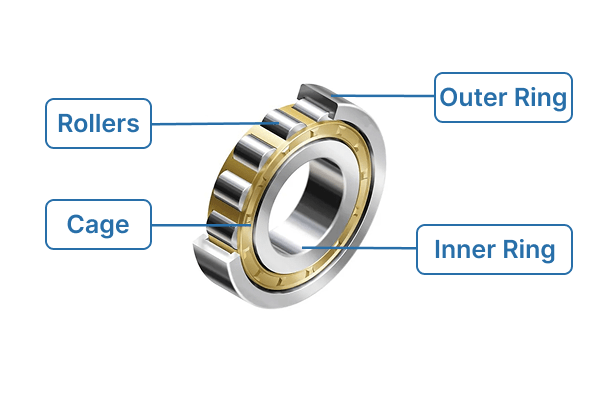

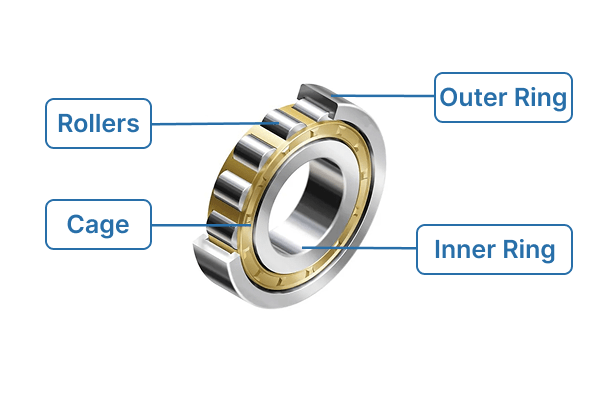

Cylindrical Roller Bearing: Structure, Uses, And Performance

Cylindrical roller bearing structure supports heavy radial loads, offers high speed, and ensures durability for industrial, automotive, and machinery uses.

Cylindrical roller bearing structure supports heavy radial loads, offers high speed, and ensures durability for industrial, automotive, and machinery uses.

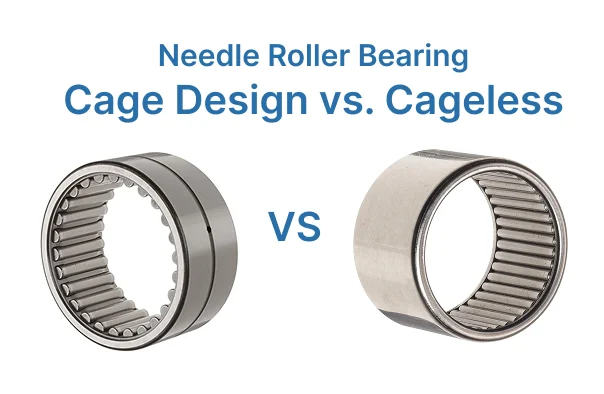

Caged Design in needle roller bearings offers smoother operation, higher speed, and less maintenance, while cageless types excel in heavy load capacity.

