Discover More About TFL Single Row Cylindrical Roller Bearings

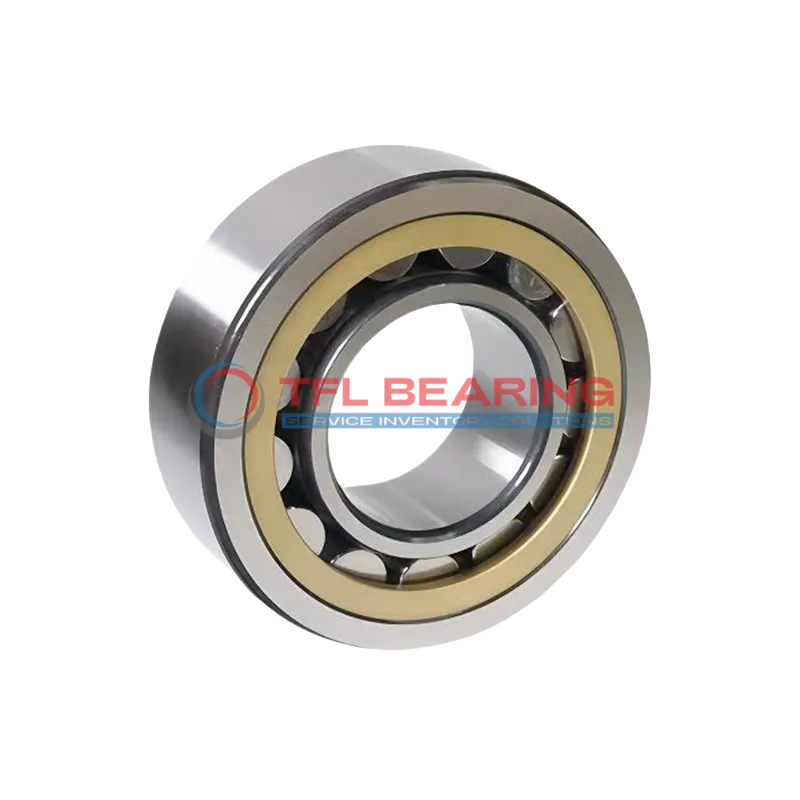

TFL offers single row cylindrical roller bearings including NU, N, NJ and NUP types, ensuring the efficient and reliable operation of your equipment.

Home / Product / Roller Bearings / Cylindrical Roller Bearings / Single Row Cylindrical Roller Bearings

TFL Bearings: High Performance and Reliable

Along with the development of industry, TFL is also constantly enhancing its bearing production capacity, with the goal of becoming a more reliable bearing manufacturer.

