Needle roller bearing: features, applications, and advantages

Needle roller bearing offers high load capacity, compact design, and durability, making it ideal for automotive, industrial, and aerospace applications.

Needle roller bearing offers high load capacity, compact design, and durability, making it ideal for automotive, industrial, and aerospace applications.

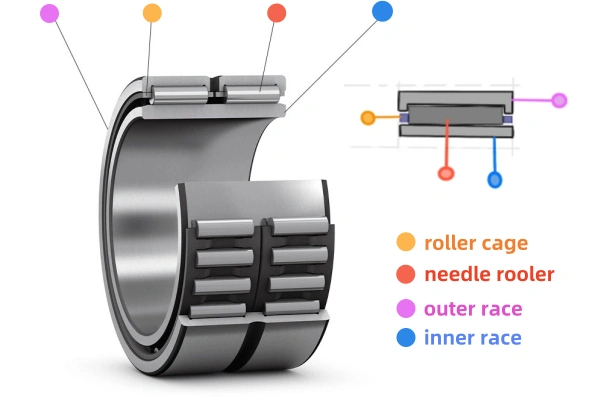

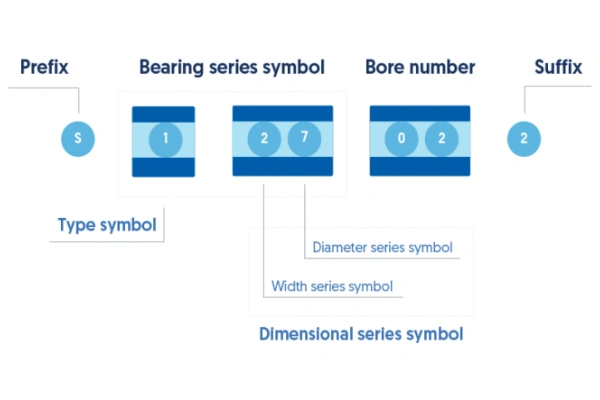

Roller bearing sizes and codes explained for buyers—understand what each number means and how to select the right bearing for your application.

Roller bearings use high-carbon chromium steel, ceramics, and plastics for strength, durability, and performance in various industrial applications.

Roller bearings include cylindrical, needle, spherical, tapered, and thrust types, each designed for specific load and alignment needs in machinery.

A roller bearing uses rollers for line contact, offering higher load capacity and durability for heavy-duty machines in 2025 applications.

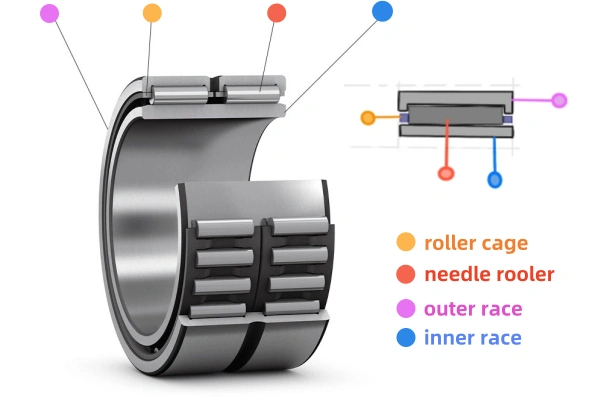

This article provides a comprehensive overview of needle roller bearing cages, explaining their crucial role in ensuring smooth operation, reducing friction, and extending bearing life. It delves into the function of the cage, different types of needle roller bearings (caged, thrust, and drawn cup), and the various materials used in cage construction. The article concludes by addressing common questions about needle roller bearings and their applications.

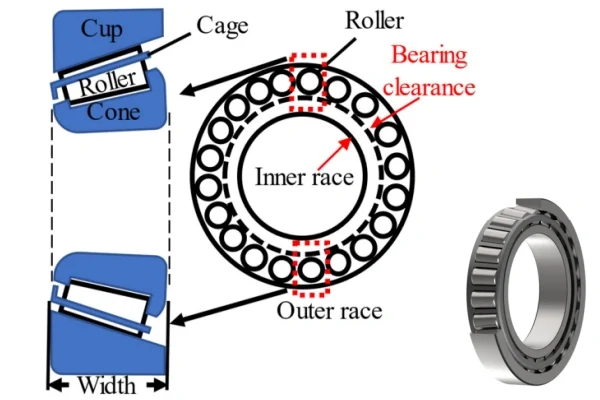

Learn what roller bearing clearance is, why it matters, and how to measure it. From radial vs. axial clearance to using tools like feeler gauges, this guide makes it simple to keep your bearings running smoothly.