Roller Bearing vs Ball Bearing Key Differences and Best Uses

Compare roller bearing vs ball bearing to see which suits heavy loads or high speeds. Find key differences and best uses for your machinery needs.

Compare roller bearing vs ball bearing to see which suits heavy loads or high speeds. Find key differences and best uses for your machinery needs.

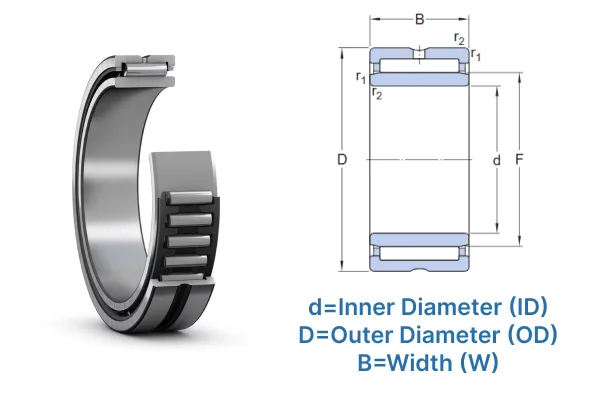

Match needle roller bearing sizes to your shaft and housing by measuring ID, OD, and width, then use a size chart for the best fit and performance.

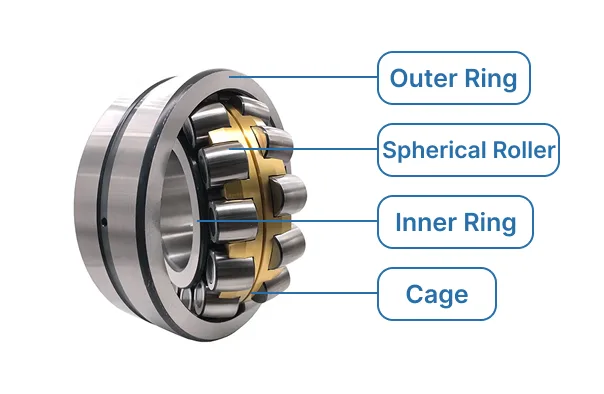

A spherical roller bearing uses barrel-shaped rollers to support heavy loads and self-align, reducing friction and handling shaft misalignment efficiently.

A cross roller bearing uses crossed cylindrical rollers for high strength, accuracy, and compact size, making it ideal for robots and precision machines.

Tapered roller bearing design supports both radial and axial loads, making it ideal for automotive, industrial, and heavy machinery applications.

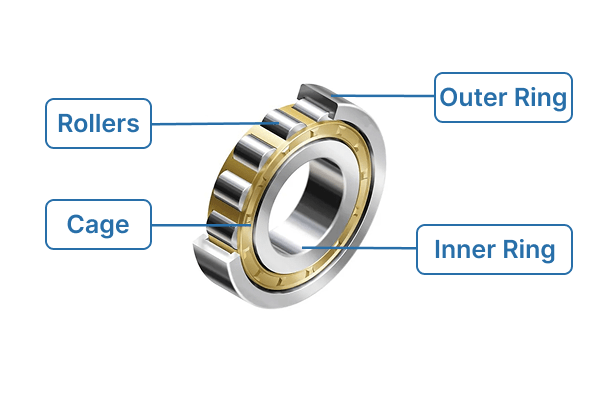

Cylindrical roller bearing structure supports heavy radial loads, offers high speed, and ensures durability for industrial, automotive, and machinery uses.

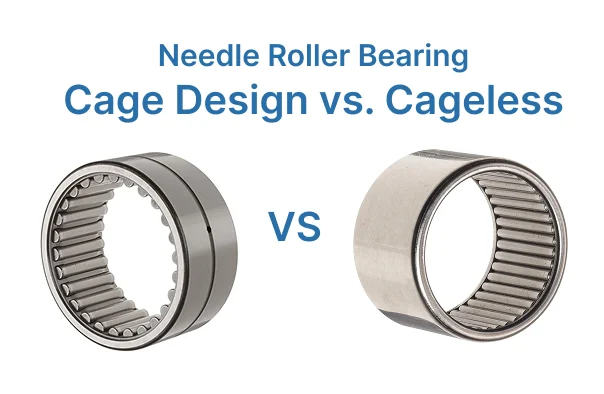

Caged Design in needle roller bearings offers smoother operation, higher speed, and less maintenance, while cageless types excel in heavy load capacity.

Roller bearings sealing structures protect against contaminants and retain lubricant, ensuring longer bearing life and reliable performance in various applications.