SKF INSOCOAT bearings help protect equipment from electrical damage. These bearings feature a special insulating layer on their surfaces. The coating, made from aluminum oxide, blocks current from passing through the bearing. This unique design stops electrical currents from causing wear or failure. Many machines rely on skf insocoat bearings to keep operations safe and reliable.

Key Takeaways

- SKF INSOCOAT bearings have a special ceramic coating that blocks electrical currents to protect machines from damage.

- The thin aluminum oxide layer stops electrical erosion, extending the life of bearings and reducing maintenance needs.

- These bearings fit directly into machines without changes, making installation easy and cost-effective.

- SKF INSOCOAT bearings work well in electric motors, generators, and other equipment exposed to stray electrical currents.

- Using these bearings helps prevent machine breakdowns, lowers repair costs, and improves overall reliability.

SKF INSOCOAT Bearings

What They Are

SKF INSOCOAT bearings stand out from regular bearings because of their special design. These bearings have an electrically insulating coating made from aluminum oxide. Manufacturers apply this coating to the outer or inner ring using a plasma spray process. The layer is very thin, about 0.05 mm, but it is strong and durable. This coating can handle high voltages, up to 1,000 volts, without breaking down.

The insulating layer acts as a barrier, stopping electricity from passing through the bearing. This feature protects the bearing from problems like electrical corrosion and false brinelling, which often damage conventional bearings.

SKF INSOCOAT bearings keep the same size and shape as standard bearings. This means they fit easily into machines without any special adjustments. The coating also gives the bearings high thermal stability, so they work well in tough environments like electric motors and generators. Regular bearings do not have this coating and can get damaged if electricity flows through them.

Main design differences between SKF INSOCOAT bearings and conventional bearings:

- Electrically insulating aluminum oxide coating applied by plasma spray

- Thin, durable layer (about 0.05 mm) resists dielectric breakdown up to 1,000 V

- Prevents electric current flow, protecting against electrical corrosion and false brinelling

- Maintains ISO standard dimensions and tolerances for easy replacement

- High thermal stability and durability for use in electrical equipment

- Conventional bearings lack this protection and are more likely to suffer electrical damage

Key Purpose

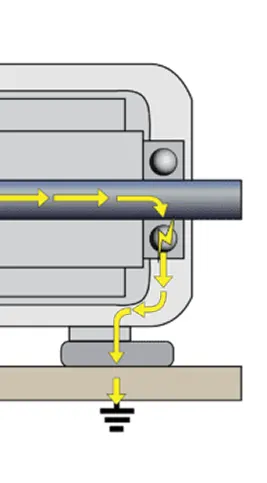

The main purpose of skf insocoat bearings is to protect machinery from electrical damage. In many industrial machines, electrical currents can travel through motor bearings. These currents may cause surface damage like pitting or spalling. Sometimes, they create hot spots on the bearing surface. The heat can also damage the grease inside the bearing, making it less effective.

Skf insocoat bearings solve these problems by using a ceramic coating on the bearing ring. This coating insulates the bearing and blocks the flow of electricity. As a result, the bearing avoids damage from stray currents. This is especially important in machines that use variable frequency drives or run at high speeds, where electrical stress and temperature can rise quickly.

SKF INSOCOAT bearings also improve reliability in electric motors. The special coating keeps stray currents from causing electrical arcing or corrosion. The insulation can resist up to 400 megaohms and handle voltages up to 3,000 volts. A sealant protects the coating from moisture and harsh conditions, so the bearing keeps working well over time. These bearings offer the same mechanical performance as standard bearings, so they can replace regular bearings without extra steps. By stopping electrical damage, they help reduce maintenance costs, prevent downtime, and extend the life of both the bearing and the machine.