-

Top

Product Category

Application

FAQ

Our Process

Hot Products

Support

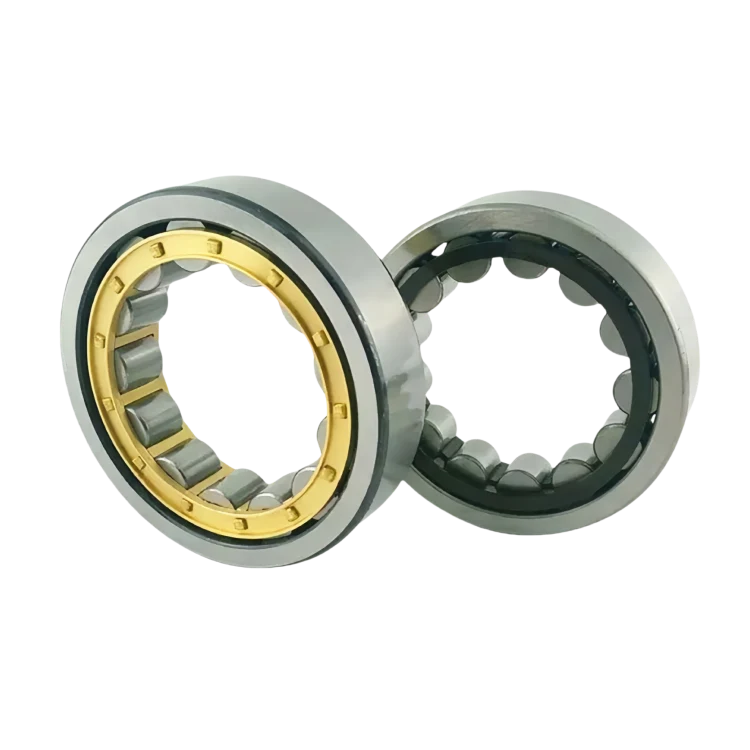

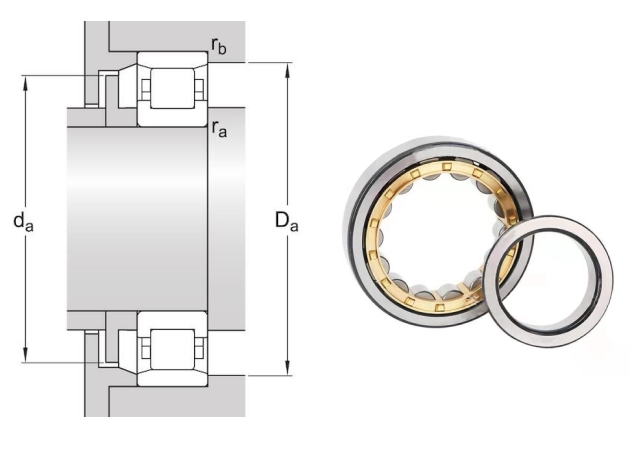

Single Row Cylindrical Roller Bearings Category

Single Row Cylindrical Roller Bearings Category

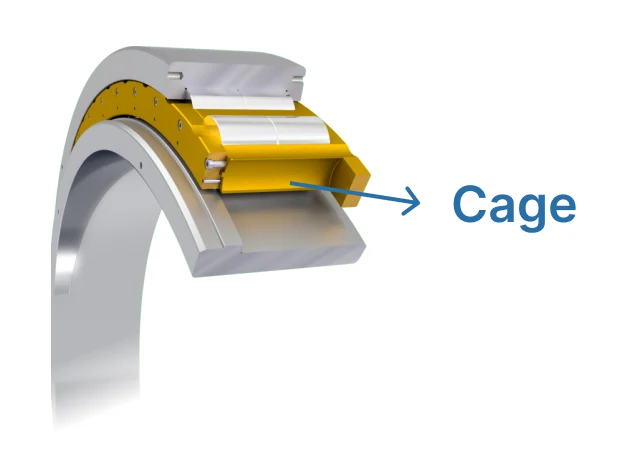

The Cage Makes Single Row Cylindrical Roller Bearings More Stable

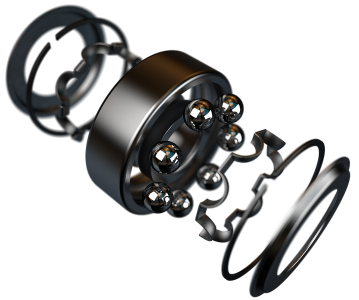

The components of a single row cylindrical roller bearing are relatively simple: solid inner ring, solid outer ring, cylindrical rollers and cage. These components work together to achieve the stable performance of the single row cylindrical roller bearing.

Among them, the cage plays a very important role. The function of the cage is to evenly separate each cylindrical roller, ensuring uniform force on the bearing while also avoiding mutual friction between the rollers. However, the cage itself cannot bear the load, but a cage made of high-performance materials can effectively reduce its own weight, reduce friction, and improve the operating efficiency and service life of the bearing.

Errors and Limitations of the Bearing Angle

Single row cylindrical roller bearings perform exceptionally well in radial load capacity, but their axial load capacity is quite limited. If they must bear a certain axial load, it is necessary to ensure that there is sufficient lubrication in the contact area between the roller end face and the flange to avoid direct contact and wear between metals. However, this axial load capacity is very limited. At the same time, single row cylindrical roller bearings can only tolerate limited angular errors and misalignments.

These limitations are not weaknesses of single row cylindrical roller bearings, but rather they more clearly define its application scope. Choosing the correct bearing and usage method will make your investment twice the result with half the effort.