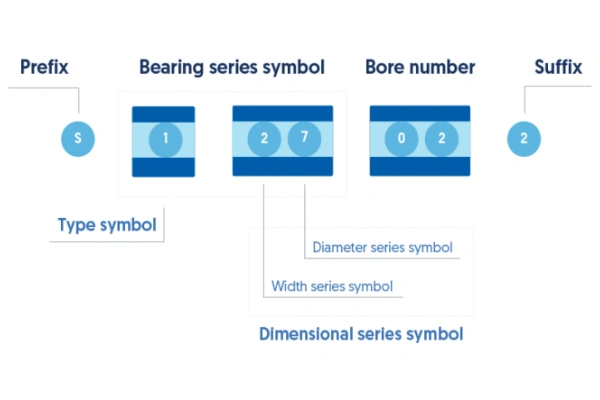

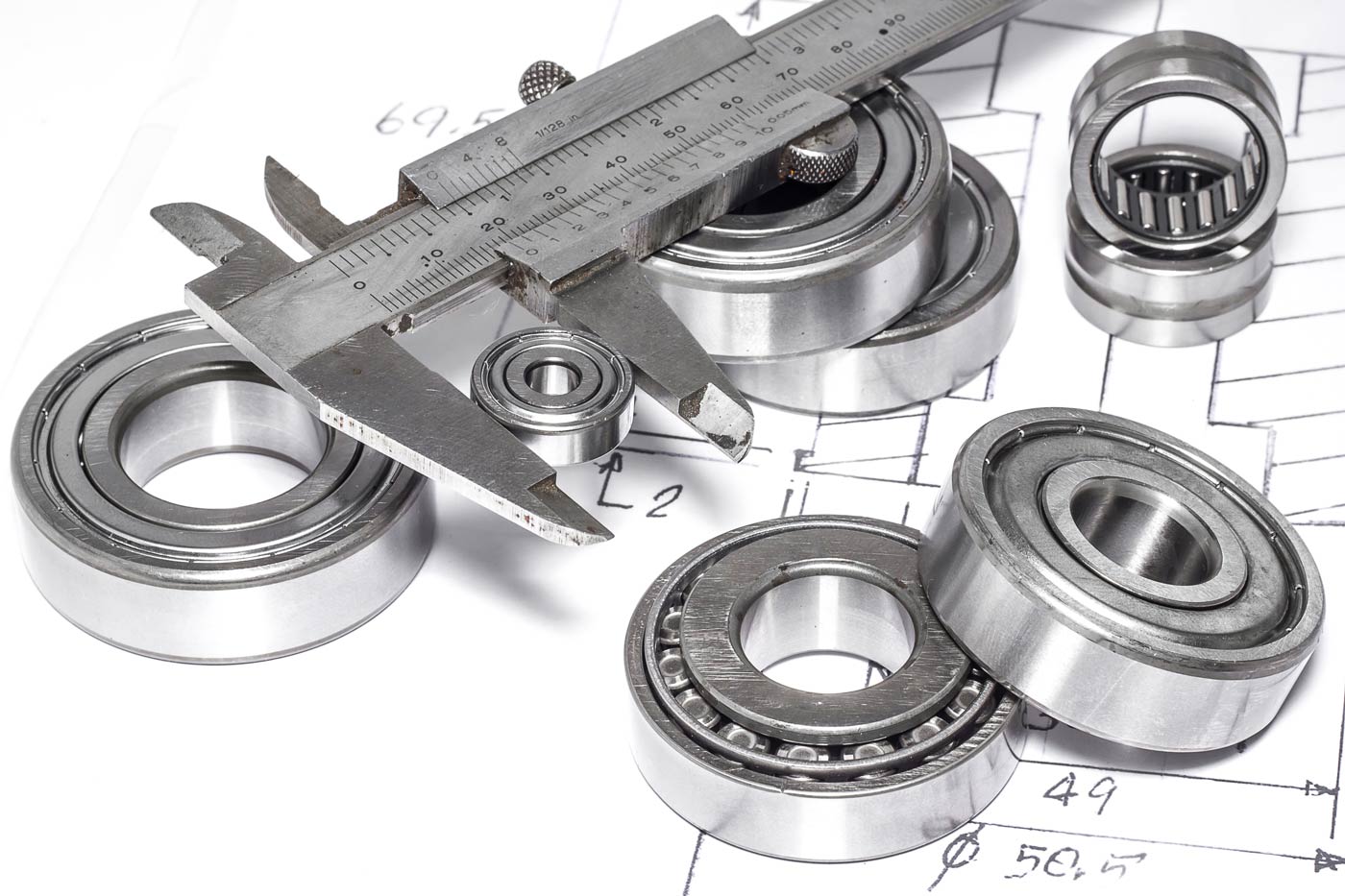

Roller bearing sizes and codes explained for buyers—understand what each number means and how to select the right bearing for your application.

High precision ball bearings offer tighter tolerances, longer life, and lower vibration than standard types—worth the cost for demanding applications.

Insulated Ball Bearings 6310M/C3VL0241 block stray currents, preventing electrical damage and extending motor life in high-voltage industrial applications.

Ball bearings reduce friction in bikes and cars by enabling smoother, more efficient movement, leading to better performance and longer-lasting parts.

Select the right flanged ball bearing by matching load, speed, environment, and fit to your application for optimal performance and reliability.

Easily choose the right bearing with a flanged ball bearing size chart—measure shaft, flange, and width for a secure fit and reliable performance.