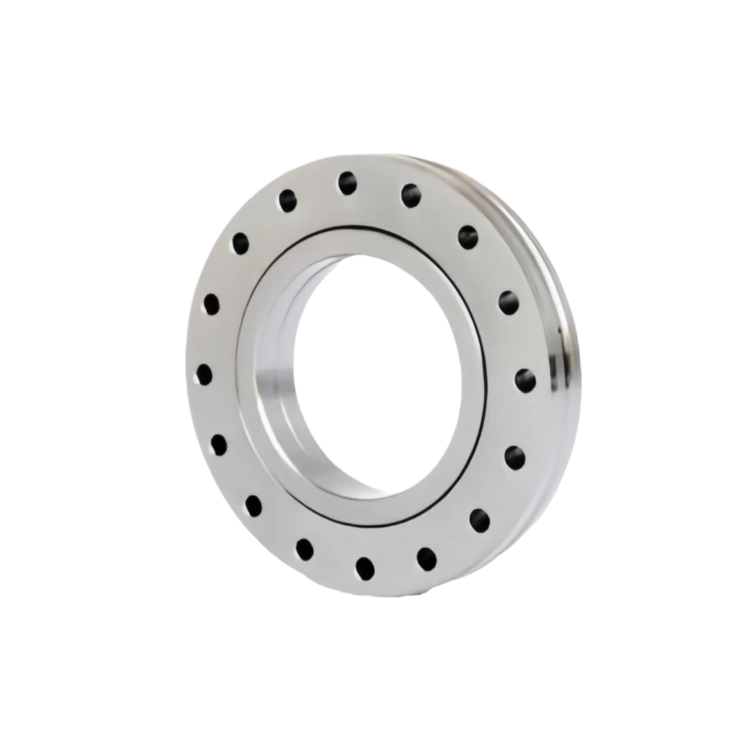

High Rigidity Crossed Roller Bearings

Crossed Roller Bearings feature a compact structure with rollers arranged in a crossed pattern. This allows them to handle loads in multiple directions simultaneously. They are ideal for applications with stringent requirements for both space and performance, such as robotic joints, medical device rotations, and aerospace components.

Home / Product / Roller Bearings / Crossed Roller Bearings

Why Choose TFL?

Our products are made from premium materials using advanced manufacturing processes to ensure superior performance and long service life. We offer a wide range of series, such as RU, CRBF, CRBH, SX, XV, RB, RA, and others, to meet the specific needs of different customers.

-

Top

Product Category

Application

FAQ

Our Process

Hot Products

Support

Roller Bearings Category

Roller Bearings Category

The Unique Design and Advantages of Crossed Roller Bearings

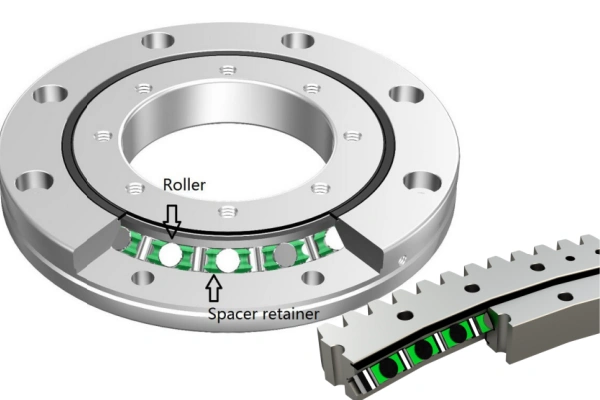

The core design of a crossed roller bearing lies in its roller arrangement. It places cylindrical or crossed tapered roller bearings at a 90-degree angle between V-groove raceways. This design allows a single bearing to handle radial, axial, and moment loads simultaneously. Compared to two separate traditional bearings, this design saves significant space and simplifies the installation process. Its high rigidity and high precision characteristics make it ideal for many advanced applications. For instance, in industrial robots, crossed roller bearings provide the stability and accuracy required for joints.

