Home / Product / Electrically Insulated Bearings / Electrically Insulated Deep Groove Ball Bearings / FAG Current Insulated Deep Groove Ball Bearings

FAG Current Insulated Deep Groove Ball Bearings

FAG Current Insulated Deep Groove Ball Bearings are high-quality solutions specifically designed for high-voltage operating environments such as motors, generators, and variable frequency drive systems. These bearings feature an aluminum oxide ceramic coating on either the inner or outer ring surface, providing excellent electrical insulation performance (capable of withstanding up to 1000V DC voltage), effectively preventing current from passing through the bearings and causing electrical erosion damage and premature failure.

Loading...

Total 178 Results

Model

Insulating Coating Types

Bore Diameter

Outside Diameter

Width

Net Weight

Basic Dynamic Load Rating

Basic Static Load Rating

Breakdown Voltage (DC)

Electrical Resistance

6309-J20AA-C3

Outer ring ceramic coated

45.0 mm

100.0 mm

25.0 mm

0.802 kg

56.0 kN

31.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6309-J20AA-C4

Outer ring ceramic coated

45.0 mm

100.0 mm

25.0 mm

0.83 kg

56.0 kN

31.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6309-J20AB-C4

Outer ring ceramic coated

45.0 mm

100.0 mm

25.0 mm

0.813 kg

56.0 kN

31.5 kN

≤500 V

50MΩ (Dry); 10MΩ (Damp)

6310-J20AA-C3

Outer ring ceramic coated

50.0 mm

110.0 mm

27.0 mm

1.09 kg

68.0 kN

38.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6310-M-J20AA-C3

Outer ring ceramic coated

50.0 mm

110.0 mm

27.0 mm

1.31 kg

68.0 kN

38.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6311-J20AA-C3

Outer ring ceramic coated

55.0 mm

120.0 mm

29.0 mm

1.37 kg

83.0 kN

47.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6311-M-J20AA-C3

Outer ring ceramic coated

55.0 mm

120.0 mm

29.0 mm

1.616 kg

83.0 kN

47.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6311-M-J20AA-C4

Outer ring ceramic coated

55.0 mm

120.0 mm

29.0 mm

1.616 kg

83.0 kN

47.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6212-M-J20AA-C3

Outer ring ceramic coated

60.0 mm

110.0 mm

22.0 mm

0.92 kg

57.0 kN

36.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6212-M-J20AA-C4

Outer ring ceramic coated

60.0 mm

110.0 mm

22.0 mm

0.92 kg

57.0 kN

36.5 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6312-J20AA-C3

Outer ring ceramic coated

60.0 mm

130.0 mm

31.0 mm

1.65 kg

89.0 kN

52.0 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6312-J20AA-C4

Outer ring ceramic coated

60.0 mm

130.0 mm

31.0 mm

1.65 kg

89.0 kN

52.0 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

6312-J20AB-C3

Outer ring ceramic coated

60.0 mm

130.0 mm

31.0 mm

1.64 kg

89.0 kN

52.0 kN

≤500 V

50MΩ (Dry); 10MΩ (Damp)

6312-M-J20AA-C3

Outer ring ceramic coated

60.0 mm

130.0 mm

31.0 mm

2 kg

89.0 kN

52.0 kN

≤3000 V

50MΩ (Dry); 10MΩ (Damp)

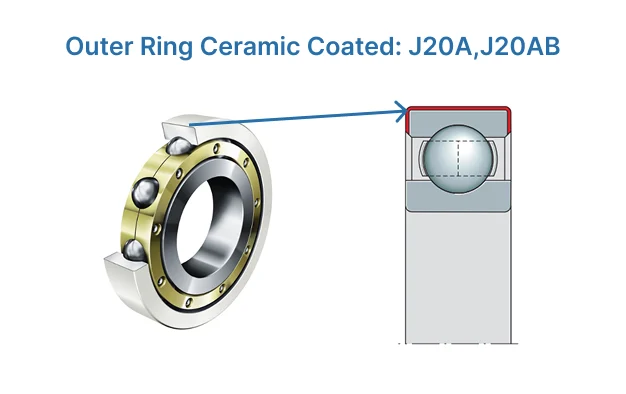

Ceramic Coatings Offer Unparalleled Electrical Insulation Performance

The electrically insulated bearings we produce can serve as a high-performance alternative to FAG electrically insulated bearings. The core electrical insulation capability of these bearings comes from a precise layer of aluminum oxide (Al₂O₃) ceramic coating on the surface.

