Choosing the right bearing is critical for machinery performance, operational efficiency, and long-term service life. Bearings play a fundamental role in reducing friction, supporting loads, and ensuring smooth motion in rotating and linear systems. Among the many bearing types available, one of the most common and important comparisons engineers, maintenance professionals, and procurement teams face is ball bearings vs roller bearings.

While both bearing types are designed to minimize friction between moving components, their internal construction, load-handling capabilities, speed limits, and operating characteristics differ significantly. Selecting the wrong bearing type can lead to premature failure, excessive wear, increased energy consumption, and costly downtime. Understanding the functional differences between ball bearings and roller bearings helps ensure that the selected bearing matches the application’s operating conditions, load requirements, and performance expectations.

What Are Ball Bearings

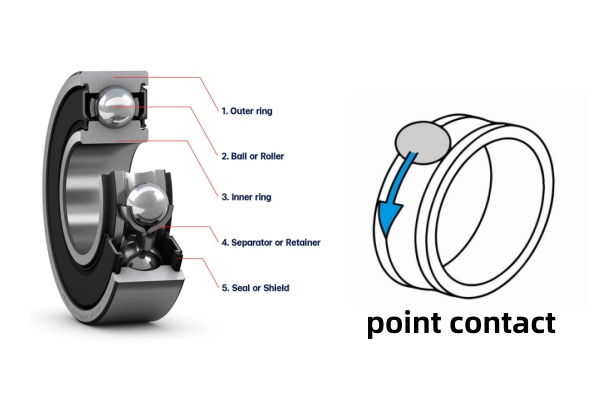

Ball bearings use spherical rolling elements positioned between an inner race and an outer race. These balls rotate freely, creating point contact with the raceways. Because the contact area is small, friction is minimized, allowing ball bearings to operate smoothly and efficiently at high speeds.

Ball bearings are designed to support both radial and axial loads, although their load-carrying capacity is limited compared to roller bearings. They are particularly valued for their low friction, quiet operation, and ability to maintain precise motion control. Due to these characteristics, ball bearings are widely used in applications where speed, accuracy, and low noise levels are more important than heavy load capacity.

Common designs include deep-groove ball bearings, angular-contact ball bearings, and self-aligning ball bearings, each suited to specific operating conditions and load directions.

Common Ball Bearing Series (High Speed & Precision):

- 6000, 6200, 6300 Series: Deep Groove Ball Bearings (Versatile, most common).

- 7000, 7200, 7300 Series: Angular Contact Ball Bearings (For combined loads).

- 1200, 1300, 2200 Series: Self-Aligning Ball Bearings (Corrects misalignment).

What Are Roller Bearings

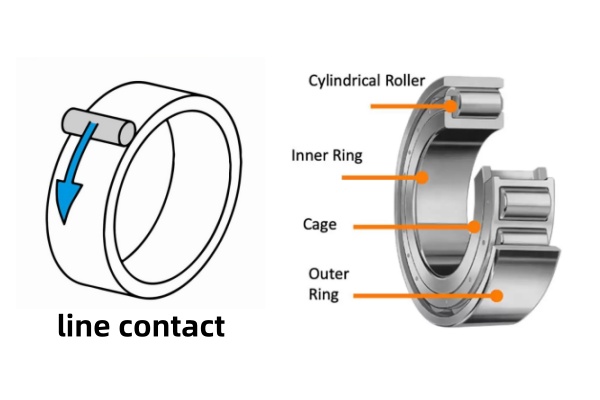

Roller bearings use cylindrical, tapered, spherical, or needle-shaped rolling elements instead of balls. Unlike ball bearings, roller bearings create line contact with the raceways rather than point contact. This increased contact area allows loads to be distributed more evenly across the bearing surfaces.

Because of this design, roller bearings are capable of supporting much higher loads than ball bearings. They are particularly effective in applications involving heavy radial loads, shock loads, or combined radial and axial forces. Roller bearings are commonly found in industrial machinery, heavy equipment, and systems that operate under continuous or demanding conditions.

