A high-speed train moves quickly across the land. Inside the train, the traction motor works in tough conditions. Engineers use traction motor insulated bearings to stop electrical damage. Fast speeds make strong currents in the traction motor. These currents can hurt the traction motor and stop the train. Traction motor insulated bearings keep the traction motor safe and help the train run well. Every train needs these bearings to work well at high speeds. Without them, the traction motor would break down often in a high-speed train.

Key Takeaways

- Insulated bearings keep traction motors safe from bad electrical currents. This helps trains stay safe and last longer. These bearings have special coatings or ceramic parts. These block electricity and stop damage like pitting and corrosion. High-speed trains get hot and carry heavy loads. They also shake a lot. So, bearings must be strong, reliable, and have good lubrication. Insulated bearings help lower maintenance and repair costs. They do this by stopping electrical damage early. Checking traction motor bearings often helps find problems early. This keeps high-speed trains running well.

Traction Motor Insulated Bearings

Definition and Purpose

Traction motor insulated bearings are very important in high-speed trains. These bearings keep the traction motor safe from electrical harm. Engineers make these bearings to stop stray electrical currents. This helps the traction motor work well and last longer.

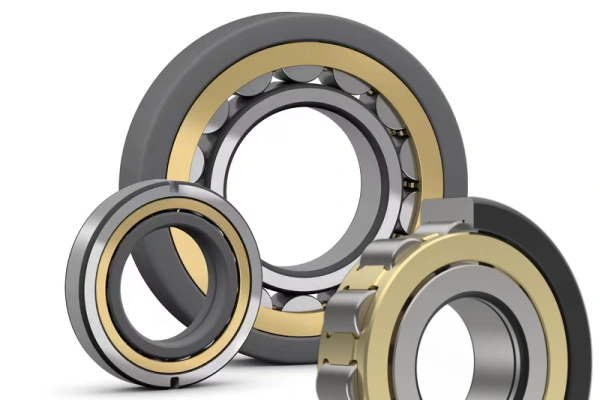

A traction motor uses a cylindrical roller bearing to hold the spinning shaft. High-speed trains have strong electrical currents in the traction motor. These currents can go through the cylindrical roller bearing and cause damage. Traction motor insulated bearings use special coatings or ceramic parts to block these currents. The insulation layer, often made of aluminum oxide, covers the inside or outside ring of the cylindrical roller bearing. This layer makes it harder for electricity to pass and lowers the risk of damage.

Traction motor insulated bearings protect the traction motor. They help the cylindrical roller bearing last longer and need fewer repairs. These bearings fit into the traction motor like normal bearings but give more protection. The design lets the traction motor handle fast speeds and heavy loads safely.

Note: Traction motor insulated bearings are needed in today’s trains. They help the traction motor work well, even when things get tough.

Key Features

Traction motor insulated bearings have many special features that make them different from regular bearings:

- An insulating coating, like aluminum oxide, goes on the inside or outside ring of the cylindrical roller bearing.

- Some traction motor insulated bearings use ceramic rolling parts, such as silicon nitride, for better insulation.

- These bearings stop electrical pitting and corrosion in the traction motor.

- The cylindrical roller bearing design stays the same, so the bearings are easy to change or upgrade.

- Hybrid bearings with ceramic parts lower friction, make less heat, and help grease last longer in the traction motor.

- Sealed and pre-lubricated units are easy to put in and keep the traction motor clean.

- The insulation layer raises electrical resistance and keeps the traction motor safe from strong currents.

- Traction motor insulated bearings work in many places, like electric motors and trains.

- These bearings help the traction motor run longer before it needs fixing.

- The cylindrical roller bearing shape holds heavy loads and fast speeds, which is great for traction motor use.

A traction motor needs the cylindrical roller bearing to keep its moving parts steady. Traction motor insulated bearings make sure the traction motor stays safe from electrical problems. This protection helps the traction motor last longer and work better.

