Home / Product / Roller Bearings / Needle Roller Bearings / Thrust Needle Roller Cage Assemblies & Thrust Washers / Needle Roller Thrust Bearing Washers

Needle Roller Thrust Bearing Washers

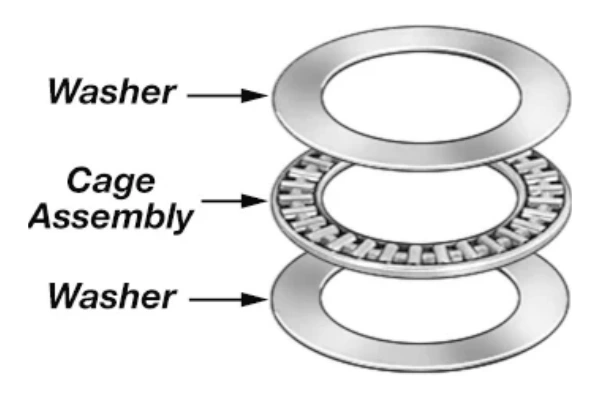

These specialized washers are critical components in thrust bearing assemblies, especially with needle roller bearings. They provide a hardened, smooth, and precise running surface for needle rollers to operate against. This ensures efficient load transfer and minimizes friction and wear on adjacent machine parts. Needle roller thrust bearing washers are engineered to withstand heavy axial loads, making them indispensable in applications requiring high rigidity and accurate axial positioning. Their design supports optimal performance and extends the lifespan of the entire thrust bearing system.

Loading...

Total 136 Results

Part Number

Brand

Interchangeable

Bore Dia

Bore Dia Tolerance

Outer Dia

Outer Dia Tolerance

Width

System of Measurement

Material

Temperature Range

RoHS

Weight

AS3552

TFL

INA

35 mm

0.05mm to 0.3mm

52 mm

-0.520mm to -0.06mm

1 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

9 g

LS3552

TFL

INA

35 mm

0.05mm to 0.3mm

52 mm

-0.520mm to -0.06mm

3.5 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

27 g

AS4060

TFL

INA

40 mm

0.05mm to 0.3mm

60 mm

-0.520mm to -0.06mm

1 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

12 g

LS4060

TFL

INA

40 mm

0.05mm to 0.3mm

60 mm

-0.520mm to -0.06mm

3.5 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

37 g

AS4565

TFL

INA

45 mm

0.05mm to 0.3mm

65 mm

-0.520mm to -0.06mm

1 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

13 g

LS4565

TFL

INA

45 mm

0.05mm to 0.3mm

65 mm

-0.520mm to -0.06mm

4 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

47 g

AS5070

TFL

INA

50 mm

0.05mm to 0.3mm

70 mm

-0.520mm to -0.06mm

1 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

14 g

LS5070

TFL

INA

50 mm

0.05mm to 0.3mm

70 mm

-0.520mm to -0.06mm

4 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

51 g

AS5578

TFL

INA

55 mm

0.06mm to 0.360mm

78 mm

-0.520mm to -0.06mm

1 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

18 g

LS5578

TFL

INA

55 mm

0.06mm to 0.360mm

78 mm

-0.520mm to -0.06mm

5 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

82 g

AS6085

TFL

INA

60 mm

0.06mm to 0.360mm

85 mm

-0.612mm to -0.072mm

1 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

22 g

LS6085

TFL

INA

60 mm

0.06mm to 0.360mm

85 mm

-0.612mm to -0.072mm

4.75 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

92 g

AS6590

TFL

INA

65 mm

0.06mm to 0.360mm

90 mm

-0.612mm to -0.072mm

1 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

24 g

LS6590

TFL

INA

65 mm

0.06mm to 0.360mm

90 mm

-0.612mm to -0.072mm

5.25 mm

Metric

Spring Steel

-30° to 110 °C

Compliant

110 g

The Essential Role of Thrust Washers

Thrust washers are fundamental to the proper functioning of any thrust bearing system, particularly those incorporating needle roller bearings. They act as critical interfaces, distributing axial loads evenly and preventing direct contact between rotating and stationary components. Without a suitable thrust washer, the lifespan and efficiency of the thrust bearing would be significantly reduced due to premature wear on adjacent machine parts. Our thrust washers are designed for high performance, offering reliable support for continuous operation in demanding environments.

Material and Design of Needle Roller Thrust Bearing Washers

Needle roller thrust bearing washers are precisely manufactured from materials chosen for their hardness and wear resistance, such as high-carbon chromium steel or specialized bronze thrust washer alloys. Their flat, ring-shaped design ensures uniform load distribution over the entire contact area with the needle rollers. Precision grinding and heat treatment processes are often employed to achieve the required surface finish and dimensional accuracy. These carefully designed thrust washers contribute significantly to the high load capacity and rigidity characteristic of needle roller thrust bearings. We offer a range of needle roller bearing dimensions for compatibility.

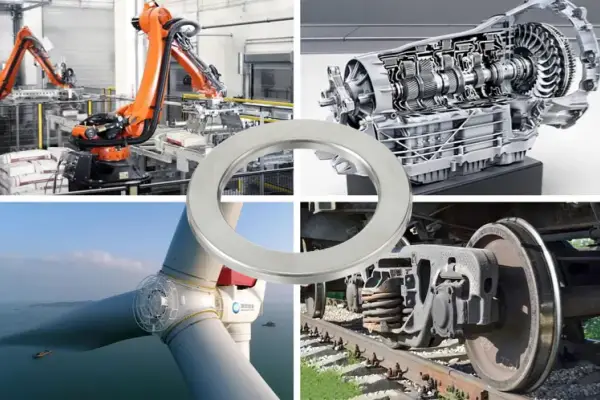

Applications and Benefits in Bearing Systems

Needle roller thrust bearing washers are widely utilized in applications where axial loads are significant and space is limited. Common thrust bearing applications include automotive transmissions, gearboxes, steering systems, and hydraulic pumps. The benefits of using these specialized washers are numerous: they reduce friction, minimize wear on adjacent components, enhance the thrust bearing’s load capacity, and contribute to the overall smooth and reliable operation of machinery. Their compact nature makes them suitable for a wide range of industrial bearings and assemblies requiring precise axial support.

FREQUENTLY ASKED QUESTIONS

What is the main function of a needle roller thrust bearing washer?

The main function of a needle roller thrust bearing washer is to provide a hard, smooth, and parallel raceway surface for the needle rollers within a thrust bearing assembly. This ensures efficient load transfer and prevents wear on adjacent machine parts that are not hardened for bearing operation.

Are there different types of materials used for these washers?

Yes, needle roller thrust bearing washers are typically made from high-carbon chromium steel, which is hardened and ground for precision. Some specialized applications may use other materials, such as a bronze thrust washer for specific environmental or performance requirements.

How do these washers affect the lifespan of a thrust bearing?

Needle roller thrust bearing washers significantly extend the lifespan of a thrust bearing by providing an optimal running surface for the needle rollers. This reduces friction and wear within the bearing assembly and on surrounding components, leading to greater durability and reliable long-term performance in various thrust bearing applications.

Can these washers be used with all types of thrust bearings?

While specifically designed for use with needle roller thrust bearings, the concept of a thrust washer is common to many thrust bearing types. However, the specific dimensions and material properties of needle roller thrust bearing washers are optimized for needle rollers to achieve maximum efficiency and load capacity. It’s always best to match the washer to the specific bearing roller bearing system.