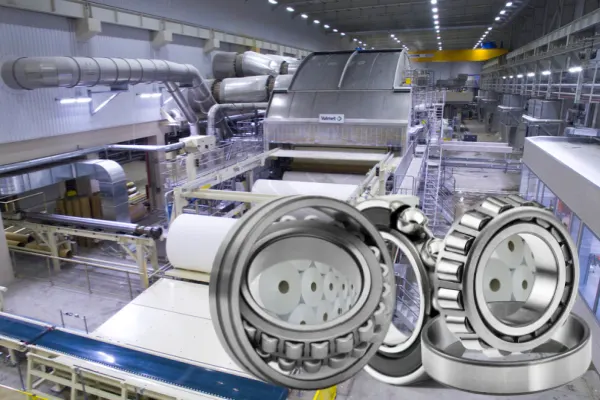

You deal with hard problems in the paper industry each day. Heavy loads, misalignment, heat, and moisture all hurt your machines. Contamination makes it even worse. Roller Bearings for Paper Mills give you strength and dependability. Only the right bearings can handle these tough jobs. Downtime costs money in the paper industry. You need solutions that last a long time.

Key Takeaways

- Pick the right roller bearing type for each paper mill area. This helps handle heavy loads, heat, moisture, and misalignment well. Use self-aligning bearings like spherical roller bearings. These help lower wear and stop downtime from shaft misalignment. Keep bearings safe from dirt by using good seals. Do regular checks and use the right lubrication to make bearings last longer. Follow the right steps for putting in and caring for bearings. This means fitting them right, keeping work areas clean, and checking lubrication often. Doing this helps stop bearings from failing early. Think about using smart bearings and custom solutions. These can find problems early and help machines work better.

Paper Mill Challenges

High Loads

Paper mills have to deal with heavy loads every day. Big rollers and drums push down hard on the bearings. This pressure can make machines wear out faster. Data shows roller bearings in the wet section last 50,000 to 100,000 hours. Bearings in the dry section or on dryer rolls can last up to 250,000 hours. The difference depends on where the bearing is and how much weight it holds. Heavy loads can bend or damage parts, especially if there is not enough grease. New bearing materials and better grease help bearings last longer. But you still need to watch the load to stop early breakdowns.

| Paper Mill Section | Recommended Operating Life (hours) |

|---|---|

| Wet Section | 50,000 to 100,000 |

| Dry Section | 150,000 to 250,000 |

| Guide Rolls (Roller) | 150,000 to 250,000 |

| Dryer Rolls (Roller) | 150,000 to 250,000 |

| M.G. Cylinders (Roller) | 150,000 to 250,000 |

| Refiners (Roller) | 50,000 to 100,000 |

| Calenders (Roller) | 50,000 to 100,000 |

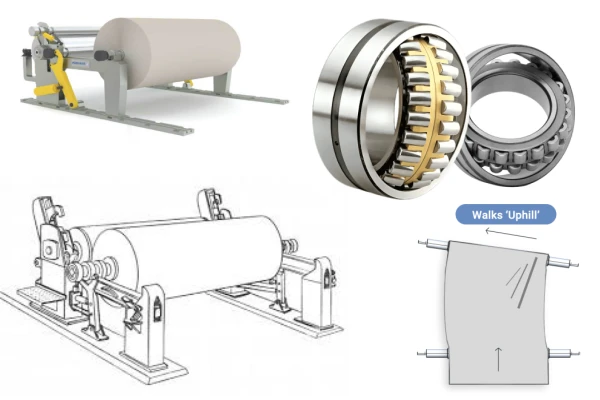

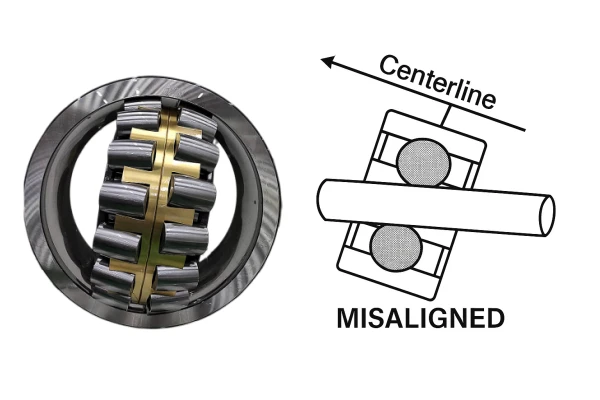

Misalignment

Misalignment is common in paper mills. Shafts get longer, machines shake, and mistakes happen when putting things together. Bearings in these machines must handle angles from 0.3° to 1°. If you do not fix misalignment, you get more shaking, noise, and faster wear. Self-aligning bearings help machines run well, even when things move or settle.

