Home / Product / Roller Bearings / Cylindrical Roller Bearings / Four-Row Cylindrical Roller Bearings

Four-Row Cylindrical Roller Bearings

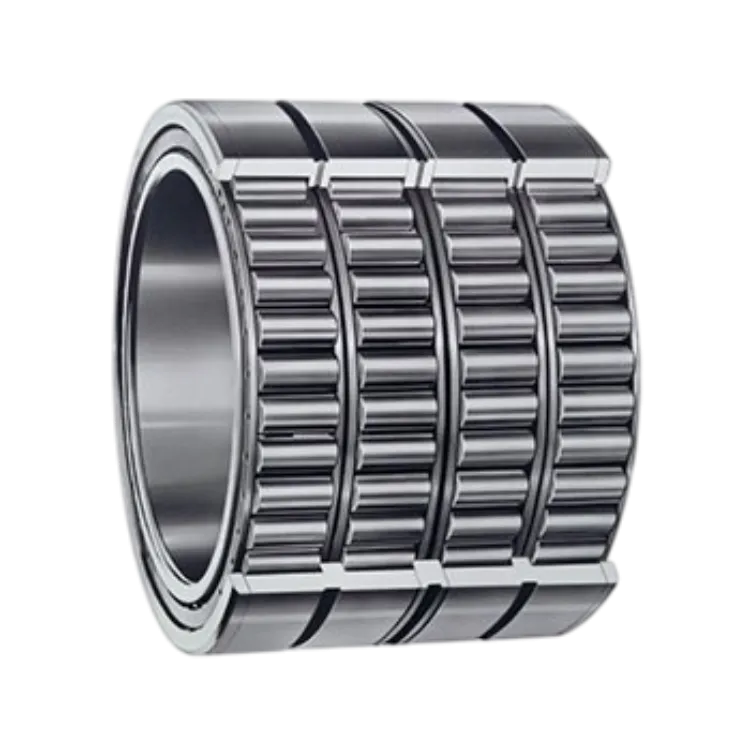

TFL’s Four-Row Cylindrical Roller Bearings are specifically designed to handle the most demanding industrial environments. These robust roller bearings offer an exceptional combination of high radial load capacity, extreme rigidity, and reduced friction. They are the ideal choice for applications subjected to heavy shock loads and continuous operation, ensuring reliability and extended service life for critical machinery.

Loading...

Total 90 Results

Part Number

Brand

Interchangeable

Bore Dia

Outer Dia

Width

Corner Radius/Chamfer Inner Ring(r1,2)(min.)

Chamfer Dimension On The Outer Ring(r3,4)(min.)

Dynamic Radial Load

Static Radial Load

319254/VJ202

TFL

SKF

500 mm

650 mm

260mm

5 mm

5 mm

990000 lbf

2295000 lbf

BC4B 316515

TFL

SKF

500 mm

680 mm

450mm

6 mm

2 mm

1856250 lbf

4950000 lbf

BC4B 322039/HA1

TFL

SKF

500 mm

670 mm

480mm

12.5 mm

5 mm

1856250 lbf

4950000 lbf

BC4B 322066

TFL

SKF

500 mm

720 mm

400mm

4 mm

1.5 mm

1930500 lbf

3960000 lbf

BC4B 326853/HB1

TFL

SKF

500 mm

738 mm

500mm

10.5 mm

4 mm

2430000 lbf

5220000 lbf

BC4-8007/HB1

TFL

SKF

510 mm

760 mm

550mm

16 mm

3 mm

2722500 lbf

5962500 lbf

BC4-8009/HB1

TFL

SKF

510 mm

730 mm

520mm

17.5 mm

6 mm

2295000 lbf

4950000 lbf

BC4B 319411

TFL

SKF

510 mm

680 mm

500mm

22 mm

3 mm

2178000 lbf

5850000 lbf

312844/VJ202

TFL

SKF

529.91 mm

870 mm

670mm

7.5 mm

7.5 mm

3780000 lbf

7537500 lbf

313535 D

TFL

SKF

536.176 mm

762.03 mm

558.8mm

16 mm

4 mm

2565000 lbf

6525000 lbf

316691

TFL

SKF

550 mm

740 mm

510mm

15 mm

2 mm

2475000 lbf

6075000 lbf

BC4-8046/HB1

TFL

SKF

556 mm

800 mm

580mm

17 mm

6 mm

2362500 lbf

5737500 lbf

313189 A

TFL

SKF

559.84 mm

920 mm

710mm

20 mm

4 mm

4522500 lbf

10237500 lbf

BC4B 322930/HA4

TFL

SKF

560 mm

820 mm

600mm

18.5 mm

6 mm

3195000 lbf

7650000 lbf

Optimized Design for Maximum Radial Load

Compared with single or double row cylindrical roller bearings, the four-row version handles much higher radial loads due to its larger number of rolling elements. These bearings are ideal for rolling mill bearings, electric motor bearings, and gearbox bearings where stability and durability are essential.