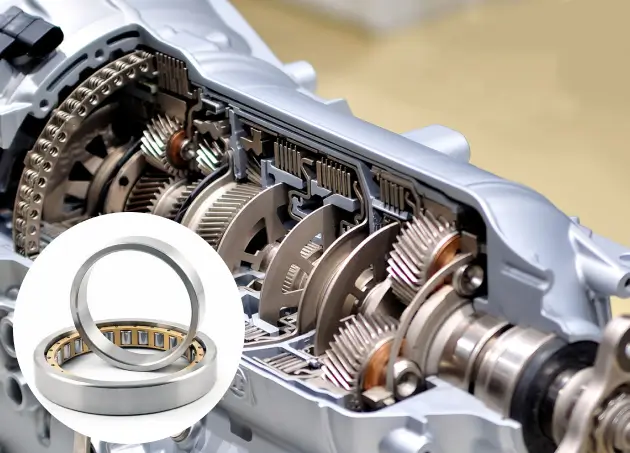

From Heavy Industry to the Application of Precision Machine Tools

Single row cylindrical roller bearings, relying on their unique performance advantages, have been widely applied in various mechanical equipment. As the basic type of cylindrical roller bearings, the single row design is suitable for most standard applications:

Industrial machinery: conveyors, pumps, gearboxes, etc.

Heavy-duty and high-speed conditions: wind energy, metallurgy, construction machinery, mining, cranes

Precision machine tool spindles: high-speed, high-stiffness requirements

Other extensive applications: automobiles, agriculture, medical equipment, household appliances

APPLICATION AREA

Medical Bearings

Medical Bearings The Medical Technology sector develops advanced equipment for diagnostics, treatment,

Marine Bearings

Marine Bearings The Marine Industry operates in one of the planet’s most demanding environments.

Agricultural Bearings

Agricultural Bearings The Agricultural Machinery sector is the backbone of global food production, uti

Heavy Equipment (Construction & Mining)

Heavy-Duty Bearings for Construction and Mining Equipment like excavators, bulldozers, loaders, cranes

INTERCHANGEABLE BRANDS

TFL Bearings: High quality bearings, an ideal choice to replace SKF and FAG.

WHY CHOOSE TFL

QUALITY

Market-proven with over 28 million bearings successfully delivered, and certified under multiple quality management systems, including ISO 9001.

PRICE

By integrating and leveraging China’s robust raw material supply chain, TFL is able to strictly control production costs, thereby offering highly competitive product prices.

FAST DELIVERY

With a vast inventory of over a million bearings, TFL offers solid assurance for your procurement needs. Common bearing models are ready for dispatch within just 48 hours.

FREQUENTLY ASKED QUESTIONS

What are the advantages of single-row cylindrical roller bearings compared to double-row cylindrical roller bearings?

- Simpler structure: Single-row structure has fewer parts, making installation and disassembly easier and reducing costs.

- Better high-speed performance: The single-row structure has less frictional resistance and generates less heat, making it suitable for high-speed applications.

- More suitable for compact spaces: The single-row structure has a smaller width, making it suitable for scenarios with limited axial space.

What materials are general single-row cylindrical roller bearings made of?

Single row cylindrical roller bearings are generally made of chrome steel, which has a high hardness and good high-speed performance, making it suitable for high-speed or heavy-duty applications.

What installation methods are generally used for single row cylindrical roller bearings?

The installation method for bearings can be selected based on their size and the tightness of the fit, either cold installation or hot installation:

- Cold installation: This is suitable for small bearings with a not too tight fit. A sleeve and hammer can be used to gently tap the sleeve to install the bearing in the correct position. During tapping, ensure that the force is evenly distributed on the bearing ring to prevent it from tilting or skewing.

- Hot installation: For larger bearings that require more force to install, hot installation is typically used. By heating the bearing to expand it, it can be more easily installed onto the shaft journal or bearing housing.

For bearings with tapered bores, the inner ring is usually installed with an interference fit on the tapered shaft journal. During installation, the degree of interference fit must be precisely determined by measuring the reduction in radial clearance or the advancement distance of the inner ring on the tapered mating surface.

What payment methods do you offer?

We support multiple payment methods, including Letter of Credit (L/C), bank transfer (T/T), and PayPal, providing convenient options for customers worldwide.

OUR PROCESS

Contact

Initial Contact

01

Budgeting

Specialists Review

Needs

02

Options

Our Engineers Help YouChoose The RightBearings

03

Plant Visit

Option To Visit OurManufacturing Plant

04

Delivery

Your entire order is

delivered.

05

Support

We provide ongoingproduct support

06

HOT PRODUCTS

CAN’T FIND WHAT YOU NEED?

Please provide your question.

We’ll find you with the best support options.