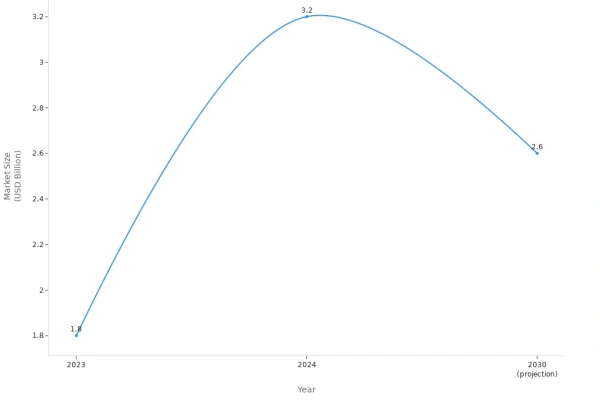

A cross roller bearing has rollers shaped like cylinders. The rollers are set at right angles in a V-shaped groove. This design makes the bearing very strong. It can hold both side and end loads. The structure lets it move smoothly and with great accuracy. This is why it is good for machines that need to be exact. The market for cross roller bearings has grown each year, as you can see below:

Key features include:

- Full line contact gives it more strength

- Small size fits in tight spaces

- Very stiff and turns with high accuracy

These features make a cross roller bearing a great choice. It is best for jobs that need both strength and accuracy.

Key Takeaways

- Cross roller bearings have rollers that are set at right angles. They can hold heavy loads from many directions with high accuracy.

- Their small design fits into tight spaces. They give strong support and smooth, exact movement for machines like robots and medical devices.

- The crossed roller pattern spreads weight out evenly. This makes these bearings stiffer and stronger than ball bearings of the same size.

- Good installation, regular oiling, and keeping them clean help cross roller bearings last longer. They also help the bearings work quietly without noise or shaking.

- Picking the right bearing depends on how much load you need to hold, the size, accuracy, and where it will be used. This helps your machine work its best.

Cross Roller Bearing Basics

What Is a Cross Roller Bearing

A cross roller bearing is a special kind of bearing. It uses rollers shaped like cylinders, not balls. The rollers are set in a crisscross pattern. They sit at right angles to each other. This setup lets the bearing hold weight from many sides. Crossed roller bearings can handle side, end, and twisting loads at once. Most other bearings cannot do this.

Crossed roller bearings are small and fit in tight spots. Their design makes them very stiff and accurate. Machines that need to move exactly often use these bearings. Robots, medical tools, and measuring devices all use them. These bearings help machines move smoothly and stay steady.

Tip: Crossed roller bearings are best when you need both strength and accuracy.

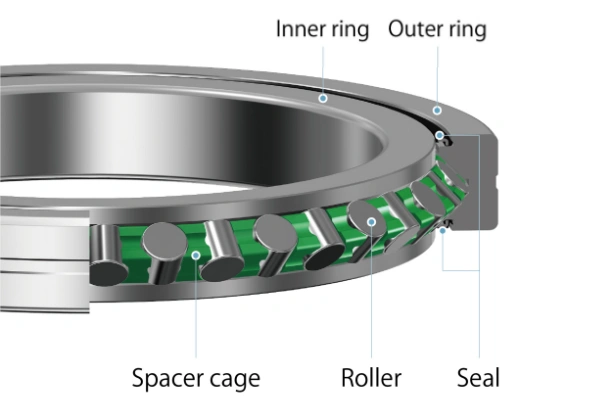

Key Components

Each cross roller bearing has a few main parts. Every part helps the bearing work well. The table below lists the main parts and what they do:

| Component | Function |

|---|---|

| Inner Ring | Has a V-shaped groove to guide rollers; holds rollers in a cross pattern. |

| Outer Ring | Has a V-shaped groove to guide rollers; works with inner ring to keep rollers in place. |

| Cylindrical Rollers | Set crosswise at right angles; help the bearing hold weight from many sides. |

| Spacer Retainers | Keep rollers apart and lower friction; help the bearing turn smoothly. |

| Seals | Keep dirt out and oil in; help the bearing last longer. |

The inner ring and outer ring both have V-shaped grooves. These grooves guide the rollers and keep them in place. The cylindrical rollers go between the rings. They cross each other at right angles. This setup lets the bearing hold heavy loads from any side.

