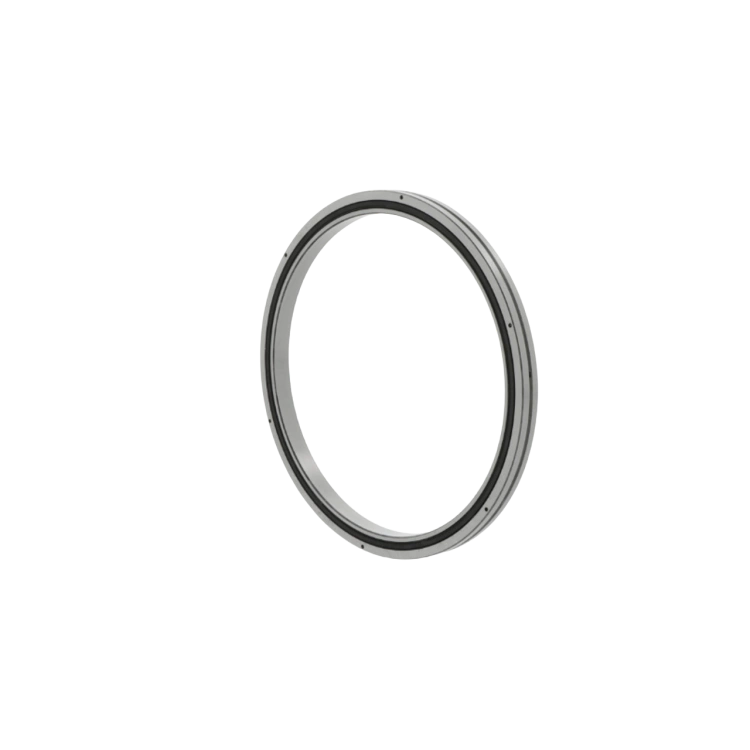

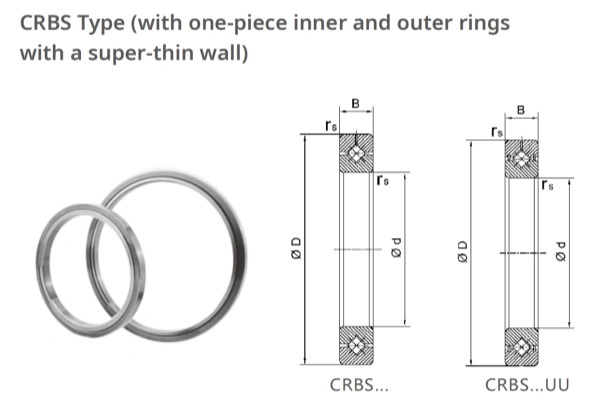

CRBS Crossed Roller Bearings

CRBS: Slim Type Crossed Roller Bearings

Wide Range of Applications: From Robotics to Precision Manufacturing

Because CRBS Crossed Roller Bearings integrate features like an ultra-thin wall, high rigidity, and high precision, they are widely used in a variety of cutting-edge technological fields. In the robotics industry, the CRBS series is a core component of robot joints and robot arms. Their compact design and high load capacity enable robots to achieve precise and smooth movements, greatly improving the efficiency and flexibility of automated production lines. In the medical equipment sector, CRBS bearings are used in surgical robots and medical imaging devices, where their high precision ensures the accuracy and safety of operations.

In addition to robotics and medical equipment, the CRBS series is also commonly used in various precision instruments, such as optical and measuring devices. Their stability and high precision are crucial for ensuring the reliability of measurement results. Furthermore, in the aerospace field, where lightweight design is paramount, CRBS is an ideal choice for aerospace bearings. They are used in satellite solar panel deployment mechanisms and space station mechanical arms, providing reliable rotational support for these critical systems.

Installation Tips and Best Practices

When installing CRBS Crossed Roller Bearings, it is critical to maintain a clean and controlled working environment. All contact surfaces, including shafts, housings, and surrounding components, should be thoroughly cleaned and inspected before installation. Remove any dust, oil, or debris to prevent contamination that could impair the bearing’s performance or shorten its service life.

During installation, ensure accurate alignment of both the inner and outer rings. Proper concentricity and parallelism are vital to avoid uneven load distribution and ensure smooth, high-precision rotation. Misalignment can cause abnormal noise, increased torque, and premature wear.

For CRBS types with filler plugs, double-check that the plug is properly positioned and securely fixed. This ensures that the cross-arranged cylindrical rollers remain accurately aligned during operation and that the bearing retains its high rotational precision.

FREQUENTLY ASKED QUESTIONS