How Insulated Bearings Safeguard Wind Turbines from Electrical Damage

Wind turbine insulated bearings prevent electrical erosion, reducing downtime and maintenance costs while extending turbine lifespan and reliability.

Wind turbine insulated bearings prevent electrical erosion, reducing downtime and maintenance costs while extending turbine lifespan and reliability.

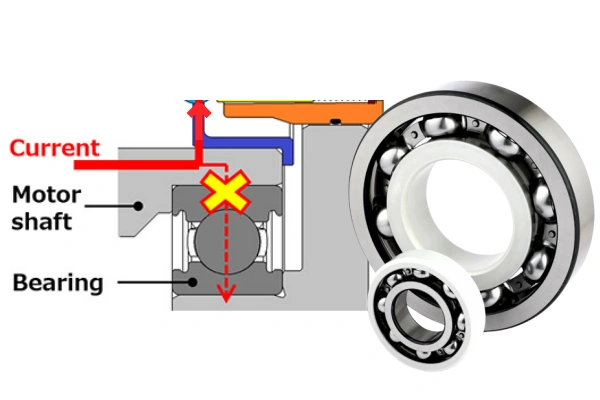

Insulated bearings in VFD motors prevent electrical damage, boost reliability, and cut maintenance costs by reducing bearing failures and downtime.

Assess roller bearings with simple checks, cleaning, and proper lubrication to prevent failure and extend equipment life. Follow these easy maintenance steps.

Roller bearings in linear guide systems cut downtime by 70% and lower maintenance costs, boosting assembly line reliability and equipment lifespan.

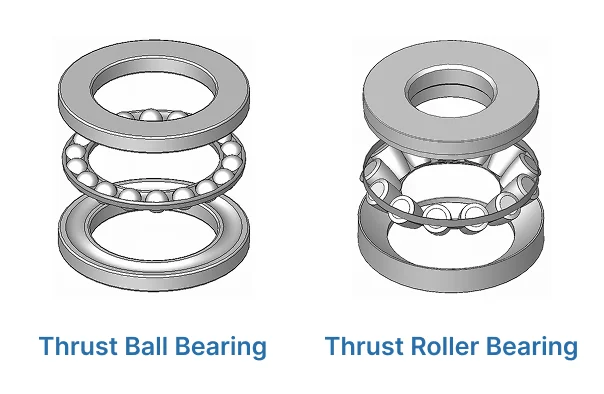

Thrust bearings and washers boost machine speed, load, and lifespan by up to 50% by reducing friction, wear, and heat for reliable, efficient operation.

Roller bearings sealing structures protect against contaminants and retain lubricant, ensuring longer bearing life and reliable performance in various applications.

Identify defective ball bearings by checking for noise, vibration, overheating, or visible damage. Learn when ball bearing replacement is necessary to avoid failures.

Learn how to correctly install and remove deep groove ball bearings, master cold installation, hot installation, drawing and other methods to ensure the life of the bearing and the safe operation of the equipment. Detailed tool recommendations and operating points are included to help you maintain efficiently!