Different roller bearing types serve different purposes. Cylindrical roller bearings are optimized for high radial loads, tapered roller bearings handle combined loads, spherical roller bearings compensate for misalignment, and needle roller bearings provide high load capacity in compact spaces.

Common Roller Bearing Series (High Load & Durability):

- NU, NJ, NUP Series: Cylindrical Roller Bearings (Heavy radial loads).

- 30200, 32200, 31300 Series: Tapered Roller Bearings (Heavy combined loads).

- 22200, 22300 Series: Spherical Roller Bearings (Heavy loads + misalignment).

- NA, NK Series: Needle Roller Bearings (Compact design).

Ball Bearings vs Roller Bearings: Key Differences

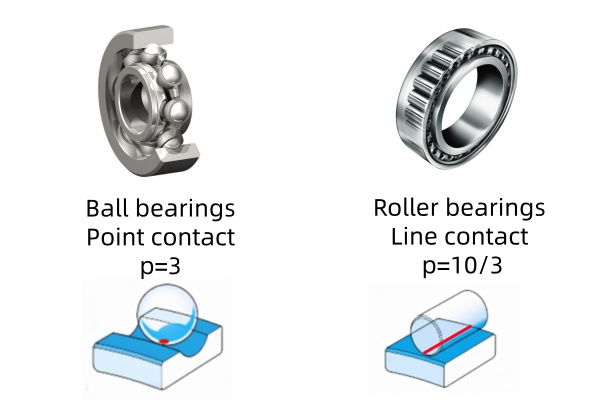

The fundamental difference in ball bearings vs roller bearings lies in their contact geometry. Ball bearings rely on point contact between the rolling elements and raceways, while roller bearings rely on line contact. This structural difference directly affects performance, load capacity, speed capability, and durability.

Ball bearings generally offer lower friction, smoother motion, and higher speed capability. Roller bearings, on the other hand, provide greater load-bearing strength and improved durability in heavy-duty applications. The choice between the two depends on whether speed or load capacity is the dominant requirement in the application.

Load Capacity Comparison

Load capacity is one of the most important factors when comparing ball bearings vs roller bearings. Roller bearings have a significantly higher load capacity due to their line contact design, which spreads the load over a larger surface area. This makes them ideal for applications involving heavy radial loads, impact forces, or continuous stress.

Tapered roller bearings are particularly effective in handling combined radial and axial loads, making them suitable for gearboxes, automotive axles, and industrial transmissions. Spherical roller bearings can accommodate both high loads and shaft misalignment, further enhancing reliability in harsh environments.

Ball bearings, by contrast, are better suited for light to moderate loads. While they can support both radial and axial forces, excessive loading can shorten their service life. They are most effective when smooth operation and speed are prioritized over heavy load support.

Not sure if your load requirements demand a ball or roller design? Let our experts help you calculate the optimal load rating for your specific application. Email us at info@sdtflbearing.com for a free consultation.

Speed and Operating Performance

Speed capability is another key distinction between ball bearings and roller bearings. Ball bearings perform exceptionally well at high rotational speeds because their point contact design reduces friction and heat generation. This allows them to maintain efficiency and stability even at elevated RPM levels.

High-speed motors, fans, pumps, and precision instruments often rely on ball bearings for consistent and reliable operation. Their low friction also reduces energy consumption, making them suitable for applications where efficiency is critical.

Roller bearings generally operate best at moderate speeds. While they can handle substantial loads, the increased friction from line contact can lead to higher heat generation at very high speeds. For this reason, roller bearings are typically selected for strength and durability rather than speed.

Durability and Service Life

When properly selected and installed, both ball bearings and roller bearings can provide long service life. However, their durability depends heavily on operating conditions and load profiles. Roller bearings tend to offer longer service life in heavy-load applications because the load is distributed more evenly across the rolling elements.

Ball bearings demonstrate excellent longevity in high-speed, low-load environments. Their simpler design and reduced friction help minimize wear when used within their intended limits. Using ball bearings in applications with excessive loads can lead to premature fatigue, surface damage, and early failure.

Correct bearing selection, proper lubrication, and routine maintenance are essential for maximizing service life regardless of bearing type.

