Home / Product / Roller Bearings / Cylindrical Roller Bearings / Single Row Cylindrical Roller Bearings / Single Row Cylindrical Roller Bearings With Inner Ring

Single Row Cylindrical Roller Bearings With Inner Ring

Single row cylindrical roller bearings with an inner ring are designed to handle high radial loads while maintaining smooth operation. These bearings are widely used in machine tools, compressors, and conveyor systems. Their robust design ensures reliability and consistent performance in demanding industrial environments.

Loading...

Total 1282 Results

Part Number

Interchangeable

Bore Dia

Outer Dia

Width

System of Measurement

For Load Direction

Inner Ring Type

Dynamic Radial Load

Static Radial Load

Weight

NJ 18/1120 ECMA

SKF

1120 mm

1360 mm

106 mm

Metric

Combined

With Inner Ring

767250 lbf

1946250 lbf

341 kg

NJ 18/1180 ECMA

SKF

1180 mm

1420 mm

106 mm

Metric

Combined

With Inner Ring

681750 lbf

1755000 lbf

350 kg

NUP 29/1180 ECMA/HA1

SKF

1180 mm

1540 mm

206 mm

Metric

Combined

With Inner Ring

2018250 lbf

4860000 lbf

1100 kg

315913

SKF

1250 mm

1500 mm

106 mm

Metric

Combined

With Inner Ring

387000 lbf

933750 lbf

332 kg

NJ 18/1320 ECMA

SKF

1320 mm

1600 mm

122 mm

Metric

Combined

With Inner Ring

1003500 lbf

2565000 lbf

536 kg

N 28/1400 ECMP

SKF

1400 mm

1700 mm

175 mm

Metric

Combined

With Inner Ring

1485000 lbf

4117500 lbf

865 kg

319301

SKF

1500 mm

1820 mm

140 mm

Metric

Combined

With Inner Ring

742500 lbf

1800000 lbf

653 kg

NU 18/1700 ECMA/HB1

SKF

1700 mm

2060 mm

160 mm

Metric

Combined

With Inner Ring

1622250 lbf

4342500 lbf

1150 kg

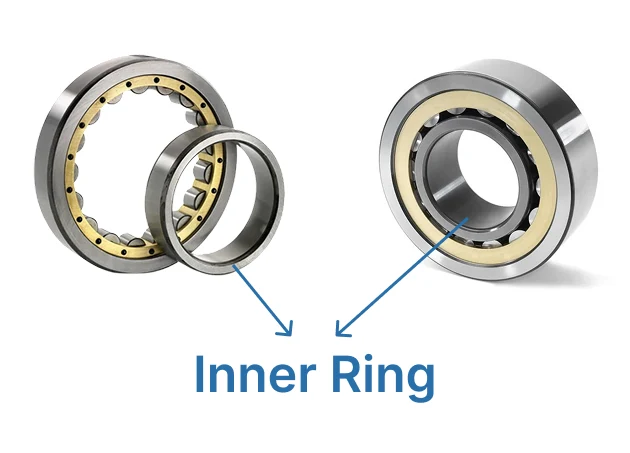

The Inner Ring Provides Greater Strength

Single-row cylindrical roller bearings with inner rings are mainly composed of outer rings, inner rings, cylindrical rollers and cages. The inner ring, as a key component directly mating with the shaft, has an inner diameter precisely matching the shaft journal and an outer diameter in contact with the rollers. It is usually axially fixed to the shaft through parts such as shaft shoulders, lock nuts and retaining rings to prevent axial deviation.

In addition to the positioning function, this type of inner ring is generally made of high-strength materials such as chrome steel and has smooth raceways that match the rollers. This not only enhances the overall strength of the bearing but also reduces friction, enabling high-precision rotation of the bearing. For applications with high radial load requirements and high precision demands, single-row cylindrical roller bearings with an inner ring have an irreplaceable position.

Superior Radial Load-Carrying Capacity

Like most cylindrical roller bearings, the single row cylindrical roller bearing with an inner ring has the most notable advantage of high radial load-carrying capacity. This line contact structure enables the stress to be evenly distributed on the bearing, enhancing its rigidity.

At the same time, this single-row structure also makes the bearing’s load-carrying more flexible, allowing it to withstand extremely high radial forces within a limited space, making it an ideal choice for high radial load-carrying in confined spaces.

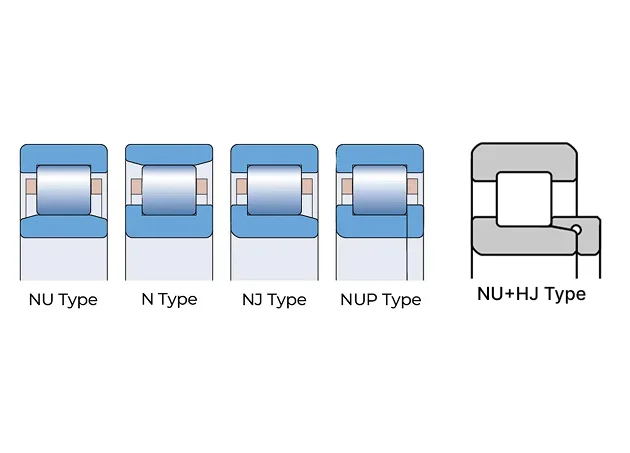

A Variety of Flange Types

Single row cylindrical roller bearings with inner rings come in various design types based on the different configurations of the inner and outer ring flanges.

- NU type bearings: The outer ring has two integral flanges, while the inner ring has none.

- N-type bearings: Contrary to NU-type bearings, N-type bearings have two integral flanges on the inner ring and none on the outer ring.

- NJ type bearings: This type of bearing has two integral flanges on the outer ring and one integral flange on the inner ring.

- NUP type bearings: The outer ring has two integral flanges, and the inner ring has one integral flange as well as a plain flange (P) fitted.

- NU type with HJ flange ring: By using an appropriate HJ flange ring (an additional flange), NU type bearings can also achieve axial positioning similar to NJ type or NUP type.

Depending on the different flange configurations, single row cylindrical roller bearings with inner rings play different roles in practical applications. You can choose the type of bearing that suits your needs.

FREQUENTLY ASKED QUESTIONS

What are the main differences between cylindrical roller bearings and deep groove ball bearings?

The main difference lies in load-carrying capacity.

Cylindrical roller bearings are mainly used to withstand extremely high radial loads, while deep groove ball bearings can simultaneously handle radial loads and certain bidirectional axial loads.

If your application mainly involves heavy radial loads, cylindrical roller bearings are the better choice; if the overall load is relatively small and there are bidirectional axial forces, deep groove ball bearings are more suitable.

What do the suffixes E, M, and P in bearing model numbers stand for?

These are common suffixes that represent special designs of bearings.

'E' usually indicates an optimized internal design with higher load-carrying capacity.

'M' typically refers to a brass solid cage, suitable for harsh operating conditions.

'P' usually indicates a glass fiber reinforced nylon 66 cage, suitable for high-speed applications. For specific meanings, please refer to our product details page or contact us.

Is the structure of single row cylindrical roller bearings with inner rings also separable?

Yes, most single row cylindrical roller bearings are separable designs. This design can greatly reduce the installation difficulty and also avoid some unnecessary damage caused during installation.

Do your bearings meet international quality standards?

Yes, we are an ISO-certified bearing manufacturer, and all our bearings strictly comply with international quality standards.