If you need a bearing OEM replacement without damaging your equipment, you can do so safely by verifying each bearing code. Ensure the technical specifications match precisely. Pay close attention to OEM part numbers and confirm their compatibility. Cross-brand bearing OEM replacement is effective when you understand every code and fit. Utilize the proper tools and reference charts to guarantee your bearing performs optimally.

Key Takeaways

- Always look at the full bearing code and specs before you replace it. This helps make sure the new bearing fits and works like the old one. Use cross-reference charts with care to find bearings from other brands. Check the size, features, and quality before you buy. Handle and put in bearings gently with the right tools. Use clean grease and line up the bearing right to stop damage and help it last longer. Think about where the bearing will be used, like if it is hot, dirty, or has a heavy load. Pick the right seals, materials, and grease for the job. Pick trusted suppliers like TFL Bearings for good quality, fast shipping, and expert help. This keeps your machines working well.

Bearing OEM Replacement Basics

What Is Bearing OEM Replacement

You might need bearing oem replacement when your equipment stops working well. In factories and car making, this means taking out a broken bearing and putting in a new one. The new bearing must match the old one’s details. You have to check the bearing code and technical information. This makes sure the new bearing works just like the old one.

The main reasons for bearing oem replacement are:

- Not enough or wrong lubrication causes most bearing failures. This can happen if you use the wrong oil or if dirt gets in.

- Picking the wrong bearing size or type causes some failures. This can make the bearing break early.

- Putting the bearing in the wrong way can also cause problems. It can make the bearing not line up right.

- Sometimes, things like too much weight, heat, or shaking can break the bearing.

- Rarely, the bearing has a material problem or was made wrong.

You should always pick a replacement with the same oem part number. This helps your equipment last longer and work better.

Why Choose Cross Brand Replacement

You might look at cross brand replacement if the original bearing is hard to get or costs too much. In car making and other jobs, cross brand bearings can save money and give more choices. But you need to check how well it works, if it fits, and what warranty it has.

Tip: Always check the specs and if it fits before picking a cross brand bearing. Even small changes can make a big difference.

Here is a simple table to compare oem and cross-brand bearings:

| Aspect | OEM Bearings | Cross-Brand Bearings |

|---|---|---|

| Fit | Fits just like the original | Might not fit exactly |

| Quality | Very good, meets oem rules | Quality is not always the same |

| Warranty | Has a warranty from maker | May have little or no warranty |

| Performance | Works like the original | Might not work the same |

| Price | Costs more | Usually costs less |

| Availability | Sold by special dealers | Easier to find |

Cross brand bearings can cost less, but they might not last as long. In factories and car making, safety and working well are very important. Always use charts and data to make sure your new bearing is right.

Step-by-Step Replacement Process

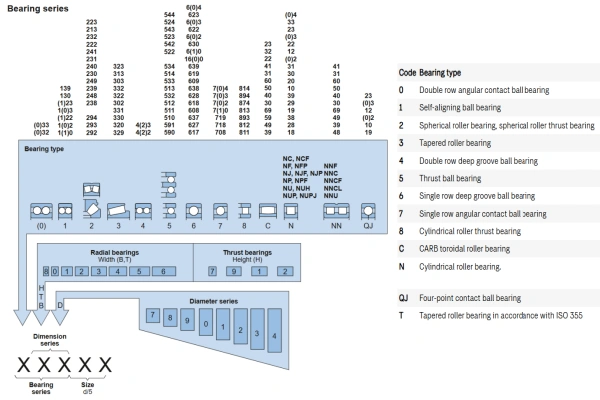

Identify Original Bearing Codes

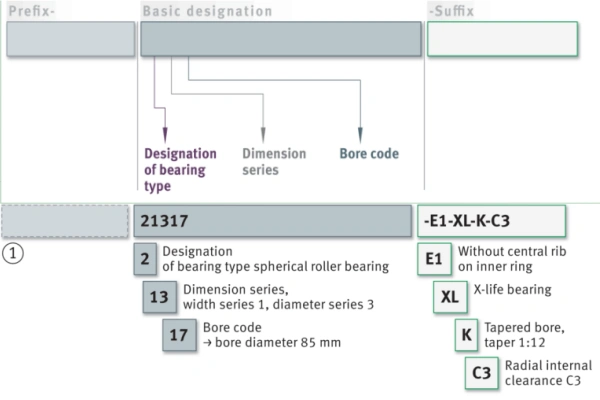

First, you need to find the original bearing codes. Each bearing has a special code. This code tells you its type, size, and features. You can see this code on the bearing or in the manual. Write down the whole code with all letters and numbers. These extra parts show things like cage material or seal type.

