Understanding the Design and Uses of Cross Roller Bearings in 2025

Cross roller bearing design enables high load capacity, precision, and durability for robotics, medical devices, and machine tools in 2025.

Cross roller bearing design enables high load capacity, precision, and durability for robotics, medical devices, and machine tools in 2025.

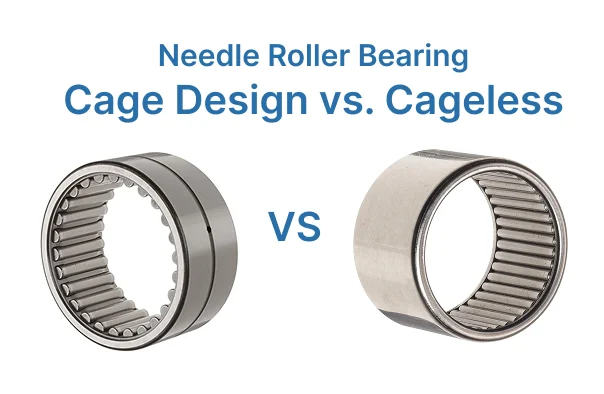

Caged Design in needle roller bearings offers smoother operation, higher speed, and less maintenance, while cageless types excel in heavy load capacity.

Roller bearings sealing structures protect against contaminants and retain lubricant, ensuring longer bearing life and reliable performance in various applications.

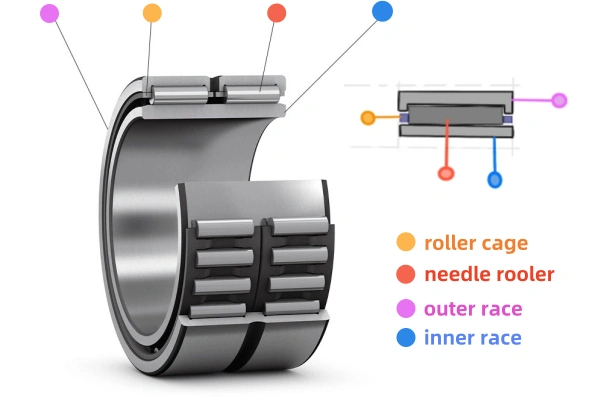

Needle roller bearing offers high load capacity, compact design, and durability, making it ideal for automotive, industrial, and aerospace applications.

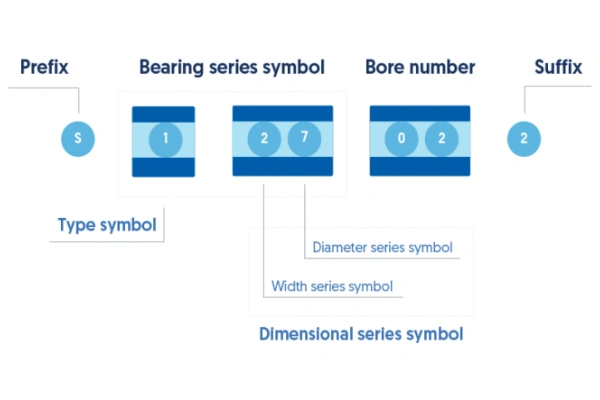

Roller bearing sizes and codes explained for buyers—understand what each number means and how to select the right bearing for your application.

Koyo needle roller bearings save space and boost performance with compact design, high load capacity, and durability for automotive and industrial use.

Roller bearings use high-carbon chromium steel, ceramics, and plastics for strength, durability, and performance in various industrial applications.

High precision ball bearings offer tighter tolerances, longer life, and lower vibration than standard types—worth the cost for demanding applications.