Electrical Currents in Traction Motors

Sources and Risks

High-speed trains need strong power for the traction motor. The traction motor gets electricity from different systems. These systems can be DC, AC, or a mix of both. The table below lists the main ways traction motors get power:

| Electrification System Type | Source of Electrical Current | Voltage Range | Description |

|---|---|---|---|

| DC Electrification System | Three-phase power from grids changed to DC by rectifiers and converters | 600V to 3000V (from overhead lines or third rails) | DC is used for city, suburban, and main train lines; gives high starting power; power comes from third rail or wires above |

| AC Electrification System | High voltage AC from wires above is lowered and changed by transformers and converters | 11kV to 25kV (usually single-phase at 16.7Hz or 50Hz) | AC is used for heavy and main train lines; uses transformers and converters for motors; needs fewer power stations |

| Composite Systems | Mix of AC and DC supply systems | Varies | These systems change AC to DC for DC traction motors; used in some main train lines |

Power conversion systems help the traction motor work right. These systems use PWM converters and inverters. Special parts like Silicon Carbide (SiC) transistors help control high voltages and fast speeds. They make the system work better and last longer. In some trains, each car has its own traction motor. This spreads out the power and keeps parts from wearing out too fast. Sometimes, stray currents show up from things like capacitive coupling, magnetic flux, or changing frequencies. These stray currents can hurt the traction motor and its bearings. Watching and checking these systems helps engineers find problems early.

Impact on Bearings

Stray currents in the traction motor can go through the bearings. This can cause many kinds of electrical damage. Pitting, fluting, micro-cratering, spalling, and frosting can happen from electric arcs. When current goes through the bearing, it makes tiny sparks. These sparks melt and harden the bearing surface. This makes small holes and weak spots. Over time, these problems make the traction motor shake and get noisy. Fluting makes lines on the bearing that show arc damage. Spalling and pitting make the traction motor not last as long. When bearings fail, these marks are often found. Checking the bearings often helps stop sudden breakdowns. Trains with motors in each car do better with regular checks. Engineers use these checks to help the traction motor last longer and work better. Without good protection, stray currents can cause lots of repairs and stops. The traction motor needs insulated bearings to stop these currents and keep it safe.

Note: Checking traction motor bearings often is very important. This helps keep trains safe and stops expensive breakdowns.

High-Speed Railway Demands

Operational Challenges

A high-speed train has to deal with many hard things. The traction motor works very fast every day. This makes a lot of heat inside the traction motor. The cylindrical roller bearing feels this heat and must keep working well. High-speed trains also carry heavy loads. The traction motor holds up the train’s weight and handles strong forces. Fast movement makes these forces even stronger. Vibration is a big problem too. When the train moves, the traction motor and cylindrical roller bearing shake a lot. If the shaking is not stopped, it can hurt the traction motor.

The train also goes through places where it gets very hot or cold. The traction motor and cylindrical roller bearing must work in all kinds of weather. Lubricants inside the traction motor break down faster when the train goes fast. This makes it harder for the cylindrical roller bearing to stay smooth. The train needs special materials in the traction motor to help with these problems. The cylindrical roller bearing must fight wear and keep the traction motor working.

Bearings in high-speed trains face heat, shaking, heavy loads, and fast lubricant breakdown. These things make the traction motor and cylindrical roller bearing work harder than in normal trains.

| Challenge/Feature | Description |

|---|---|

| Load Handling Capability | The cylindrical roller bearing in the traction motor must hold up heavy loads from the high-speed train. |

| Axial and Radial Stability | The traction motor needs the cylindrical roller bearing to keep the train wheels straight. |

| Durability and Reliability | The traction motor uses strong materials in the cylindrical roller bearing so it lasts longer. |

| High-Speed Performance | The cylindrical roller bearing must work well at high speeds in the traction motor. |

| Maintenance Requirements | The traction motor and cylindrical roller bearing need easy checks to keep the high-speed train running. |

| Contamination Protection | The cylindrical roller bearing in the traction motor must stay clean to stop damage. |

Bearing Requirements

The traction motor in a high-speed train needs special bearings. The cylindrical roller bearing must handle lots of shaking and twisting. The traction motor spins very fast, so the cylindrical roller bearing must keep up. The train puts a lot of force on the traction motor, so the cylindrical roller bearing must hold both sideways and up-and-down loads. The traction motor also faces stray electrical currents. The cylindrical roller bearing needs insulation to stop these currents from causing harm.