How They Work

Insulating Coating

SKF uses a special process to create the insulating layer on INSOCOAT bearings. The company applies a coating made of aluminum oxide to either the inner or outer ring of the bearing. This process uses plasma spraying, which heats the coating material to a very high temperature and sprays it onto the metal surface. The result is a uniform and strong layer that sticks tightly to the bearing ring.

The coating is not just pure ceramic. It contains a mix of stainless steel and ceramics, with carefully controlled pores. This combination gives the coating both strength and the ability to block electricity. The thickness of the coating can reach up to 500 micrometers, but it usually stays thin enough to keep the bearing’s size unchanged. SKF checks the quality of each coating by testing and recording process details. This ensures that every bearing meets strict standards for insulation and durability.

The plasma-sprayed aluminum oxide layer acts as a tough barrier. It protects the bearing from electrical currents and keeps the bearing surface safe from damage.

Electrical Protection

The main job of the insulating coating is to stop electricity from passing through the bearing. When a machine runs, stray electrical currents can try to move through the metal parts. If these currents pass through a regular bearing, they can cause pitting, heat, and even destroy the grease inside. The special coating on SKF INSOCOAT bearings blocks this current flow.

The coating provides high electrical resistance. Most INSOCOAT bearings can handle voltages up to 1,000 volts. Some models, like the 6311M/C3VL0241, can withstand up to 3,000 volts. The newest generation of these bearings can even resist up to 6,000 volts of direct current. This high level of protection works even in tough conditions, such as high humidity or extreme temperatures.

The table below shows how different models compare:

| Bearing Model | Coating Material | Voltage Withstand Level (DC) |

|---|---|---|

| 6219/C3VL0241 SKF | Aluminum oxide | Up to 1,000 V |

| 6311M/C3VL0241 SKF | Aluminum oxide | Up to 3,000 V |

| New generation INSOCOAT | Optimized oxide ceramic | Up to 6,000 V |

The coating’s high resistance and breakdown voltage make it a reliable choice for protecting bearings in electric motors and generators. The insulation also helps prevent grease breakdown and surface damage, which can lead to longer service life and fewer repairs. Compared to other insulation methods, the plasma-sprayed aluminum oxide layer offers a cost-effective and durable solution for modern electrical equipment.

Features & Benefits

Electrical Erosion Protection

SKF INSOCOAT bearings offer strong protection against electrical erosion. The ceramic coating on the outer ring acts as a shield, blocking stray currents that can damage the bearing. This insulation prevents problems like pitting and fluting, which often appear in high-voltage electric motors and inverters. For example, the INSOCOAT 6312M/C3VL0241 bearing is used in electric vehicles to stop electrical erosion in real-world conditions. Non-insulated bearings do not have this protection. They allow electrical currents to pass through, which can create micro craters and damage the lubricant. SKF INSOCOAT bearings break the current path, reducing the risk of early failure and keeping machines running smoothly.

Note: The ceramic coating helps prevent premature bearing failure, especially in demanding applications like electric vehicles and industrial motors.

Service Life

SKF INSOCOAT bearings help extend the service life of machinery. The insulation stops electrical discharge from reaching the bearing surfaces. This reduces wear and keeps the raceways smooth. Machines that use these bearings often run longer without needing repairs. The bearings also protect the lubricant inside, so it lasts longer and keeps the bearing working well. By stopping electrical erosion, SKF INSOCOAT bearings help machines stay reliable and reduce the need for frequent maintenance.

A simple comparison:

| Bearing Type | Resistance to Electrical Erosion | Expected Service Life |

|---|---|---|

| Non-insulated | Low | Shorter |

| SKF INSOCOAT | High | Longer |

Cost-Effectiveness

SKF INSOCOAT bearings provide a cost-effective solution for electrical insulation. They remove the need for extra insulation methods, such as insulating the shaft or housing. This makes installation easier and avoids extra costs. These bearings almost eliminate failures caused by stray currents, which means machines have less downtime and lower maintenance expenses. Even though the initial price may be higher than standard bearings, the savings from fewer repairs and longer machine life lead to a lower total cost of ownership.