TFL ensures every bearing meets strict manufacturing standards. The bearing rings and cages are made from high-quality materials and go through strict heat treatment and grinding processes, which guarantees precision performance in harsh environments.

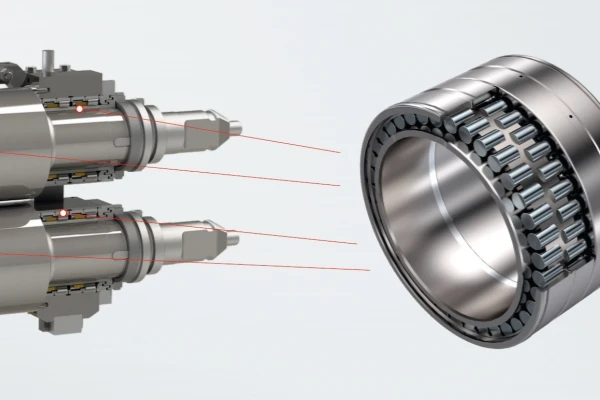

Heavy-Duty Performance in Industrial Applications

Four-row cylindrical roller bearings are widely used in applications such as steel rolling mills, where machines must withstand continuous high radial loads and rapid speeds. The design of these bearings eliminates the need for thrust bearings, reducing space and simplifying the structure.

TFL’s four-row cylindrical bearings provide enhanced load distribution and long-term performance even under extreme working conditions. The precisely machined raceways and optimized roller alignment contribute to lower friction and extended bearing life.

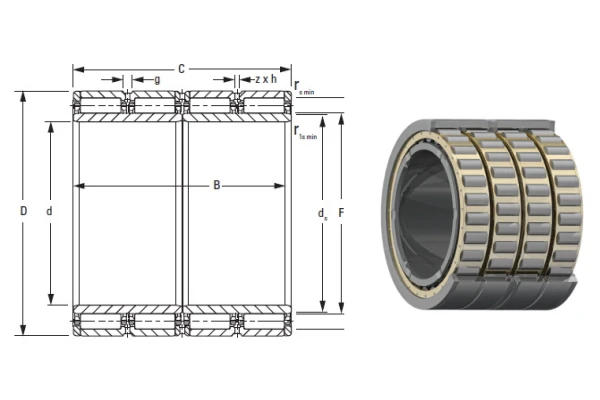

Bearing Dimensions and Custom Solutions

TFL offers a comprehensive cylindrical roller bearing catalog that includes full dimensional specifications and bearing size charts. Customers can find four-row cylindrical roller bearings in a variety of sizes and configurations.

For unique equipment needs, TFL supports custom bearing solutions tailored to specific machinery components. Whether it’s special bearing clearance or precision performance requirements, our engineering support ensures a perfect match.

FREQUENTLY ASKED QUESTIONS

What applications are Four-Row Cylindrical Roller Bearings best suited for?

They are ideal for rolling mills and heavy-duty machinery that operate under high radial loads and require high-speed performance.

How important is lubrication for the performance of these industrial bearings?

Bearing lubrication is absolutely critical, particularly for four-row cylindrical roller bearings operating under extreme conditions in rolling mill environments. Proper lubrication is essential to minimize friction, dissipate heat, and prevent premature wear and damage to the cylindrical rollers and bearing rings. Due to the high speeds and heavy loads, these bearings often utilize circulating oil lubrication systems that filter and cool the oil. Neglecting the proper bearing maintenance and lubrication schedule can quickly lead to catastrophic failure, making it a key factor in maximizing the service life and performance of these precision bearings.

How do Four-Row Bearings differ from Single or Double Row Cylindrical Roller Bearings?

The main difference lies in the load capacity. By incorporating four rows of rolling elements, the four-row configuration offers significantly higher radial load support than single or double row cylindrical roller bearings. This makes them suitable for the extreme loads encountered in rolling mill environments. Single-row bearings are typically used for moderate loads and high speed bearings applications, while double-row types offer a balance of load capacity and compactness. The four-row design is the ultimate choice when maximum stiffness and load rating are the primary concerns.

Can these bearings accommodate axial loads effectively?

While Four-Row Cylindrical Roller Bearings are primarily designed to handle very high radial loads, they do not inherently accommodate significant axial load in the same way thrust bearings do. Their design, focused on radial capacity, means that separate arrangements or additional cylindrical roller thrust bearings might be necessary if substantial axial forces are present in the application. However, their high rigidity can contribute to overall machine stability, indirectly benefiting systems with combined radial and lighter axial loads.