Home / Product / Roller Bearings / Cylindrical Roller Bearings / Double Row Cylindrical Roller Bearings

Double Row Cylindrical Roller Bearings

Double row cylindrical roller bearings are designed to handle higher radial loads compared to single row designs. These bearings are commonly used in gearboxes, rolling mills, and heavy machinery. Their ability to distribute loads evenly ensures optimal performance and longevity.

Loading...

Total 50 Results

Part Number

Brand

Interchangeable

Bore Dia

Outer Dia

Width

Permissible Axial Displacement(max.)

Dynamic Radial Load

Static Radial Load

Max Speed

BC2B 326894/HB1

TFL

SKF

650 mm

920 mm

335mm

5.3 mm

1930500 lbf

5220000 lbf

1000 rpm

BC2-8015/HB1

TFL

SKF

690 mm

980 mm

357.5mm

105 mm

2227500 lbf

6075000 lbf

1000 rpm

BC2-8074/HA5

TFL

SKF

690 mm

980 mm

365mm

9.5 mm

2362500 lbf

6075000 lbf

1000 rpm

NNU 41/710 M/W33

TFL

SKF

710 mm

1150 mm

438mm

20.5 mm

3015000 lbf

6412500 lbf

314420

TFL

SKF

750 mm

1000 mm

250mm

5.5 mm

1386000 lbf

3735000 lbf

1000 rpm

BC2B 326379/HA4

TFL

SKF

800 mm

1260 mm

375mm

11 mm

2880000 lbf

6300000 lbf

BC2-8022/HA1

TFL

SKF

950 mm

1360 mm

420mm

11 mm

3150000 lbf

7537500 lbf

BC2B 326372/HA1

TFL

SKF

1319.5 mm

1720 mm

300mm

7 mm

2812500 lbf

7762500 lbf

Designed for Heavy-Duty Applications

The most fundamental and outstanding characteristic of the double row cylindrical roller bearing is its unparalleled radial load-carrying capacity. Unlike the point contact in ball bearings, cylindrical roller bearings feature line contact between rollers and raceways. This allows the load to be distributed on a much longer contact line, increasing its load capacity.

The double-row design effectively doubles this advantage. With two rows of rollers working in parallel, the double row bearing can withstand extremely heavy radial forces. This design is perfectly suited for heavy industrial applications that demand the utmost strength and durability, such as rolling mills, large gearboxes, mining machinery, and construction equipment. In these scenarios, where immense shock loads and continuous heavy pressure are the norm, our double row cylindrical roller bearings provide stable and reliable support, ensuring equipment operates smoothly even under the most severe conditions and minimizing costly downtime caused by bearing failure.

As a professional cylindrical roller bearing supplier, we ensure every product is built to handle extreme challenges.

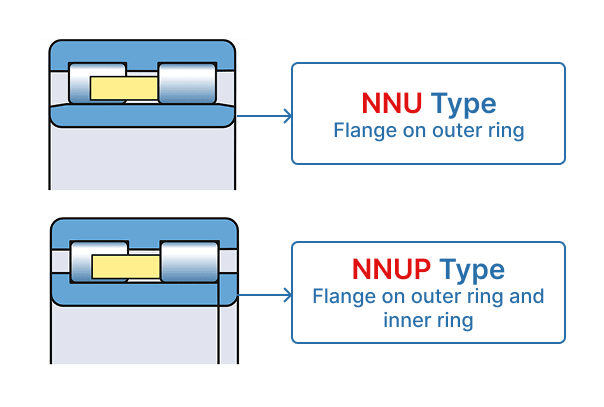

Versatile Designs to Suit Different Mounting Needs (NNU and NNUP Types)

To meet diverse mechanical design requirements, double row cylindrical roller bearings are primarily offered in two classic configurations: NNU and NNUP types.