Spacer retainers go between the rollers. They keep the rollers apart and lower friction. This helps the bearing turn without problems. Seals cover the outside of the bearing. They keep out dirt and help keep oil inside.

Crossed roller bearings use this smart setup for high accuracy and stiffness. The way the rollers sit in V-shaped grooves helps the bearing turn smoothly and hold tricky loads. This is why crossed roller bearings are great for machines that need to be very exact.

How Crossed Roller Bearings Work

Roller Arrangement

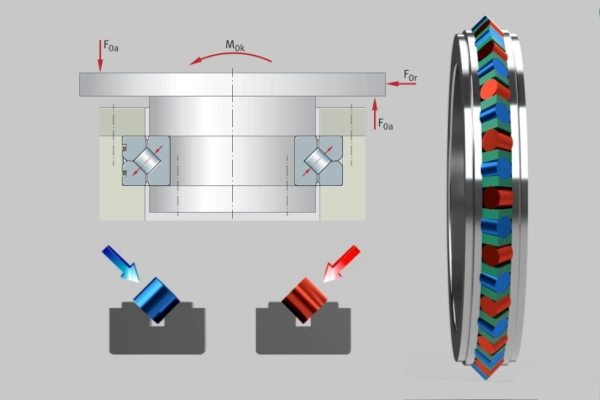

Crossed roller bearings have a special way to arrange their rollers. Each cylindrical roller sits at a right angle to the next one. The rollers cross each other and fill the space between the rings. They do not sit in straight rows like in ball bearings. Instead, they make a grid shape. This helps the bearing take force from many directions.

The crossed pattern spreads the load over more space. Each roller touches the rings along a line, not just one spot. This line contact gives the bearing more strength and makes it stiffer. Ball bearings use balls that touch the rings at only one spot. That means they cannot hold as much weight. Tapered roller bearings have rollers in one direction. They need careful setup to handle different loads. Crossed roller bearings do not have this problem because their rollers are at right angles.

Note: The crossed pattern lets the bearing hold radial, axial, and moment loads all at once. This makes crossed roller bearings a great choice for machines that need to be strong and accurate.

Load Support

Crossed roller bearings can hold many kinds of loads at the same time. The crossed rollers help the bearing take side, end, and twisting forces. The rollers move on smooth surfaces inside the rings. This rolling lowers friction and helps the bearing move easily, even with heavy loads.

The shape and place of the rollers are important for load support. The crossed rollers spread the force over a wide area. This makes the bearing very stiff and able to hold more weight than ball bearings of the same size. Ball bearings use point contact, so they cannot hold as much and may bend under heavy loads. Needle roller bearings can hold two to eight times more load than ball bearings. This is because they have long rollers and line contact.

Here is a quick comparison:

| Bearing Type | Roller/Ball Arrangement | Load Support | Typical Load Capacity |

|---|---|---|---|

| Crossed Roller Bearing | Cylindrical rollers crossed | Radial, axial, moment | Very high |

| Ball Bearing | Balls in parallel rows | Mostly radial | Lower |

| Tapered Roller Bearing | Tapered rollers, one direction | Radial and axial | High, needs careful setup |

Crossed roller bearings use their special roller pattern and line contact to hold heavy loads from any direction. The design also keeps the bearing stiff and accurate. This is important for machines that need to move in a very exact way.

Tip: Crossed roller bearings are best for robots, medical devices, and measuring tools where you need both high load support and accuracy.

Crossed Roller Bearings Features

High Accuracy and Stiffness

Crossed roller bearings are known for being very accurate and stiff. They use cylindrical rollers that cross each other at right angles. This makes the rollers touch more of the surface. It helps spread out the weight and keeps the bearing steady. The bearing does not move around much when it is working. Stiffness means the bearing does not bend easily. This is important for machines that must move in a very exact way. Preload is a small force added when putting the bearing together. It takes away extra space inside the bearing. Preload helps stop shaking and keeps the bearing working well. Factories set preload by moving the rings or using springs. Picking the right preload is important. Too much preload can make the bearing hot and wear out. Too little preload can make it less accurate.