A high-speed train uses special lubrication in the traction motor. This helps the cylindrical roller bearing last longer. The traction motor needs seals to keep dirt out of the cylindrical roller bearing. The train relies on the traction motor to work in all weather. The cylindrical roller bearing must stay strong in hot and cold. The traction motor needs the cylindrical roller bearing to be exact and tough. The train depends on the traction motor and cylindrical roller bearing for safe trips.

- The traction motor in a high-speed train must fight shaking and twisting.

- The cylindrical roller bearing must work at fast speeds in the traction motor.

- The train needs the traction motor to handle heavy loads.

- The cylindrical roller bearing must have insulation for the traction motor.

- The traction motor uses special lubrication for the cylindrical roller bearing.

- The train needs the traction motor and cylindrical roller bearing to last a long time.

- The traction motor must keep the cylindrical roller bearing clean and safe.

- The train depends on the traction motor and cylindrical roller bearing for safety.

- The traction motor and cylindrical roller bearing must work in all weather.

- The train needs the traction motor and cylindrical roller bearing to be strong and reliable.

Checking the traction motor and cylindrical roller bearing often helps the train avoid problems. Early checks find issues before they stop the train. The train stays safe when the traction motor and cylindrical roller bearing get regular checks.

How Insulated Bearings Work

Insulating Materials

Engineers pick special insulating materials to keep the traction motor safe. These materials stop electricity from going through the bearing. This helps protect the traction motor from harm. The most common materials are ceramic coatings and ceramic rolling elements. Each one has special features that help in tough places. The table below lists the main types of insulating materials and what they do:

| Insulating Material Type | Description | Properties and Characteristics | Application Notes |

|---|---|---|---|

| Ceramic Coatings (Aluminum Oxide) | Put on the inside or outside of bearing rings by spraying, thickness is 50-200 μm | Stops electricity well, works even when it’s wet, can handle up to 1000 V and some up to 3000 V DC | Used a lot on bearing rings for insulation; codes are VL0241, VL0246 (outside), VL2071, VL2076 (inside) |

| Ceramic Rolling Elements | Rolling parts made from ceramic material | Stops current very well, costs more than coatings | Not used as much because of price; gives great insulation by using ceramic rolling parts |

| Bearing Types | Deep groove ball bearings, cylindrical roller bearings, tapered roller bearings, thrust roller bearings | Same size and shape as normal bearings, but with extra insulation | Good for traction motors that need strong insulated bearings |

New insulating materials have made traction motors work better. Today’s insulated bearings use sprayed layers that can handle up to 3000V DC. Silicon nitride hybrid ceramic bearings are now used in new energy vehicles and traction motors. These materials fight wear and help the traction motor run smoothly, even when it’s hot or there are strong magnetic fields.

Electrical Isolation Mechanism

The electrical isolation in insulated bearings is very important. It stops current from hurting the traction motor. Engineers put coatings like aluminum oxide, silicon nitride, or zirconium oxide on bearing surfaces. These coatings act like walls that block electricity from moving through the bearing. The insulation must be strong in many ways to last a long time.

- Insulating materials break the path for electricity in the traction motor, so current cannot go through the bearing.

- This helps the traction motor because it stops damage from electricity.

- The insulation acts like a switch that turns off the flow, so current cannot pass through the bearing.

Electrical isolation in insulated bearings keeps away currents that cause pitting and fluting. When bearings fail, engineers often find damage from stray currents. Using insulated bearings lowers the chance of breakdowns and helps the traction motor last longer. Studies of modern traction motors show these methods help keep trains safe and working well.

Tip: Check traction motor bearings often to find insulation problems early. This keeps the traction motor working its best.

Benefits Over Standard Bearings

Safety and Reliability

High-speed trains need traction motors to be safe and reliable. Insulated bearings work better than standard bearings in these trains. Standard bearings let stray currents pass through. This can hurt the traction motor. Insulated bearings stop these currents. They protect the traction motor from damage.

- Insulated bearings stop electrical discharge machining pitting, electrolytic corrosion, and fusion damage. These problems can make bearings fail early in high-speed traction motors.

- Insulated bearings block harmful currents. This helps the traction motor last longer and lowers the chance of sudden breakdowns.

- Insulated bearings keep working well even at high speeds and power.

