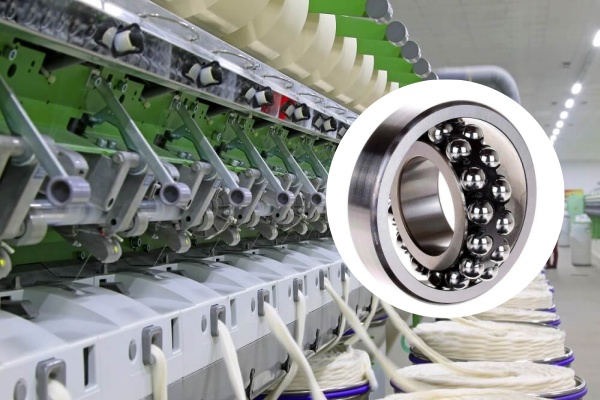

In high-precision machinery, even small alignment errors can lead to increased friction, vibration, premature wear, and reduced service life. Shafts may deflect under load, housings may not be perfectly aligned, and thermal expansion can introduce unexpected angular deviations during operation. In such environments, standard bearing solutions often struggle to maintain consistent performance. This is where self-aligning ball bearings play a critical role.

Self-aligning ball bearings are specifically designed to accommodate misalignment between the shaft and housing without compromising smooth operation. Their unique internal geometry allows them to adjust automatically to angular deviations, making them an ideal choice for precision machinery operating under variable alignment conditions. This guide explains how self-aligning ball bearings work, their key features, advantages, limitations, and where they are most effectively used.

What Are Self-Aligning Ball Bearings

Self-aligning ball bearings are a type of rolling bearing that uses two rows of balls and a common spherical raceway in the outer ring. This spherical raceway allows the inner ring, balls, and cage assembly to tilt freely relative to the outer ring. As a result, the bearing can automatically compensate for shaft misalignment or housing inaccuracies during operation.

Unlike rigid bearing types, self-aligning ball bearings are tolerant of angular misalignment caused by shaft deflection, mounting errors, or structural deformation. This self-correcting ability helps maintain smooth rotation, reduces stress concentrations, and prevents edge loading on the rolling elements.

From the Factory Floor: Need a reliable source for high-volume bearing orders? As a direct bearing manufacturer, SDTFL ensures consistent quality control and competitive factory pricing for all standard self-aligning series.

How Self-Aligning Ball Bearings Work

The defining feature of self-aligning ball bearings is the spherical shape of the outer ring raceway. This geometry allows the bearing’s internal components to pivot slightly within the outer ring. When the shaft becomes misaligned, the bearing adjusts its internal orientation rather than forcing the rolling elements into unfavorable contact angles.

This automatic alignment mechanism reduces internal friction and prevents excessive stress on the balls and raceways. As a result, self-aligning ball bearings can operate reliably even when perfect alignment cannot be guaranteed, which is common in long shafts, flexible structures, or lightly supported assemblies.

Key Design Features of Self-Aligning Ball Bearings

Self-aligning ball bearings incorporate several design features that distinguish them from other ball bearing types. The double-row ball configuration improves load distribution and stability during operation. The spherical outer raceway enables compensation for angular misalignment without external adjustments.

These bearings are typically available with cylindrical or tapered bores, allowing flexibility in mounting methods. Many designs also include cages made from steel, brass, or polymer materials, selected based on speed, temperature, and lubrication requirements. Some variants are supplied with seals or shields to protect against contamination in demanding environments.

SDTFL Bearings stands ready to meet these diverse needs with a robust supply chain. We stock and manufacture the full spectrum of self-aligning ball bearings, giving you immediate access to steel, brass, and polyamide cage variants. Whether you need a single replacement or a bulk wholesale order for your production line, our factory ensures consistent quality and rapid availability across all series.

Self-Aligning Ball Bearings vs Standard Ball Bearings

Compared to standard deep groove ball bearings, self-aligning ball bearings offer superior tolerance to misalignment. Standard ball bearings require precise shaft and housing alignment to function properly. Even minor deviations can significantly reduce their service life.

Self-aligning ball bearings, by contrast, are designed specifically to handle these deviations. While they may have slightly lower load capacity than some standard ball bearings of comparable size, their ability to accommodate misalignment often results in better real-world reliability and reduced maintenance needs.

Load Capacity and Performance Characteristics

Self-aligning ball bearings are primarily designed to carry radial loads, with limited capacity for axial loads in either direction. Their double-row design improves radial load handling compared to single-row ball bearings, but they are not intended for heavy axial loading.

In high-precision machinery, their performance advantage lies in smooth rotation, low friction, and consistent operation under varying alignment conditions. They are particularly effective in applications where loads are moderate but alignment stability cannot be guaranteed.