A table below shows ISO and DIN standards. These rules help make sure the bearings are high quality and very exact:

| ISO/DIN Standard | Application to Cross Roller Bearings |

|---|---|

| ISO dimension series 18 | Sets main sizes and ensures compatibility. |

| DIN 616 | Defines small section heights for compact designs. |

| DIN 620-2, 620-3 | Sets dimensional and running tolerances for precision classes P6 and P5. |

| ISO 492 | Defines precision grades (P5, P4, P2) for high-precision applications. |

Load Capacity

Crossed roller bearings can hold a lot of weight. This is because the rollers touch the raceway in a line, not just one spot. The line contact spreads out the force. This lets the bearing hold more weight than ball bearings. Ball bearings only touch at one point, so they are not as strong. The table below shows how crossed roller bearings and angular contact ball bearings are different:

| Feature | Crossed Roller Bearings | Angular Contact Ball Bearings |

|---|---|---|

| Rolling Element | Cylindrical rollers in a cross pattern | Steel balls |

| Contact Type | Line contact | Point contact |

| Load Capacity | Higher; one ring equals two angular contact ball bearings | Lower |

| Rigidity (Stiffness) | 3-4 times greater | Lower |

| Application Suitability | High load and rigidity needs | Lighter loads, higher speed |

Because they can hold so much weight, crossed roller bearings are great for robots and machine tools. They are also good for other machines that need to be strong and very exact.

Compact Design

Crossed roller bearings are small but strong. They fit into tight spaces and still hold heavy loads. The rollers cross each other in one bearing. This means one bearing can do the work of two. Spacers between the rollers stop them from rubbing together. This helps the bearing turn smoothly. Many crossed roller bearings have thin rings. Thin rings save space and make the machine lighter. This also makes it cheaper to build the shaft and other parts. Because they are small and strong, these bearings are perfect for robots and medical devices. They are also good for other machines where there is not much room.

Tip: Crossed roller bearings are small, strong, and very exact. This makes them a great choice for high-tech machines and places where space is tight.

Bearing Cage Types and Issues

Metal vs. Plastic Cages

Cross roller bearings have two main cage types: metal and plastic. Plastic cages are usually nylon or resin. Each type has good and bad points.

- Nylon (Resin) Cages:

- These cages are light and bend easily. This helps make the bearing lighter.

- They make less friction and noise. This is good for quiet machines.

- Rollers can be closer together. This can let the bearing hold up to 250% more weight.

- They are easier and cheaper to make.

- They do not work well in high heat or with strong chemicals.

- They are not as strong or tough as metal cages.

Metal (Steel) Cages:

- These cages can take more heat, heavy loads, and rough places.

- They are stronger and last longer.

- They are heavier and can be louder when working.

- Their shape means you cannot fit as many rollers inside.

Tip: Nylon cages are best for machines that need to be quiet, light, and cheap. Metal cages are better for hot, heavy, or harsh places.

Cage Creep

Cage creep is when the cage moves out of its spot. This often happens if the cage does not fit tightly in the bearing. Other reasons are not enough oil, putting it together wrong, or dirt getting inside. Hard hits or things stuck inside can also hurt the cage and cause creep.

- Common causes of cage creep:

- Cage does not fit tight with the rings

- Not enough oil or grease

- Parts are not lined up or put together wrong

- Dust or hard bits get inside

To stop cage creep, make sure the cage fits right. Use enough oil or grease. Keep the bearing clean.

Noise and Vibration

Noise and shaking in cross roller bearings mean something is wrong. The main reasons are parts not lined up or not enough oil. If the bearing is not straight, the weight is not spread out right. This makes more friction and shaking. Not enough oil or dirty grease also makes more friction. This causes more noise and heat.

Main causes:

- Parts not lined up or put together wrong

- Not enough or dirty oil or grease

- Loose bolts or weak parts

| Problem | Cause | Solution |

|---|---|---|

| Abnormal noise | Add grease, line up parts, tighten bolts | |

| Vibration | Uneven weight, dirty grease | Clean bearing, use good grease |

Check your bearings often. Put them together the right way. Use clean oil or grease to keep them quiet and smooth.

Crossed Roller Slide and Practical Use

Mounting and Travel

It is important to install a crossed roller slide the right way. This helps it move smoothly and stay accurate. Here are the steps you should follow:

- Clean all surfaces before you start. Make sure there is no dirt.