The main difference between these designs lies in the location of the flanges. In NNU type bearings, the flanges are on the outer ring, while the inner ring has no flanges. Conversely, in NNUP type bearings, the flanges are both on the inner ring and the outer ring. This structural difference determines whether they are “floating ends” or “fixed ends”. The NNU type bearing, with no flange on the inner ring to restrict movement, can move relatively freely and is thus more suitable as a floating end bearing. In contrast, the NNUP type, with flanges on both the inner and outer rings restricting displacement, is more appropriate as a fixed end bearing.

We offer a full range of NN and NNU types, allowing you to choose the most suitable solution based on your specific structural design and assembly requirements.

Reliable Performance with Highly Competitive Cost-Effectiveness

As a professional cylindrical roller bearing supplier, we understand that in the heavy industrial sector, reliability is a non-negotiable baseline, while cost control is key to enhancing competitiveness.

Our double row cylindrical roller bearings are built upon these two core values. We use high-purity GCr15 bearing steel and employ precision forging, heat treatment, and superfinishing grinding processes. This ensures that our products’ dimensional accuracy, hardness, and fatigue life fully meet or exceed industry standards, delivering performance comparable to top-tier brands.

At the same time, through optimized production processes and efficient supply chain management, we are able to offer a highly attractive price point. Choosing us means you don’t have to make a difficult compromise between quality and budget. You get top-performing bearings designed for heavy-load, high-rigidity applications while significantly reducing your total cost of ownership, bringing greater profitability to your projects.

FREQUENTLY ASKED QUESTIONS

What's the difference between a double row cylindrical roller bearing and two single row ones placed side-by-side?

That's an excellent question. While two single row bearings can theoretically be used side-by-side, choosing a single double row bearing is often the better option. The key differences are:

- Space and Rigidity: A single, integral double row cylindrical roller bearing has a more robust outer ring and a more compact structure, providing higher rigidity within a smaller radial footprint.

- Mounting and Alignment: Installing two separate single row bearings requires extremely precise alignment to ensure the load is distributed evenly across both rows of rollers. Any misalignment can lead to stress concentration and premature bearing failure. A double row bearing, as a single unit, has internally guaranteed concentricity and alignment of its two raceways, greatly simplifying installation and ensuring optimal performance.

- Cost-Effectiveness: When considering procurement, installation, and potential alignment issues, selecting a single double row bearing is often the more reliable and, in the long run, more cost-effective solution.

What kind of lubrication do double row cylindrical roller bearings require?

Unlike many pre-lubricated sealed ball bearings, double row cylindrical roller bearings are typically open-type and require on-site lubrication, with stringent lubrication requirements. Proper lubrication is critical to prevent metal-to-metal contact, dissipate heat, and protect against corrosion. There are two main methods:

- Grease Lubrication: Suitable for low-to-medium speed operating conditions. Choose an appropriate grease (based on temperature, speed, and load) and fill the bearing and housing with the correct amount.

- Oil Lubrication: Recommended for high-speed or high-temperature applications. Oil lubrication (such as an oil bath, oil mist, or circulating oil system) provides more effective cooling and lubrication. Many heavy-duty models feature a lubrication groove and holes in the outer ring (suffix W33) to facilitate re-lubrication.

Using the wrong lubricant or improper lubrication is one of the leading causes of failure for these types of bearings.

How can I be sure the bearings I source from you are reliable?

As a responsible cylindrical roller bearing supplier, we ensure product reliability through a multi-layered quality assurance system.

First, we only source high-quality raw materials from strictly vetted suppliers.

Second, our manufacturing facilities adhere to the ISO 9001 quality management system, with strict process controls and in-process inspections at every stage, from heat treatment to final grinding.

Finally, all finished products undergo a final inspection before shipment, which includes a comprehensive check of dimensional tolerances, hardness, appearance, and cleanliness.

We guarantee that every double row cylindrical roller bearing we provide meets international standards, is fully dimensionally interchangeable with products from major brands, and will meet your design requirements in terms of performance. Contact us means choosing a trustworthy, long-term partner that offers both quality and cost advantages.

What payment methods do you offer?

We support multiple payment methods, including Letter of Credit (L/C), bank transfer (T/T), and PayPal, providing convenient options for customers worldwide.