Main Applications of Crossed Roller Bearings

Due to their high precision and high rigidity, crossed roller bearings are widely used in several key areas. One of the most common applications is in robot bearings. In robot joints, bases, and end effectors, they provide the necessary precise motion and load capacity. Furthermore, they are crucial components in precision machine tools, rotary table bearings, and medical equipment. In semiconductor manufacturing equipment, they ensure smooth and precise wafer handling. These high precision bearings play a vital role in any application that requires precise control, stability, and reliability.

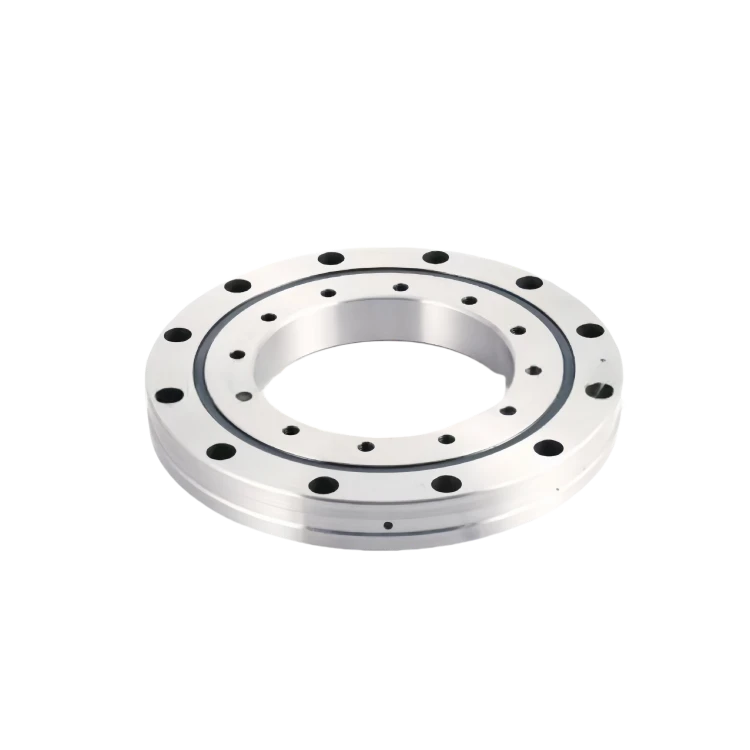

Classifications and Types of Crossed Roller Bearings

Crossed roller bearings come in various structures and series to suit different application needs. Some common series include:

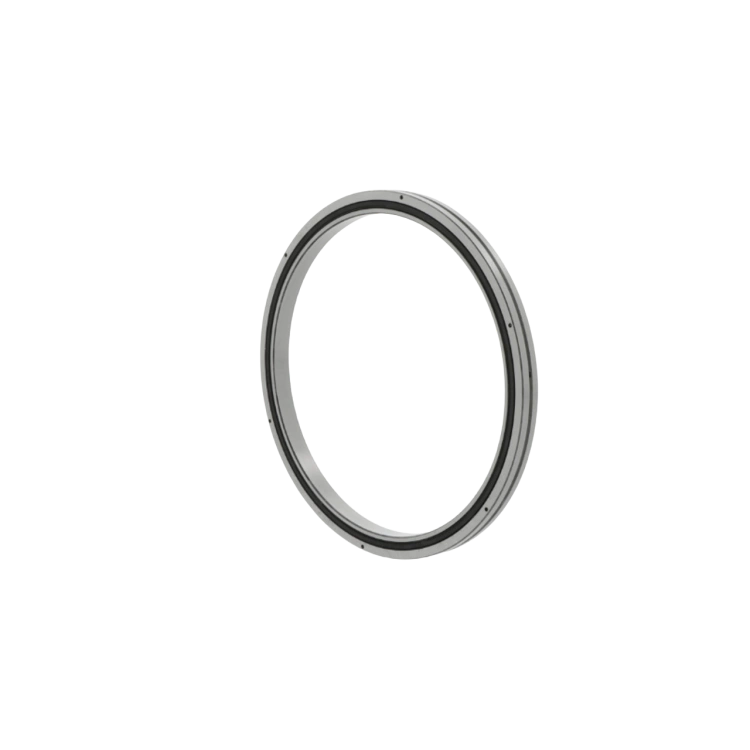

- RB Series and RA Series: These are basic, most commonly used types, often for applications requiring high rigidity and high precision.

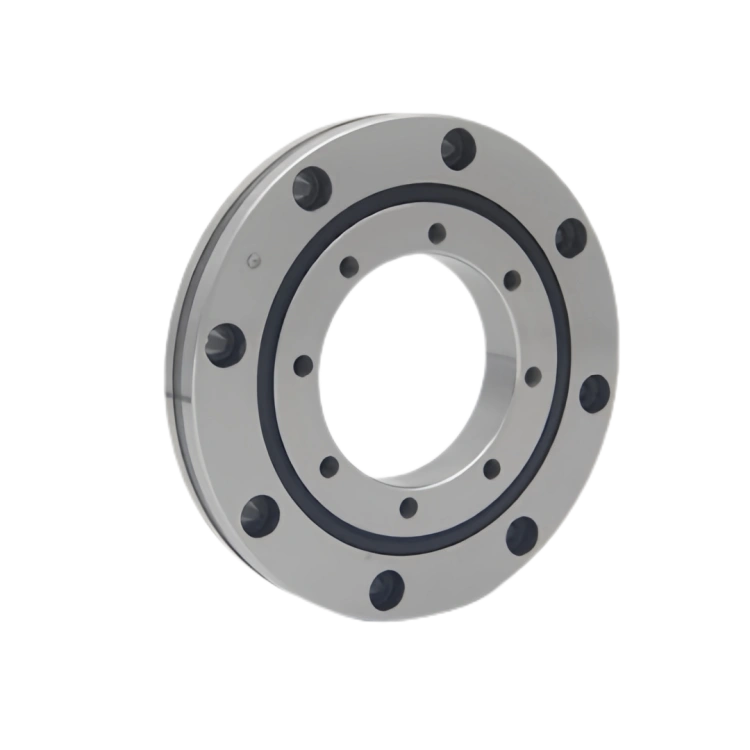

- CRBF Series and CRBH Series: These are flanged bearings, which can be easily mounted directly onto equipment without additional fixtures.

