lubrication effectiveness and shorten bearing life.

How does contamination affect lubrication?

Contaminants disrupt the lubricant film, causing abrasive wear. Clean application practices and effective sealing are essential to prevent contamination-related failures.

Do sealed bearings require lubrication maintenance?

Sealed bearings are lubricated for life but still require monitoring. Excessive heat or seal damage can shorten their service life.

How does proper lubrication affect energy efficiency?

Proper lubrication reduces friction and power consumption, improving energy efficiency and lowering operating costs.

Can proper lubrication significantly extend bearing service life?

Yes. Correct lubrication selection and application can extend bearing life several times compared to poorly lubricated systems.