- Standard bearings do not have this protection. They can fail from electrical erosion and put the train at risk.

The table below lists common ways standard bearings fail and how insulated bearings help:

| Failure ModeDescriptionHow Insulated Bearings Help | ||

|---|---|---|

| Electrical Erosion (Arcing) | Current goes through the bearing and causes pitting and lubricant breakdown. This leads to failure. | Insulated bearings block current and stop this damage. |

| Inadequate Lubrication | Thin or dirty lubricant hurts the bearing surface. | Insulated bearings do not fix this; good lubrication is still needed. |

| Damage from Vibration | Vibration can hurt bearings if the rotor shaft is loose. | Insulated bearings do not fix this; careful handling is needed. |

| Improper Installation | Wrong mounting or misalignment overloads and damages the bearing. | Insulated bearings do not fix this; correct installation is needed. |

| Insufficient Bearing Load | Too little load smears and damages the bearing. | Insulated bearings do not fix this; enough load is needed. |

Insulated bearings give important protection from electrical damage. This is the main reason bearings fail in high-speed traction motors. This protection makes the rail system safer and more reliable.

Railway operators have seen many good things after using insulated bearings:

- The chance of electrical damage drops a lot, so high-speed trains are safer.

- Trains need less maintenance because grease lasts longer and bearings are better designed.

- Less friction and wear at the start make trains run better.

- Smaller bearings mean traction motors can be shorter or more powerful.

- Sensorized bearings help check bearing health, so repairs can be planned and reliability goes up.

Maintenance and Service Life

High-speed trains travel far and need traction motors that last long. Insulated bearings help by lowering how often maintenance is needed. Standard bearings in traction motors often break early from electrical damage. Insulated bearings stop this, so the traction motor runs longer without repairs.

- Insulated traction motor bearings protect from current damage. This can make bearings last much longer.

- With insulated bearings, maintenance and re-greasing can go over one million kilometers.

- Sometimes, re-greasing is not needed between overhauls. This makes maintenance easier for high-speed trains.

- Using insulated bearings with oil lubrication and better designs means fewer stops for maintenance and lower costs.

Railway operators save money after switching to insulated bearings. The bearing unit design lets trains go longer between maintenance, saves space, and is easy to put in. These changes mean less maintenance and lower costs for the traction motor’s life. Insulated bearings also keep lubricants safe from electrical damage. This helps the traction motor run smoothly and safely.

Operators can use monitoring systems to check insulated bearing health. Watching bearing condition helps find problems early and keeps high-speed trains safe.

Insulated bearings help high-speed traction motors meet strict safety and reliability rules. There is no special certification just for insulated bearings. But top makers follow rail industry certifications like AAR and ISO/TS22163. These show a promise to quality and safety in every traction motor.

A high-speed train needs insulated bearings to keep the traction motor safe. Experts say these bearings stop electrical damage. They help the train run longer and need less fixing. Train operators see fewer problems and spend less money. New bearing technology uses AI and better materials. This will help high-speed trains work even better. When picking bearings, experts look at load, speed, and smart features. For the best choice, ask TFL Bearings for help with traction motors in high-speed trains.

Every high-speed train will need strong and smart bearings. These bearings help the train move safely and work well.

FAQ

What is the main purpose of insulated bearings in traction motors?

Insulated bearings keep electricity from going through the bearing. This keeps the traction motor safe from getting hurt. The insulation helps the motor last longer and work well at fast speeds.

How do insulated bearings differ from standard bearings?

Insulated bearings have a special layer or ceramic parts. These parts stop electricity from passing through. Standard bearings do not have this kind of protection. Insulated bearings help stop electrical damage in traction motors.

Can insulated bearings reduce maintenance costs?

Yes, they can. Insulated bearings lower the chance of electrical damage. This means there are fewer repairs and less time when trains cannot run. Operators save money and trains can run longer.

What types of insulation materials do engineers use?

Engineers use ceramic coatings like aluminum oxide or ceramic rolling parts. These materials block electricity very well. They help keep the traction motor safe from stray currents.

Are insulated bearings suitable for all high-speed rail environments?

Insulated bearings work well in many kinds of rail places. They can handle fast speeds, heavy loads, and changes in temperature. Operators pick them because they work well in hard conditions.