Heat and Moisture

Paper mills have both heat and moisture in different places. The dryer section can get as hot as 125°C (257°F). The wet section is cooler but has lots of water. High heat can make oil go bad and bearings get bigger. Water can cause rust and break down grease. You need bearings that can handle both heat and water, especially in the wet section, to keep things working right.

Contamination

There are many contaminants in paper mills. Water, dust, and chemicals can get into bearings and cause trouble. Water can ruin grease and cause rust and sludge. Dust from machines and fillers can wear down surfaces and make you fix things more often. Leaks make you use more oil and spend more money. Good seals and regular checks help keep bearings safe from these problems.

Tip: Checking your machines often and using good seals can stop most contamination problems in your conveyor systems and other important equipment.

Roller Bearings for Paper Mills

Picking roller bearings for paper mills is not easy. Each part of the mill needs a special bearing. The right bearing helps machines last longer. It also stops expensive downtime. Here are the main types and where they work best.

Spherical Roller Bearings

Spherical roller bearings are very important in paper mills. You see them in the wet end, press, and drying sections. These bearings hold up heavy radial and axial loads. Their barrel shape lets them adjust if the shaft is not straight. This happens when machines move or are put together wrong. The self-aligning feature keeps rollers working well, even if things shift.

You use spherical roller bearings in the wet end because they fight water and steam. In the press section, they handle water and heavy loads. In drying sections, they stand up to heat and steam. Special coatings and seals keep out rust and dirt. These bearings also take in shock and vibration. This helps stop early breakdowns.

Note: Spherical roller bearings can handle up to 3° misalignment. This makes them great for tough paper mill jobs.

When you pick spherical roller bearings, think about load, speed, and temperature. You also need strong seals. Their tough design means less downtime and better energy use in your mill.

Cylindrical Roller Bearings

Cylindrical roller bearings are important in the press and some drying sections. They hold heavy radial loads and work at high speeds. Their design helps with good alignment. This is needed for smooth and accurate movement. These bearings do not wear out fast. They keep working in wet, dusty, or hot places.

Cylindrical roller bearings have tight fits. This lowers friction and helps machines run faster. Some have self-aligning outer rings. This stops uneven wear and lets them grow with heat. This means fewer problems and longer life in the press section.

- Hold heavy radial loads

- Work at high speeds

- Stand up to heat and moisture

- Need less maintenance

Tapered Roller Bearings

Tapered roller bearings are strong for high-load spots. You use them where machines get both radial and thrust loads. This is in some press and drying sections. Their tapered shape gives true rolling motion. This stops skidding and early wear.

These bearings hold more load than ball bearings. They are almost as strong as spherical roller bearings. You can put them in easily. They adjust to misalignment and heat changes. This makes them good for hard paper mill jobs.

- Hold both radial and axial loads

- Stop skidding and wear

- Easy to put in and adjust

Deep Groove Ball Bearings

Deep groove ball bearings are best for fast parts of the mill. You find them in drying sections where machines run fast. They give smooth and quiet work. These bearings have low friction. This saves energy and cuts down on shaking.

They hold both radial and axial loads. But they do not handle misalignment as well as others. Still, their simple design and low upkeep make them a top pick for nonstop work. You get less downtime and longer life, even in hot and wet places.

| Bearing Type | Load Handling | Misalignment Tolerance | Speed Capability | Shock Resistance | Typical Applications |

|---|---|---|---|---|---|

| Spherical Roller Bearing | Radial & axial (heavy) | High (up to 3°) | Moderate | High | Wet end, press, drying sections |

| Cylindrical Roller Bearing | Radial (heavy) | Low | High | Moderate | Press, drying sections |

| Tapered Roller Bearing | Radial & axial (heavy) | Moderate | Moderate | High | Press, drying sections |

| Deep Groove Ball Bearing | Radial & axial (moderate) | Low | High | Moderate | Drying sections (high-speed) |

Tip: Always pick the right bearing for each part of the mill. This gives you the best work and longest life for your roller bearings in paper mills.