- No extra installation steps needed

- Fewer breakdowns and repairs

- Increased uptime and reliability

Tip: Using SKF INSOCOAT bearings can help companies save money over time by reducing maintenance and extending equipment life.

Applications

Electric Motors

Electric motors often face problems from stray electrical currents. These currents can pass through the bearings and cause damage. Many industries use electric motors with variable-frequency drives. These drives can increase the risk of electrical erosion inside the motor. SKF INSOCOAT bearings help solve this problem by blocking the flow of electricity through the bearing. This protection prevents pitting, fluting, and grease breakdown. As a result, electric motors run longer and need less maintenance.

Maintenance engineers have noticed that using these bearings leads to fewer breakdowns and longer service intervals. This means machines stay in operation and production does not stop.

Common industries that use these bearings in electric motors include:

- Manufacturing plants

- HVAC systems

- Water treatment facilities

- Steel mills

Generators

Generators also benefit from insulated bearings. Stray currents in generators can cause electrical arcing, which damages the bearing surfaces. SKF INSOCOAT bearings use a ceramic coating to stop these currents. This coating keeps the rolling elements and raceways safe from electrical erosion. Wind power generators, in particular, face high risks from electrical currents and harsh weather. The insulation in these bearings helps wind turbines and other generators last longer and work more reliably.

A quick look at how these bearings help in generators:

| Benefit | Result |

|---|---|

| Prevents electrical arcing | Less surface damage and longer life |

| Reduces friction | Smoother operation and less heat |

| Handles harsh conditions | Reliable in wind, heat, and humidity |

Other Uses

SKF INSOCOAT bearings are not limited to motors and generators. Many other machines use them to prevent electrical damage and corrosion. Industries such as automotive, aerospace, and construction rely on these bearings for their durability and insulation. Wind turbines, for example, need bearings that resist both electrical currents and harsh environments. Pharmaceutical manufacturing also uses these bearings because they do not need grease, which keeps clean rooms free from contamination.

Tip: These bearings are easy to install and do not require special tools or changes to the machine. This makes them a smart choice for upgrades and repairs.

SKF’s INSOCOAT bearings deliver strong protection against electrical damage in rotating machinery. Their ceramic coating blocks stray currents, helping prevent pitting and early failure. Industry reports show these bearings extend equipment life and improve efficiency in sectors like wind energy and transportation. SKF’s ongoing investment in research and advanced manufacturing keeps these solutions reliable and effective. For companies seeking long-term durability and fewer breakdowns, INSOCOAT bearings offer a proven choice over alternatives such as conductive greases.

TFL also offers alternatives to the SKF INSOCOAT series, including SKF INSOCOAT deep groove ball bearings and SKF INSOCOAT cylindrical roller bearings. If you have any requirements, please feel free to contact us at any time for the latest quotations.

FAQ

What makes SKF INSOCOAT bearings different from standard bearings?

SKF INSOCOAT bearings have a special ceramic coating. This coating blocks electrical currents. Standard bearings do not have this protection. The coating helps prevent electrical damage and extends bearing life.

Can SKF INSOCOAT bearings replace regular bearings directly?

Yes. SKF INSOCOAT bearings match the size and shape of standard bearings. They fit into machines without any changes. No special tools or adjustments are needed for installation.

How long does the insulating coating last?

The ceramic coating on SKF INSOCOAT bearings lasts for many years. It resists wear, moisture, and high temperatures. Regular checks help ensure the coating stays effective.

Where are SKF INSOCOAT bearings most useful?

These bearings work best in electric motors, generators, and wind turbines. They protect against electrical damage in places where stray currents often cause problems.

Do SKF INSOCOAT bearings need special maintenance?

No special maintenance is needed. Regular care, such as checking for wear and keeping the bearing clean, helps them last longer. The insulation does not require extra attention.