If you use needle roller bearings or precision crossed roller bearings, check every part of the code. Even a small change can affect how it fits or works. For example, a suffix can mean a special seal or a new design inside. Always check the code again before you go to the next step.

Tip: Take a clear photo of the old bearing and its code. This helps you avoid mistakes during replacement.

Use Cross-Reference Charts

Once you have the code, use a cross reference chart. This chart helps you find bearings from other brands. You can match the original to brands like SKF, NSK, TIMKEN, and FAG. Companies like GMN Bearing USA and NHBB have these tools. They cover most standard bearings, including needle roller bearings and precision crossed roller bearings.

A cross reference chart makes it easy to see which bearing fits. For common types, like miniature or instrument ball bearings, these charts show direct matches. Here is a table that shows how a cross reference chart helps you compare part numbers:

| Original Brand | Part Number | Equivalent Brand | Equivalent Part Number |

|---|---|---|---|

| SKF | 6205 | NSK | 6205 |

| TIMKEN | 6205-2RS | FAG | 6205.2RSR |

| INA | NK12/16 | NTN | NK12/16R |

Remember, a cross reference chart works well for most standard bearings. But for special or new needle roller bearings or precision crossed roller bearings, it may not be exact. Always talk to an engineer or expert before you decide. This makes sure your replacement will work right and meet the standards.

Check Compatibility Factors

Before you put in the new bearing, check all the important details. This is very important for needle roller bearings and precision crossed roller bearings. Small changes can make a big difference. Look at these points:

- Make sure the size and specs match exactly. Model, size, and accuracy must be the same.

- Check the inside structure, like the shape and number of rolling parts. For needle roller bearings, the length and width of the needles matter.

- Compare what the bearing is made of. Different materials change how much weight it can hold and how long it lasts.

- Think about where the bearing will work. Look at load, heat, wetness, dirt, and rust. These things affect how the bearing works.

- Check how much weight it can hold and how fast it can spin. Some bearings are made differently and this changes these limits.

- Make sure the lubrication system matches. The type and amount of grease must fit the new bearing.

- Look at the sealing system. Good seals keep out dirt and hold in grease. This is very important for needle roller bearings and precision crossed roller bearings.

Note: Good lubrication and sealing help lower friction, stop dirt, and make the bearing last longer.

Follow these steps for safe installation:

- Gently put the bearing into place with a small gap. Tap it lightly, do not hit it hard.

- Use induction heating for the inner sleeve if needed. Keep the heat below 120°C.

- If the bearing does not fit, check for bent parts or wrong size.

- Add the right amount of clean grease.

- Replace or fix any broken seals or parts.

- Check the fit and setup after you finish.

- Watch the lubrication after you install it and add grease if needed.

- Test the bearing to make sure it works right.

- Do not use heavy hammers or tools that can break the bearing.

- Adjust preload carefully to keep it working well and lasting long.

- Follow the maker’s instructions for putting it in.

- Set up regular checks, like changing grease and cleaning seals.

- Tighten bolts in steps and across from each other to fix any misalignment.

If you follow these steps, your new bearing will work well. This is true for standard, needle roller, or precision crossed roller bearings. Using a cross reference chart and checking all details helps you avoid mistakes and keeps your equipment working.

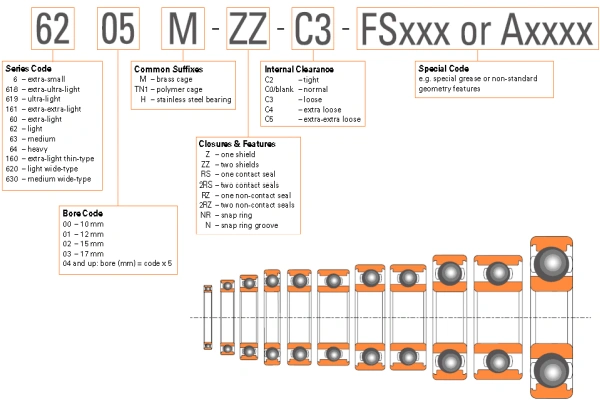

SKF Bearing Code Explanation

Basic, Prefix, and Suffix Codes

When you look at an SKF bearing, you see a code printed on the side. This code tells you important details about the bearing. You can break down the code into three main parts: the basic code, prefix, and suffix. Each part gives you different information.

