Introduction

Needle roller bearings are everywhere. You’ll find them in cars, motorcycles, industrial machines, and even some power tools. They handle loads well and take up less space than regular ball bearings. But what makes them work so smoothly? One big factor is the cage inside them.

The cage in a needle roller bearing holds the rollers in place, keeping them from rubbing against each other. This helps reduce friction and keeps the bearing running longer. If you’re wondering why cage design matters or which type is best for your needs, you’re in the right place. Let’s break it down in simple terms.

What is a Needle Roller Bearing Cage?

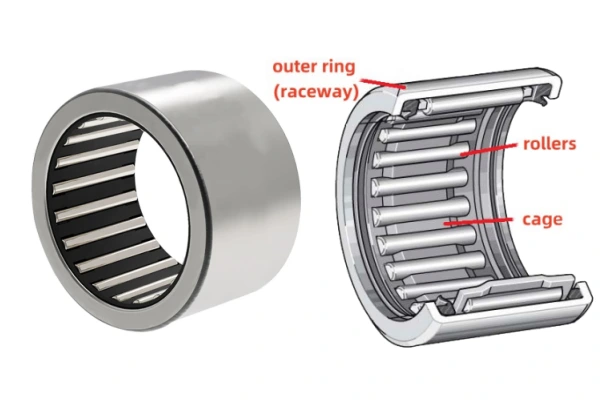

Think of the needle roller bearing cage like a special organizer for all those tiny needle rollers. It’s like a little holder that keeps each roller in its own spot. This way, they don’t all just bunch up together.

What Does a Cage Do?

This little organizer has some really important jobs to do:

- Keeps Rollers Apart

Imagine trying to roll a bunch of pencils all at once. They’d probably bump into each other and not roll very well, right? The cage stops the needle rollers from touching. This means they can roll without getting in each other’s way, making things move much smoother.

- Spaces Rollers Evenly

The cage also makes sure the rollers are spread out nicely inside the bearing. If they were all crowded on one side, it wouldn’t work very well. By keeping them evenly spaced, the cage helps share the weight from whatever the bearing is holding up. This helps the bearing last longer without wearing out too fast.

- Helps with Speed

Sometimes, things need to spin really fast! The cage helps with that too. It keeps the rollers lined up properly so they don’t go flying around when things are moving quickly. This makes the bearing work better even when the speed picks up.

Why is the Cage Important in Caged Roller Bearings?

You might hear the term caged roller bearing. That just means a needle roller bearing that has one of these helpful cages inside. And trust me, the cage is super important! Without it, the bearing wouldn’t be able to do its job very well. The rollers would just clump together, rub against each other, and the whole thing could break down pretty quickly. So, the cage makes sure your caged roller bearing is strong and will keep things moving for a long time.

Different Kinds of Needle Roller Bearings and Their Cages

Caged Roller Bearings: What Are They?

A caged roller bearing has a structure that holds the rollers in place. This design reduces friction and allows for better performance in high-speed or heavy-load conditions. Compared to full-complement needle bearings (which have no cage), caged roller bearings are better for applications that require smooth operation and longevity.

Needle Roller Thrust Bearings and Their Cage Design

A thrust needle roller bearing is designed to handle loads in one direction (axial loads). The cage in these bearings keeps the rollers aligned, preventing them from slipping out of place. This makes them ideal for applications like automotive transmissions and gearboxes.

Drawn Cup Needle Roller Bearings and Their Cage Design

Drawn cup needle roller bearings have a thin-walled outer shell that looks like a small cup. The cage inside helps hold the rollers, making these bearings compact yet strong. They’re often used in small spaces where regular bearings wouldn’t fit, like in motorcycles or hand tools.

Types of Materials Used in Needle Roller Bearing Cages

Now, not all cages are made the same. The material of the cage can make a big difference depending on where you’re using the bearing. Here are some common options:

- Steel: Strong and durable, steel cages are great for heavy-duty applications.

- Brass: Brass is softer than steel but still tough enough for many jobs. It’s also resistant to rust, which is helpful in wet environments.

- Plastic: Lightweight and cost-effective, plastic cages work well in low-load or low-speed situations.

Conclusion

So, you see, the needle roller bearing cage might seem like a small part, but it does a really big job in a needle roller bearing. It’s like the peacekeeper for the rollers, making sure they stay organized, move smoothly, and help your machines last longer. Whether it’s in a regular caged roller bearing, a needle roller thrust bearing, or drawn cup needle roller bearings, that little cage is a real hero!

Looking for strong and dependable needle roller bearings? At TFL Bearings, we make really good bearings with carefully made cages. We want to help your machines run the best they can. Want to know more or get a price? Get in touch with us at TFL Bearings today!

5 Popular Related Questions About Needle Roller Bearings

What are needle roller bearings used for?

Needle roller bearings are used in lots of different machines and vehicles to help parts move smoothly and with less rubbing. You can find them in things like car gearboxes, engines, and even some of the tools you might use at home.

How is a needle roller bearing different from a bearing with balls in it?

Some bearings use round balls to roll, like marbles. Needle roller bearings use rollers that are long and thin, like needles. These needle rollers can often handle heavier stuff in a smaller space compared to ball bearings.

What would happen if a bearing didn’t have a cage?

If a needle roller bearing didn’t have a cage, all the little rollers would rub against each other. This would cause more heat and make the bearing wear out much quicker. It might even break down and stop working.

Do needle roller bearings cost a lot of money?

The price of needle roller bearings can change depending on how big they are, what kind they are, and what they’re made of. But often, they can be a good, affordable choice for many different uses.

How can I tell if I need a needle roller bearing?

If you need a bearing that can hold up heavy things but doesn’t have a lot of room to fit, a needle roller bearing might be the right choice. It’s always a good idea to check the instructions for your machine or talk to someone who knows a lot about bearings.