This coating is formed through an advanced plasma spray process, creating a strong insulating barrier. The coating has undergone quality inspection and guarantees a dielectric strength of at least 1000 VDC (J20AA, J20C) or 500 VDC (J20AB). This coating on FAG bearings can prevent severe damage caused by electrical corrosion or erosion on the raceways and rolling elements. For engineers designing or maintaining high-power motors and generators, this feature is not just a technical parameter-it is the first line of defense to ensure long-term stable operation of equipment and prevent catastrophic current-induced bearing failure.

Seamlessly Interchangeable With Fag Insulated Bearings

It is well known that the smooth operation of equipment depends on the compatibility and convenience of components in each part. We produce electrically insulated deep groove ball bearings that are exactly the same in size and performance as FAG’s similar products.

This means that these bearings are designed for seamless replacement, and you don’t need to make any modifications to your existing bearing housings or shafts. Whether you are replacing a specific part number like 6320-M-J20AA-C3 or looking for a source for a new project, we are committed to finding the exact match for you. This one-to-one interchangeability will greatly simplify your procurement process and eliminate technical challenges for your maintenance team.

Not Only Excellent Insulation Performance

The performance of electrically insulated bearings is not only determined by the quality of the insulating coating. As they are essentially bearing components, the quality level of the bearings themselves is also extremely important for the equipment.

Among the alternatives to FAG electrically insulated deep groove ball bearings that we produce, all the bearings maintain the characteristics of FAG deep groove ball bearings and are consistent with FAG deep groove ball bearings in terms of load capacity, rotational speed, and bearing life. We provide reliable and high-speed electrically insulated deep groove ball bearings for your equipment.

FREQUENTLY ASKED QUESTIONS

Are your bearings genuine FAG products? How can you use the "FAG" name?

This is an important and fair question.

To be perfectly clear: we sell high-quality alternatives, not original FAG products. Our bearings are designed as direct, drop-in replacements for the FAG current insulated bearing series. We use the "FAG" name and part numbers for reference and cross-referencing purposes only. This helps engineers and buyers who are familiar with FAG specifications to easily identify and source our dimensionally and functionally equivalent, yet more cost-effective, solutions. Our goal is to provide a transparent and efficient way for you to find a reliable alternative without compromising on performance.

Does the ceramic coating affect the bearing's load capacity or dimensions?

No. The ceramic coating is very thin (typically around 100 micrometers) and is applied to the non-critical outer surface of the outer ring. The fundamental boundary dimensions of the bearing—the bore diameter, outer diameter, and width—remain exactly the same as a standard, non-insulated bearing of the same size. Therefore, the bearing fits into the same housing bore. Furthermore, the load-carrying capacity (both dynamic and static load ratings) is determined by the internal geometry and the steel components, which are identical to their standard counterparts. You gain the benefit of electrical protection with no compromise on mechanical performance or physical fit.

What do the coating codes of FAG bearings respectively mean?

The coating codes of FAG bearings are mainly used to indicate the type and characteristics of the coating on the bearing surface. The common coating codes and their meanings are as follows:

- J20AA: J20AA indicates that the outer ring is coated with an electrically insulating coating, usually paired with a copper cage, which can play an insulating role and prevent shaft current from damaging the bearing.

- J20AB: J20AB indicates that an additional layer of alumina coating is added to the outer ring, which can withstand up to 500 volts of direct current.

- J20C: It indicates that the inner ring of the bearing is coated with an electrically insulating coating. By applying an insulating coating on the inner ring surface of the bearing, the eddy current effect can be avoided, preventing damage to the grease and rolling elements, raceways caused by current.

How can I obtain a quotation for the alternative of FAG current insulated bearings?

It's very simple to get a quote. The most convenient way is to provide us with the complete FAG part number of the item you need to replace (for example, "FAG 6320-M-J20AA-C3"). You can enter this number in the search bar on our website to find our direct equivalent product, and submit the information through the inquiry box on the right side.

Our technical sales team will promptly reply with a competitive quote for our high-quality alternatives, which usually offer better prices and delivery times. If you don't have the part number, you can also contact us, and we can help you select the correct bearing based on the technical requirements of your application.