How to buy stainless steel bearings from China safely and efficiently

Safely buy stainless steel bearings China by verifying suppliers, checking quality, using secure payments, and managing shipping for efficient orders.

Safely buy stainless steel bearings China by verifying suppliers, checking quality, using secure payments, and managing shipping for efficient orders.

TFL Bearings for EV Motors offer proven reliability, low noise, and fast delivery, making them the trusted choice for top Chinese EV manufacturers.

Find the best SKF bearing alternative fast with tips on specs, quality, brands, and sourcing for reliable performance and quick delivery.

Choose a reliable Chinese miniature bearing factory by checking experience, certifications, product range, and strong quality control for lasting performance.

Are Chinese ceramic bearings worth it? We cut through the hype with real user reviews. Find out what makes a good bearing and how to get a smooth ride without the big price tag.

TFL offers high-quality NSK-Compatible Bearings in China with strict quality control, competitive pricing, fast delivery, and expert support.

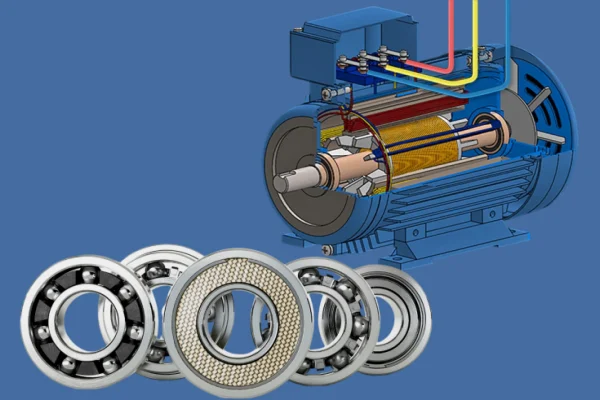

TFL’s Motor Bearings offer ultra-quiet performance, durability, and cost efficiency, making them the top choice for global brands sourcing from China.

Verify wholesale bearings from China suppliers by checking licenses, certifications, reviews, and requesting samples to ensure quality and reliability.