Speed Capability and Efficiency

Due to their ball-based rolling elements, self-aligning ball bearings can operate at relatively high speeds compared to roller bearing alternatives. Their low-friction characteristics make them suitable for applications requiring efficient rotation and minimal energy loss.

However, operating speed limits depend on factors such as bearing size, cage material, lubrication method, and sealing configuration. Proper selection ensures that speed capability aligns with application requirements without compromising bearing life.

Advantages of Using Self-Aligning Ball Bearings

One of the most significant advantages of self-aligning ball bearings is their ability to compensate for angular misalignment automatically. This reduces installation precision requirements and simplifies assembly in complex machinery.

Additional benefits include reduced vibration and noise, improved operational stability, and extended service life in misalignment-prone systems. By minimizing internal stress and uneven load distribution, these bearings help protect surrounding components such as shafts and housings.

Limitations and Considerations

While self-aligning ball bearings offer excellent misalignment tolerance, they are not suitable for every application. Their axial load capacity is limited, and they may not be ideal for systems subjected to heavy thrust loads.

In addition, their load capacity is generally lower than that of spherical roller bearings or tapered roller bearings. For applications involving extreme loads or shock conditions, alternative bearing types may be more appropriate. Understanding these limitations is essential for correct bearing selection.

Typical Applications of Self-Aligning Ball Bearings

Self-aligning ball bearings are widely used in applications where shaft deflection, structural flexibility, or mounting inaccuracies are common. Typical uses include textile machinery, agricultural equipment, conveyor systems, fans, blowers, and paper processing machines.

They are also frequently used in precision machinery such as printing equipment, packaging machines, and automation systems, where smooth operation and alignment tolerance are critical. In many cases, their use helps reduce downtime and maintenance costs by preventing premature bearing failure.

Lubrication and Maintenance Practices

Proper lubrication is essential for maximizing the performance and service life of self-aligning ball bearings. Depending on operating conditions, bearings may be lubricated with grease or oil. Grease lubrication is common for moderate-speed applications, while oil lubrication may be preferred for higher speeds or elevated temperatures.

Regular inspection, contamination control, and adherence to recommended lubrication intervals help ensure reliable operation. Sealed versions can further reduce maintenance requirements in dusty or moisture-prone environments.

SDTFL Self-Aligning Ball Bearing Product Range

To meet the diverse needs of our industrial clients, we manufacture and supply a comprehensive range of self-aligning ball bearings. Our factory produces the following key series:

- 1200 & 1300 Series: The industry standard for general misalignment applications, available with cylindrical or tapered bores.

- 2200 & 2300 Series: Wider design featuring higher load-carrying capacity, ideal for heavy-duty industrial machinery.

- Adapter Sleeve Assemblies (H Series): Complete kits including adapter sleeves, lock nuts, and washers for easy mounting on plain shafts.

- Sealed Variations (2RS): Factory-sealed options to prevent contamination in harsh environments like textile mills and agricultural sites.

All series are manufactured under strict ISO quality standards.

Selecting the Right Self-Aligning Ball Bearing

Choosing the correct self-aligning ball bearing involves evaluating load requirements, operating speed, alignment conditions, environmental exposure, and mounting constraints. Bore type, clearance class, cage material, and sealing options should be matched to the specific application.

Consulting technical specifications and performance data helps ensure that the selected bearing delivers optimal efficiency and durability. Correct selection not only improves machinery performance but also reduces total operating costs over the equipment’s lifecycle.

Self-aligning ball bearings are an essential solution for high-precision machinery operating under conditions prone to misalignment. Their unique ability to accommodate angular deviations while maintaining smooth, low-friction rotation makes them invaluable in many industrial and precision applications.

By understanding how self-aligning ball bearings work, their advantages and limitations, and how to select the right design, engineers and buyers can make informed decisions that enhance reliability, efficiency, and long-term performance.

Ensure Precision with SDTFL Bearings

At SDTFL Bearings, we understand that in high-precision machinery, there is no room for error. Misalignment shouldn’t mean downtime. We are committed to providing you with top-tier self-aligning ball bearings that ensure your operations run smoothly, efficiently, and reliably.

Whether you are designing a new system or replacing components in existing equipment, our team is ready to support you with expert advice and premium products.

Take the next step toward operational excellence:

- Contact Us: Reach out directly to discuss your specific requirements.

- Request a Quote: Email your specifications to info@sdtflbearing.com.

- Speak to an Expert: Call us at +86 15806631151 for immediate assistance.

Partner with us today and let us help you keep your world rotating.