Here is a simple table to help you understand what each part means:

| Code Component | Meaning / Specification |

|---|---|

| Bearing Series | First digit(s) show the bearing type. For example, ‘6’ means single-row deep groove ball bearing. ‘7’ means angular contact ball bearing. |

| Bearing Size | The next two digits show the bore diameter in millimeters. For example, ’07’ means a 35mm bore. |

| Suffix Letters | These letters show extra features. ‘N’ means a snap ring groove. ‘Z’ or ‘ZZ’ means metal shields. ‘RS’ or ‘2RS’ means rubber seals. |

Tip: Always check the full code, including suffixes, to make sure you select the right bearing for your equipment.

You can use this code to match bearings across brands. This helps you find the right replacement quickly and avoid mistakes.

Key Design Features

SKF designs bearings with features that help you in tough industrial settings. You get better wear resistance and longer life, even when dirt or dust is present. For example, SKF’s self-healing VU091 bearings last much longer in dirty environments. They resist wear seven times better than standard bearings and can last 2.6 times longer under heavy use.

SKF focuses on strong materials and smart engineering. The seals adapt to misalignment and tough conditions. Flexible elastomers in the seals keep out dirt and hold in grease. This means your bearing keeps working, even if the shaft moves a little or the environment changes.

You also save energy with SKF rolling bearings. These bearings cut down on friction, so your machines use less power. In some cases, you can save up to 18 kW per machine. Less friction means less heat and less need for oil, which keeps your equipment cleaner and more efficient.

SKF offers many bearing types for different needs. You can pick spherical roller bearings for heavy loads or deep groove ball bearings for high speeds. Advanced sealing and lubrication systems help you get the most out of each bearing. These design choices help you reduce downtime, lower maintenance costs, and keep your equipment running smoothly.

NSK Bearing Code Explanation

Prefix and Suffix Meanings

When you look at an NSK bearing code, you see more than just a part number. Each code uses a system that tells you the bearing’s type, series, and bore size. You find prefixes and suffixes in these codes. These extra letters and numbers give you important details about the bearing’s features.

Prefixes in NSK codes show you the bearing type or special design. For example, “HR” means a high-load capacity bearing. “BL” stands for a full-complement ball bearing. You need to check the manufacturer’s catalog because prefixes can change between brands.

Suffixes tell you about the bearing’s special features. You see these at the end of the code. Here are some common NSK suffixes and what they mean:

- ZZ: Metal shields on both sides

- 2RS or DDU: Rubber seals on both sides

- C3: Greater than normal internal clearance

- NR: Snap ring groove on the outer ring

- K: Tapered bore

- P5, P6: Precision grades

These suffixes help you pick the right bearing for your job. They show you if the bearing has extra seals, special clearances, or higher precision. You should always read the full code, not just the base number. This helps you avoid mistakes and match the bearing to your equipment.

Note: Suffixes and prefixes are not the same for every brand. Always check the NSK catalog for the exact meaning.

Special Designations

NSK uses special designations to highlight unique features or advanced designs. You might see codes like “EM” for a brass cage or “ET” for a reinforced steel cage. Some bearings use “CM” to show they are made for electric motors. Others use “V” to show a non-contact seal.

You also find designations for high-temperature use, such as “X28” for bearings that work up to 200°C. If you see “DB,” “DF,” or “DT,” these show how you can pair bearings together for different load directions.

Here is a quick table to help you understand some special NSK designations:

Designation | Meaning |

|---|---|

| EM | Brass cage |

| ET | Reinforced steel cage |

| CM | Electric motor clearance |

| V | Non-contact seal |

| X28 | High-temperature (200°C) |

| DB/DF/DT | Mounting arrangement options |

You should always check these designations before you choose a replacement. This ensures the bearing will fit your needs and work well in your application.