Bearing Features in the Paper Industry

Load Capacity

Bearings in the paper industry must hold heavy loads. Machines push down hard on every bearing. Spherical roller bearings can take both radial and axial loads. But, only about 25% of the dynamic load rating is used in real life. This is normal for the paper industry. Never let the load reach the static rating when running machines.

- Always use a safety factor of 1.5 to 2 for tough jobs.

- ANSI/ABMA standards 9 and 11 help with load rating math.

- L10 bearing life tells you how long a bearing may last.

- Bigger bearings give extra safety for heavy loads and misalignment.

Remember: Using bigger bearings than needed helps stop sudden failures and keeps machines working longer.

Self-Alignment

Misalignment happens a lot in the paper industry. Long shafts, heat, and moving machines make parts shift. Self-aligning bearings, like spherical roller bearings, fix this problem. They let the bearing move if the shaft or housing is not straight. This lowers stress and wear inside the bearing. Bearings last longer and break down less.

- Self-alignment fixes angles from bent shafts or bad mounting.

- Less stress means less wear and fewer repairs.

- You save time and money on fixing machines.

Self-aligning bearings help you have less downtime and spend less in your paper mill.

Sealing and Lubrication

Moisture and dirt are big problems in the paper industry. Good seals and grease keep bearings safe. High-performance greases, like calcium sulfonate complex, protect wet-end bearings from water and rust. For dry-end bearings, use grease that works in high heat. Automated systems put grease in at the right time. This cuts mistakes and helps bearings last longer.

- Sealed bearings and labyrinth seals block pulp, water, and dirt.

- Non-contact labyrinth isolators, like Inpro/Seal PMR, give lasting protection in wet and dry areas.

- These isolators stop dirt and keep grease inside, even when machines stop.

- Adding flingers or shields to seals helps block water.

- Checking vents and drains often helps you find leaks early.

Tip: Tools like vibration checks and thermal cameras help you find problems before they cause breakdowns.

Durability

Bearings must last in the tough paper industry. Strong materials, smart design, and good care make them durable. Special coatings stop rust and wear. Separable parts and E1 designs make it easy to check and change parts. Bigger bearings and better seals give more protection.

| Feature | Benefit in the Paper Industry |

|---|---|

| Special coatings | Stop rust and help bearings last longer |

| Separable components | Make checking and fixing easier |

| E1 design | Spread loads better and lower stress |

| Oversized bearings | Handle heavy loads and misalignment better |

Durable bearings mean fewer stops and more steady work in your paper mill.

Advanced Technologies

Smart Bearings

Smart bearings help your paper mill work better. These bearings have sensors inside them. The sensors watch for wear, vibration, and heat. You can see problems before machines break. Vibration checks help you find trouble early. If vibration is high between 2,000 and 3,000 Hz, the bearing needs more grease. Ultrasound checks also tell you if there is too much or too little grease.

Augmented reality tools help your team fix things faster. With smart glasses or phones, workers see repair tips and sensor data right at the machine. This makes fixing things safer and easier. Wireless sensors and cloud systems help you plan repairs and stop surprises.

| Sensor Type | Function | Predictive Maintenance Benefit |

|---|---|---|

| DLT.W | Wear sensor for linear systems | Early detection of liner wear |

| DLW.W | Measures wear in linear bearings | Signals when liner replacement is needed |

| PRT.W | Measures abrasion in slewing ring bearings | Predictable replacement of sliding elements |

| isense plain bearing | Integrated wear measurement | Continuous condition assessment for planning |

Smart bearings let you fix problems before machines stop. This saves you time and money.

Material Innovations

Bearings must last through heat, water, and heavy loads. New materials help bearings work better. Special coatings protect against rust and wear. Some bearings use strong steel or ceramics. These can handle heat and chemicals. These materials keep bearings strong in hard places. You get longer life and fewer breakdowns.