- Use bolts or screws to hold the slide in place. Use a torque wrench so you do not make it too tight or loose.

- Put grease or oil on the rollers and raceways. Check the lubricant often and add more if needed.

- Cover the slide to keep out dust and water. You can use covers or bellows for this.

- Do not put too much weight on the slide. Always look at the manufacturer’s guide for the right amount.

- Check the slide often for damage or if it is not straight. Fix any problems fast to keep it working well.

Travel length means how far the slide can move. Crossed roller slides come in many sizes for different jobs. The table below shows some common travel lengths:

| Product Type | Travel Length Range |

|---|---|

| Crossed Roller Rail Sets | 0.4 inches to almost 12 inches |

| Micrometer Positioning Stages | 0.25 inches to 2.0 inches |

| Lead Screw Driven Stages | Up to 12 inches |

| Custom Rail Lengths | Up to 2 meters (~78.7 inches) |

Most of the time, the rail assembly needs to be about twice as long as the distance you want to move. This lets the rails move in opposite ways. It makes the slide move quietly and smoothly, but it also limits how far it can go.

Lifespan and Maintenance

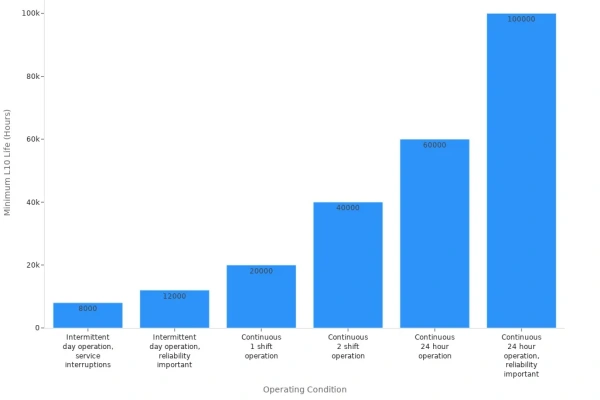

Cross roller bearings can last a long time if you take care of them. The chart below shows how long they can last in different situations:

Here are some tips to help your bearing last longer:

- Use good grease or oil, like lithium soap grease or the right oils.

- Pick the best type and amount of lubricant for your bearing. Think about the size, where it is used, and how fast it moves.

- Lubricate the bearing as often as the maker says. If it is dirty or wet, check it more often.

- If you cannot add more grease, do not use the bearing for more than three years, especially if it gets hot.

- Make sure the seals are good. They keep dirt out and oil in.

- Keep the temperature in the safe range.

- Do not let the bearing go faster than its speed limit.

Crossed roller slides are used in many places. People use them in robots, machine tools, medical machines, and chip-making machines. These jobs need the slide to be very exact, strong, and small. When you pick a bearing, think about the weight, speed, how exact it must be, and how you will take care of it. Choose the right bearing for your job to get the best results.

Cross roller bearings have many good points for small, exact machines. The crossed roller design lets them hold heavy loads from any side. Spacers between the rollers help lower friction. This makes the bearing move easily and smoothly. Their thin shape lets them fit into small spaces. This helps make robots and medical tools smaller. They are made with strong materials and built very carefully. This helps them last a long time and stay accurate.

Because of these things, cross roller bearings are very important for robots, machine tools, and medical devices. If you need help picking the right one, you can ask us at TFL Bearings.

FAQ

What makes a cross roller bearing different from a ball bearing?

A cross roller bearing uses rollers set at right angles, while a ball bearing uses balls. The cross pattern lets it support loads from many directions. Ball bearings mostly handle radial loads.

What types of machines use cross roller bearings?

Robots, medical devices, and machine tools often use cross roller bearings. These machines need high accuracy, strength, and compact size. The bearing helps them move smoothly and stay stable.

What is cage creep in cross roller bearings?

Cage creep happens when the cage moves out of place. This can occur if the cage does not fit tightly or if there is not enough lubrication. Regular checks help prevent this problem.

What kind of maintenance do cross roller bearings need?

Cross roller bearings need regular cleaning and lubrication. Users should check for dirt, damage, or low grease. Proper care helps the bearing last longer and work smoothly.

What should users consider when choosing a cross roller bearing?

Users should look at load capacity, size, accuracy, and the working environment. They should also check if the bearing fits the machine and if it meets the job’s needs.