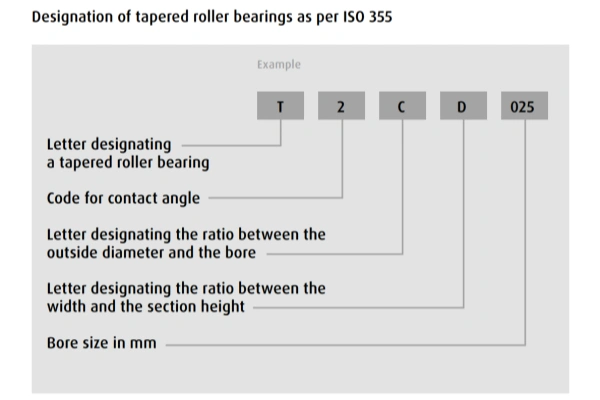

TIMKEN Bearing Code Explanation

Prefix and Suffix Details

A TIMKEN bearing code uses letters and numbers together. Each part of the code gives you key facts about the bearing. The prefix shows the bearing type or a special feature. The suffix tells you about the design, material, or how it works.

These code parts help you pick the right bearing for your machine. Here are some common suffixes and what they mean:

- ZZ: Metal shields on both sides. These keep out dust.

- 2RS or DDU: Rubber seals on both sides. They protect from dirt and water.

- C3: More space inside the bearing. This helps with heat or high speed.

- NR: Snap ring groove. This makes it easier to install.

- K: Tapered bore. It fits special shafts.

- P5, P6: Precision grades. These show higher accuracy.

You can also see codes for heat treatment, cage types, and clearance groups. S0 to S4 show the highest temperature the bearing can take. Cage codes like TA or TB tell you the cage material and how it guides the rollers. Clearance groups from C0 to C5 show the space inside the bearing.

Here is a table to help you understand the main code parts:

| Code Element | Meaning | Explanation |

|---|---|---|

| Prefixes | Bearing variations or parts | Show changes like seals or snap ring grooves |

| Suffixes | Design details | Include material, heat treatment, cage type, clearance, and special features |

| Bearing Type Code | Shows bearing type | For example, ‘3’ means tapered roller bearing |

| Suffix Details | Technical and use features | Show contact angle, clearance, cage, heat treatment, and more |

Note: Always check both the prefix and suffix. This helps you get the right bearing for your job.

Application Notes

You must match the bearing code to your machine. The code tells you if the bearing can handle high speed, heavy loads, or tough places. A bearing with C3 clearance works better in hot or fast machines. If you see ZZ or 2RS, the bearing has extra protection from dust or water.

Heat treatment codes like S1 or S2 show how hot the bearing can get. Special suffixes like KDA or K30 tell you about split rings or tapered bores. These help with special setups. Cage codes like TA or TB show if the cage is brass, steel, or another material. This changes how the bearing handles speed and weight.

Always read the full code before picking a replacement. This helps you avoid mistakes and keeps your machine working well. If you are not sure, check the maker’s chart or ask an expert. The right code means better work and longer bearing life.

FAG Bearing Code Explanation

Structure and Suffixes

When you look at a FAG bearing code, you see a clear pattern. The code has three main parts: prefixes, a basic code, and suffixes. Each part tells you something about the bearing.

The prefix comes first. It shows if the bearing has a special setup, like a thrust race or no separable ring. The basic code is in the middle. This part tells you the bearing’s type, how it is built, and its size. After that, you see suffixes. These show special features, like changes inside, size, sealing, or cage type.

Here is a table to help you see how the code works:

| Code Type | Position in Code | Meaning / Description | Examples |

|---|---|---|---|

| Prefix Codes | Before basic code | Special parts or configurations | GS, K, R |

| Basic Code | Core of the code | Bearing type, structure, and size | 7205, 6207, NJ2312 |

| Suffix Codes | After basic code | Special features or modifications | A, K, K30, RSR, F, K1-K11 |

Suffixes can mean different things. Some show changes inside (A, B, C, D, E). Others show size (K, K30, N, NR), sealing (RSR, ZR, 2ZR), cage type (F, FA, FB), or paired bearings (K1-K11). This system helps you pick the right bearing for your job.

Tip: Always check the whole code, including all suffixes, to make sure you get the right FAG bearing.