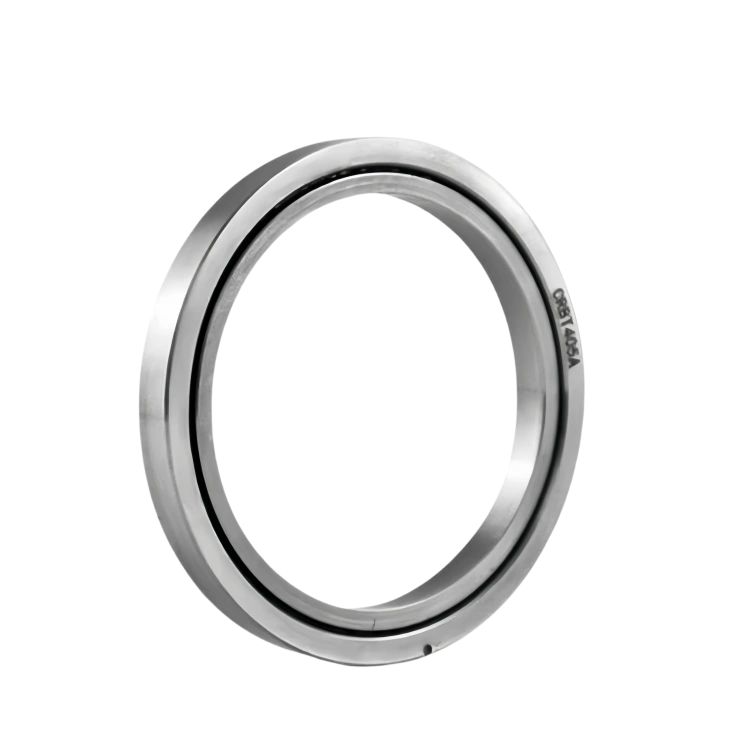

- RU Series: This type features an integrated inner and outer ring design, simplifying installation by not requiring additional spacers.

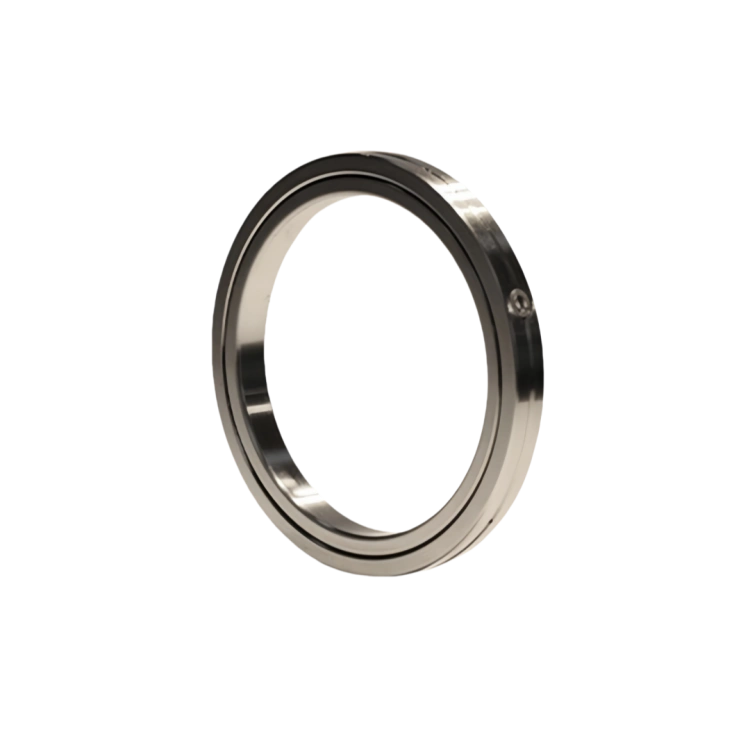

- SX Series and XV Series: These are thin section bearings designed for applications where space is limited but high precision is still required. Each type of crossed roller bearing is carefully engineered to provide optimal performance in its specific application.

APPLICATION AREA

Medical Bearings

Medical Bearings The Medical Technology sector develops advanced equipment for diagnostics, treatment,

Marine Bearings

Marine Bearings The Marine Industry operates in one of the planet’s most demanding environments.

Agricultural Bearings

Agricultural Bearings The Agricultural Machinery sector is the backbone of global food production, uti

Heavy Equipment (Construction & Mining)

Heavy-Duty Bearings for Construction and Mining Equipment like excavators, bulldozers, loaders, cranes

INTERCHANGEABLE BRANDS

TFL Bearings: High quality bearings, an ideal choice to replace SKF and FAG.

WHY CHOOSE TFL

QUALITY

Market-proven with over 28 million bearings successfully delivered, and certified under multiple quality management systems, including ISO 9001.

PRICE

By integrating and leveraging China’s robust raw material supply chain, TFL is able to strictly control production costs, thereby offering highly competitive product prices.

FAST DELIVERY

With a vast inventory of over a million bearings, TFL offers solid assurance for your procurement needs. Common bearing models are ready for dispatch within just 48 hours.

FREQUENTLY ASKED QUESTIONS

What is a crossed roller bearing? How is it different from a conventional bearing?