- Special coatings stop rust and lower friction.

- Strong steel and ceramics handle heat and chemicals.

- New materials mean less fixing and more working time.

Custom Solutions

Every paper mill has its own problems. Custom bearings fit your machines best. Companies make these bearings with special materials, seals, and grease for your needs. Some mills use spherical roller bearings with extra grease and lifting holes in busy spots. This can cut downtime by 30%. In other cases, custom bearings in the dryer section lower repairs by 40%. You get longer bearing life and better work.

Custom bearings help you fix hard problems and keep your mill running well.

Selection and Maintenance

Bearing Selection

You need to pick the right bearing for each part of your paper mill. First, look at how much weight, speed, and heat are in each area. Spherical roller bearings are good for heavy loads and when things are not lined up right. Cylindrical roller bearings are best for places that need to move fast. Tapered roller bearings can handle both side and straight-on forces. Deep groove ball bearings work well where things move fast but do not carry much weight. Always check what the maker says about the bearing and use extra safety for hard jobs. If your mill is different, you might need a custom bearing.

Installation Tips

Putting in bearings the right way helps them last longer. Many problems happen because of mistakes when putting them in. Here are some common mistakes and how to stop them:

1. Incorrect Shaft Fit: Do not let the bearing fit too loosely. Use special tools to make sure it fits right.

2. Overheating Bearings: Never use too much heat. Use special heaters or put them in cold.

3. Inaccurate Locking Mechanisms: Tighten lock nuts and plates by hand.

4. Misalignment: Use self-aligning bearings and check with the right tools.

5. Unsafe Installation: Do not hit bearings with hammers or use heavy tools. Use safe tools that one person can handle.

6. Contamination: Keep everything clean so dust and water do not get in.

7. Improper Force Application: Only push on the bearing rings, not the rolling parts.

Tip: Keeping things clean and using the right tools helps bearings last longer.

Maintenance Practices

Doing regular checks helps you stop big problems before they start. Smart maintenance uses sensors, oil checks, and heat cameras to find trouble early. You should use special tools to check for wear or if the bearing needs more grease. Good grease and making sure things line up right help bearings work better. Most mills check suction roll bearings once a year and often change them then. Change grease lines every year so they do not break.

| Maintenance Aspect | Recommended Frequency/Practice |

|---|---|

| Suction Roll Bearing Inspection | Check once a year; many mills change the bearing during this check. |

| Lubrication | Do regular checks; add grease through lines during big repairs. |

| Lube Line Replacement | Change every year to stop problems. |

| Condition Monitoring | Use special tools to check often. |

Smart maintenance can help your mill work better and break down less. Checking often and using smart tools helps you fix things before they stop working.

Roller bearings help you solve big problems in the paper industry. When you pick the right bearing and take care of it, your machines break down less. Your equipment runs better and lasts longer.

- Many paper mills say they need to fix machines 40% less after using better bearings. They also have 30% less time when machines are stopped.

- Experts say you should pick bearings carefully and control moisture. This helps your machines stay strong and work well.

You can save more than $1.75 million in ten years if you use high-performance bearings in the paper industry.

We help you follow tough industry rules and give you solutions you can trust for the paper industry. Contact TFL Bearings for expert help and results that work.

FAQ

What type of roller bearing works best in wet sections of a paper mill?

You should pick spherical roller bearings for wet sections. These bearings can handle water and steam. They also carry heavy loads. Their self-aligning shape helps them last longer. This makes them good for tough, wet places.

How often should you check bearing lubrication in a paper mill?

Check the lubrication at least once every month. Automated systems help keep grease at the right level. Regular checks stop early wear. This keeps your machines working well.

Can you use standard bearings in high-temperature areas?

Do not use standard bearings where it gets very hot. Pick bearings made with heat-resistant materials. Use high-temperature grease too. These choices protect bearings from damage. They also help bearings last longer.

What is the main cause of bearing failure in paper mills?

Most bearing failures happen because of contamination. Water, dust, and chemicals get inside bearings. This breaks down the grease. Good seals and regular checks help stop this problem.

🛠️ Tip: Always keep your work area clean when you work with bearings. Clean tools and hands help stop contamination.