Special Features

FAG bearings have many special features. You can find these by looking at the suffixes and prefixes in the code. These features help you pick a bearing for high speed, better sealing, or higher heat.

Here are some common suffixes and what they mean:

- .2RS: Two rubber seals for extra protection

- .T5: ABEC-5 tolerance for high precision

- -C3: More space inside for higher speed or heat

- .M: Brass retainer, roller guided

- .S1: Can handle high heat up to 390°F

- .22: Two metal shields for dust

- .P4, .P5, .P6: ISO tolerance classes for precision

- .RS, .RSR: One rubber seal for dirt and water

- .K, .K30: Tapered bore for special shafts

- .UL: Universal mounting and preload

You also see prefixes like NU, NJ, NN, and NUP. These show different cylindrical roller bearing designs. Other prefixes, like A, B, C, and E, show angular contact ball bearings with different angles or designs.

Here is a quick table for special features:

| Code/Suffix/Prefix | Special Feature Description |

|---|---|

| .2RS | Two rubber seals |

| .T5 | ABEC-5 tolerance class |

| -C3 | More space inside (AFBMA standard) |

| .M | Brass retainer |

| .S1 | High temperature use |

| .22 | Two metal shields |

| .P4, .P5, .P6 | ISO tolerance classes |

| .RS, .RSR | One rubber seal |

| .K, .K30 | Tapered bore |

| .UL | Universal mounting and preload |

These codes help you find a FAG bearing that fits your needs. This system helps you avoid mistakes and keeps your equipment working well.

INA Bearing Code Supplement

Common Supplement Codes

When you look at INA bearing codes, you see extra letters or numbers after the main part. These are supplement codes. They tell you about special features or changes in the bearing. You need to know these codes to pick the right replacement.

Here are some common INA supplement codes you will find:

| Code | Meaning |

|---|---|

| P | One side has a seal |

| PP | Both sides have seals |

| RS | One side has a rubber seal |

| 2RS | Both sides have rubber seals |

| TN | Plastic cage inside |

| V | Bearing is sealed |

| X | Size or shape changed for standards |

| Z | One side has a metal shield |

| 2Z | Both sides have metal shields |

| ZW | Double row needle roller and cage set |

Tip: Always check these codes before you order a replacement. Even a small change, like a seal or cage type, can affect how the bearing works in your machine.

Special Structures

INA bearings often use special structures to meet different needs. You can spot these by looking at the supplement codes. Some bearings have extra seals for better protection. Others use special cages or materials for higher speed or longer life.

You might see codes like D for split needle roller and cage assemblies. AS means the outer ring has a lubrication hole. SM01 shows the bearing uses a special grease for high or low temperatures. If you see ZW, the bearing has two rows of rollers for more strength.

- P6, P5, P4: These codes show higher precision. You need these for machines that must run very smoothly.

- C2, C3, C4: These codes tell you about the space inside the bearing. More space helps with heat or speed.

Note: Always match the supplement codes to your application. This ensures the bearing will last longer and work better in your equipment.

If you use the right INA supplement codes, you make sure your replacement bearing fits and performs as needed. This helps you avoid downtime and keeps your machines running smoothly.

Cross-Reference for Needle Roller Bearings

Popular Models and Equivalents

When you look for needle roller bearings, you will see many common models. These models work in lots of machines. Some popular series are TA, HK, HF, NK, NA, RNA, AXK, and KT. Each series is good for different jobs. For example, TA and HK series are used in car and factory gearboxes. The HF series is used in one-way clutch systems. NK, NA, and RNA series fit in tight spaces. The RNA series does not have an inner ring, so it is great for textile machines and printing presses. The AXK series can hold heavy loads, so it is good for transmissions and farm tools. The KT series is small and light, so it is used in engines and pumps.

You can find similar needle roller bearings from many big brands, and use a cross reference chart to match bearings from one brand to another.