A crossed roller bearing is a type of high precision bearing that is unique because its rollers are arranged at a 90-degree angle to each other on V-groove raceways. Unlike conventional bearings that can only handle a single type of load (either radial or axial), a crossed roller bearing can handle loads from all directions simultaneously, including radial force, axial force, and moment loads. This makes its structure more compact while providing higher rigidity and rotational accuracy. It is an ideal choice for applications requiring precise motion control, such as robot bearings, rotary table bearings, and precision machine tools.

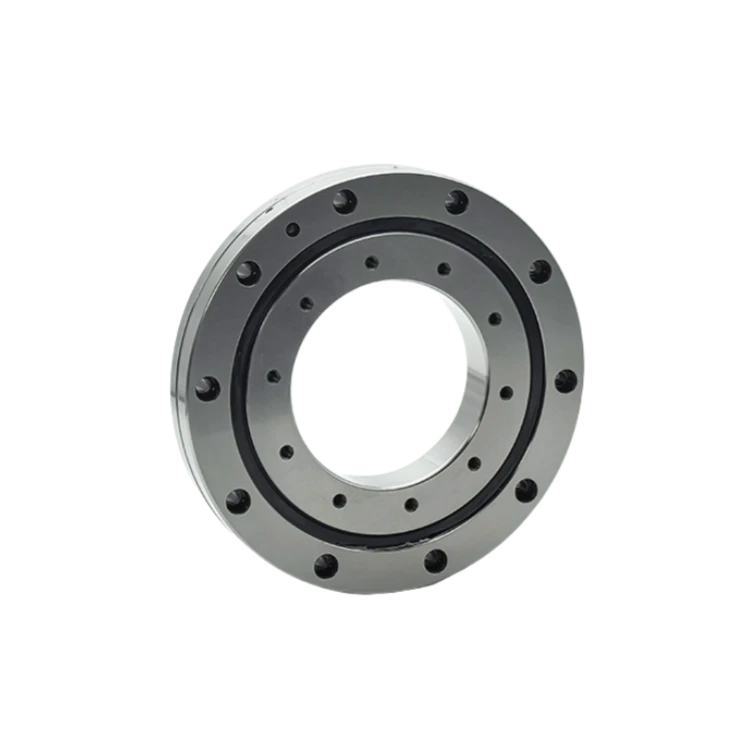

Why are crossed roller bearings referred to as "high precision bearings"?

Crossed roller bearings are called high precision bearings because their design and manufacturing process are aimed at achieving extremely high rotational accuracy and stability. The precise arrangement of rollers and the use of spacers minimize friction and motion errors. Furthermore, crossed roller bearings have very high rigidity, which means they undergo minimal deformation under load and can maintain a stable geometric position. These characteristics allow them to meet the stringent accuracy requirements of applications such as robot bearings and precision machine tools.

What series of crossed roller bearings does TFL Bearings offer? How do I choose the right one?

TFL Bearings offers a variety of crossed roller bearings series to suit different applications, such as RU, CRBF, CRBH, RB, RA, SX, and XV series. Choosing the right type depends on your specific application requirements, including required load capacity, installation space, precision grade, and mounting method. For example, if you need a flanged bearing that can be bolted directly, the CRBF or CRBH series might be a better choice. If you need a thin section bearing, you could consider the SX or XV series. It is recommended that you contact our technical team with your design requirements to get expert guidance.

What is the role of a crossed roller bearing in an industrial robot?

In an industrial robot, crossed roller bearings play a crucial role. A robot's joints need to rotate with high precision and stability while withstanding various forces from gravity, loads, and motion. The high rigidity and high precision characteristics of a crossed roller bearing allow it to meet these demanding requirements. It ensures that the robot can achieve accurate positioning and repeatability when performing tasks, significantly improving its overall performance. Crossed roller bearings are indispensable in critical parts like robot joints, rotary table bearings, and end effectors.