Typical Applications of Ball Bearings

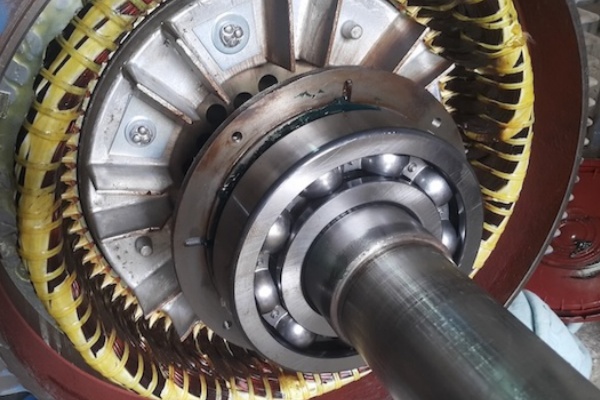

Ball bearings are widely used across a broad range of industries due to their versatility and efficiency. Common applications include electric motors, generators, pumps, household appliances, automotive accessories, and precision instruments. They are also commonly used in robotics, medical devices, and light industrial equipment.

Their ability to operate quietly and smoothly makes them especially suitable for applications requiring precise motion control and minimal vibration. In many cases, ball bearings are the preferred choice for compact designs with space constraints.

Typical Applications of Roller Bearings

Roller bearings are commonly used in applications where strength, durability, and load capacity are critical. Typical applications include gearboxes, conveyors, construction equipment, wind turbines, mining machinery, steel mills, and heavy industrial drives.

They are also widely used in railway systems, agricultural machinery, and large rotating equipment where bearings must withstand continuous operation under challenging conditions. Roller bearings are often selected for environments involving shock loads, misalignment, or variable loading.

Cost and Maintenance Considerations

From a cost perspective, ball bearings are generally more economical, especially for smaller machines and high-speed applications. Their simpler design and widespread availability make them a cost-effective solution for many standard uses.

Roller bearings often involve higher initial costs due to their robust construction and specialized designs. However, in heavy-duty applications, they can provide better long-term value by reducing maintenance frequency, minimizing unexpected failures, and extending service intervals.

Maintenance requirements vary depending on operating conditions, lubrication practices, and environmental exposure. Proper lubrication and contamination control are critical for both bearing types.

Looking for a cost-effective solution without sacrificing quality? We provide competitive pricing on both standard and custom orders. Fill out our inquiry form to get our latest price list today.

How to Choose Between Ball Bearings and Roller Bearings

When deciding between ball bearings vs roller bearings, several key factors should be considered. Load magnitude and direction, operating speed, alignment conditions, environmental exposure, and space constraints all play a role in bearing selection.

Ball bearings are the better choice for applications requiring high speed, low friction, and precision. Roller bearings are more suitable for applications involving heavy loads, shock forces, and demanding industrial conditions. Careful evaluation of these factors ensures optimal performance, safety, and equipment lifespan.

Understanding the differences between ball bearings and roller bearings is essential for making informed engineering and purchasing decisions. Each bearing type offers distinct advantages depending on application requirements. By evaluating load capacity, speed, durability, and operating conditions, you can confidently select the bearing that best supports your machinery’s performance and long-term reliability.

Still undecided? You don’t have to choose alone. Send your technical specifications to info@sdtflbearing.com, and the SDTFL team will recommend the perfect bearing type for your project.

Partner with SDTFL Bearings for the Perfect Fit

Selecting between ball bearings vs roller bearings is just the first step. To ensure your machinery runs at peak efficiency, you need a partner who understands the nuances of load, speed, and environmental demands.

At SDTFL Bearings, we specialize in manufacturing high-performance bearing solutions tailored to your specific industry requirements. Whether you need the high-speed precision of our deep groove ball bearings or the rugged durability of our tapered roller series, we have the inventory and engineering expertise to keep your operations moving.

Don’t let the wrong bearing choice slow you down.

- Request a Quick Quote: Send your requirements to info@sdtflbearing.com

- Speak to an Engineer: Call us at +86 15806631151

- Explore Our Catalog: Visit our product page via the sidebar to see our full range.

Contact us today to optimize your equipment’s performance and lifespan.