Here is a simple table that shows popular series and their cross-brand matches:

| Series | Typical Application | Brands with Equivalents |

|---|---|---|

| HK | Gearboxes, transmissions | IKO, INA, SKF, NSK, NTN, FAG |

| RNA | Textile, packaging | IKO, INA, SKF, NSK, NTN, FAG |

| AXK | Axial load, heavy industry | IKO, INA, SKF, NSK, NTN, FAG |

| KT | Engines, compressors | IKO, INA, SKF, NSK, NTN, FAG |

Cross-Brand Reference Tips

There are some important things to remember when you use a cross reference chart for needle roller bearings. Always check the part numbers very carefully. Be careful not to mix up numbers and letters, like zero and O, or one and I. Use group numbers to help you find parts that can be swapped.

Look at the prefix and suffix codes. These codes tell you about special features, like cage type or design changes. Make sure the size matches, including the bore, outside diameter, and width. Check the load capacity to make sure the new bearing will work in your machine.

Watch out for design differences. Some needle roller bearings have special chamfers or taper angles. These small changes can change how the bearing fits. Sometimes, unground straight roller bearings are put with ground bearings to meet swap rules.

Tip: Always check the cross reference chart twice and compare all sizes before you pick a replacement. This helps you avoid mistakes and keeps your machines working well.

Cautions for Bearing Replacement

Tolerances and Fit

It is important to check tolerances and fit when changing bearings. The right fit helps your bearing work well and last longer. If you pick the wrong fit, you can get problems like too much wear, shaking, and noise. Sometimes, the bearing might move in its spot. This is called bearing creep. It can hurt both the bearing and the machine.

Bearings need to fit tightly on shafts and in housings. There are three main fit types: interference, slip, and transition. Interference fits need force to put together and stop slipping. These are used on the spinning ring. Slip fits are easy to put together and have a little resistance. They are used on the ring that does not move. Transition fits are between interference and slip fits.

Some common problems with tolerance and fit are:

- Bearing creep, which makes the bearing move and causes damage.

- The inner race can shift and change the preload.

- Not enough stiffness, which can lower part quality.

- The inner race can lift off and spin on the shaft.

- The shaft can get out of line and cause wobbling.

- Other bearings can get damaged if the fit is too loose.

- Too much shaking, which can hurt parts and machines.

Loose fits in the housing can make things shake and not line up. Tight fits on the shaft can make the bearing less efficient and not last as long. Tight fits in the housing can make more heat and shorten bearing life. Small movements from loose fits can cause rust and faster wear. Always measure carefully and use the right tools to avoid mistakes. The best fit depends on your job, load, and bearing type. Picking the right fit is very important for bearing life and stopping early failure.

Application Environment

You must think about where the bearing will be used before picking a new needle roller bearing. Things like dirt, dust, water, heat, and electricity can change how the bearing works. If you do not think about these things, the bearing can fail early and cost more to fix.

Dirt and dust can get inside and wear out the bearing. Water and wet air can cause rust and break down the grease. High heat can change the bearing’s material and make it weaker. Electricity can make small pits and damage the bearing’s surface.

To keep your needle roller bearings safe, use good seals to block dirt and water. Pick grease that works for the heat and place. For wet or rusty places, use bearings made from special materials or with coatings. If there is electricity, use insulated bearings to stop sparks.

How fast the bearing spins also matters. Fast speeds make more heat and force. You need bearings with the right materials, grease, and design for these jobs. In dirty places, seals and special materials help stop wear and keep grease clean. In clean rooms or vacuums, you may need bearings that grease themselves or are made from special stuff to stop dirt.

If you match the bearing to the place it will be used, it will last longer and need less fixing. The right bearing helps your machine run well and not break down.

Installation and Handling

Putting in and handling needle roller bearings the right way is very important. Many problems happen because people make mistakes when putting in or touching the bearings. You can stop these problems by following good steps.

Here are some simple steps for putting in and taking care of bearings:

- Keep bearings in a clean, dry place at room temperature. Leave them in their box until you need them.

- Wear gloves when you touch bearings to keep them clean and stop rust.

- Check the shaft and housing to make sure they are clean and not damaged.

- Use special tools, like pullers and heaters, so you do not scratch or break the bearing.

- Put the bearing in the right way. Do not hit the wrong ring. Make sure the fit matches the bearing and job.

- Use the right kind and amount of grease. Pick grease that matches the place, heat, speed, and load.

- Line up the machine shafts before you start. Bad alignment can wear out the bearing and lower how much it can hold.

- Balance the machine to stop extra force on the bearing.

- Do not use bearings outside their heat range. Too much heat can change the shape and break the bearing.

- Replace bearings with ones that are just as good or better. This helps them fit right and last longer.

You should also turn stored bearings sometimes to stop damage from shaking. After putting in the bearing, clean it with grease and add the right amount before using it. Always follow the maker’s rules for putting in and taking care of bearings.

If you do these things, your bearings will work better and not break as much. Careful handling and good installation help your needle roller bearings hold more weight and last longer.

Tip: Do not hurry when putting in bearings. Take your time and check everything. This will help you save time and money later.

TFL Bearings as a Cross-Brand Solution

Quality and Standards

You want your bearing to work well and last long. TFL Bearings follow strict world rules, so you can trust them. The company has ISO 9001, which means they check every bearing carefully. Before making lots of bearings, TFL gives samples to test. They check each bearing again before sending it out. This makes sure every bearing is strong and works well for you.

TFL Bearings promise three things: good quality, honesty, and great service. Their products meet RoHS and REACH rules, so they are safe and good for the earth. You can use TFL bearings instead of many other brands. They fit the same and work for precision crossed roller bearings and more.

- ISO 9001 certified for quality management

- Pre-production samples and final inspections

- Compliance with RoHS & REACH standards

- Interchangeable with major brands

- Over 28 million bearings delivered worldwide

Pricing and Delivery

You need bearings that are quick to get and not too expensive. TFL Bearings give you good quality for less money than big brands. Their bearings are as good as NSK and FAG but cost less. TFL keeps many bearings in stock, so you can get common ones in 48 hours. Most orders come in 3 to 5 days. Fast shipping helps you fix machines quickly and avoid waiting.

- Competitive pricing for all bearing types

- Fast shipping for urgent repairs

- Large stock of precision crossed roller bearings and other models

- Delivery in 3–5 days for most orders

Quick delivery and fair prices help you fix problems fast and keep your work going.

Why Choose Us

You want a company that knows what you need. TFL Bearings gives you more than just bearings. You get help, advice, and many choices for your job. The team helps you pick the right bearing, even for hard jobs with precision crossed roller bearings. TFL is known for strong performance, trust, and good help after you buy. You can count on TFL for all your bearing needs and upgrades.

| Benefit | What You Get |

|---|---|

| High performance | Reliable operation and long life |

| Fast delivery | Less downtime, quick repairs |

| Wide selection | Bearings for every application |

| Expert support | Help with choosing and installing |

Pick TFL Bearings for your next replacement. You will get better results, faster help, and a team that cares about your success.

You can replace a bearing the right way by following easy steps. First, look at the bearing code and check a cross-reference chart. Always make sure the bearing fits your job, like in a factory or car. For needle roller bearings, think about how much weight, speed, heat, and sealing you need. Here is a simple checklist to help you:

- Keep all bearings clean and dry at all times.

- Check the fit, seals, and grease for every bearing.

- Use the right tools and never hit the bearing directly.

- Listen and feel for noise, heat, or shaking in the bearing.

- Only use new bearings that match the old ones exactly.

Pick TFL Bearings if you want good quality, quick shipping, and a fair price for your work.

FAQ

What should you do if you cannot find the exact bearing code match?

You can look at a cross-reference chart to find a similar bearing. Always check the size, how much weight it can hold, and any special features. If you are not sure, ask a bearing expert for help. This makes sure your new bearing is safe and fits your machine.

How do you know if a cross-brand bearing will fit your machine?

Check the size, type, and suffix codes on the bearing. Compare these with your old part. Use a cross-reference chart to double-check. If you notice any differences, talk to technical support before you put it in.

Can you reuse old seals or cages when replacing bearings?

Always use new seals and cages when you change bearings. Old parts might be worn out or have hidden damage. New seals and cages help your bearing last longer and keep dirt and leaks away from your machine.

What is the best way to store spare bearings?

Keep bearings in a dry and clean place. Store them in their original box or bag. Do not let sunlight or water touch them. Turn the bearings sometimes so they do not get damaged from sitting still.

Why do you need to check bearing clearance and tolerance before installation?

Checking clearance and tolerance stops noise, too much heat, and early failure. This helps the bearing fit tight and work smoothly. Always measure before you put it in to avoid mistakes that cost money.