Improving Screw Compressor Reliability: High-Performance Bearing Solutions

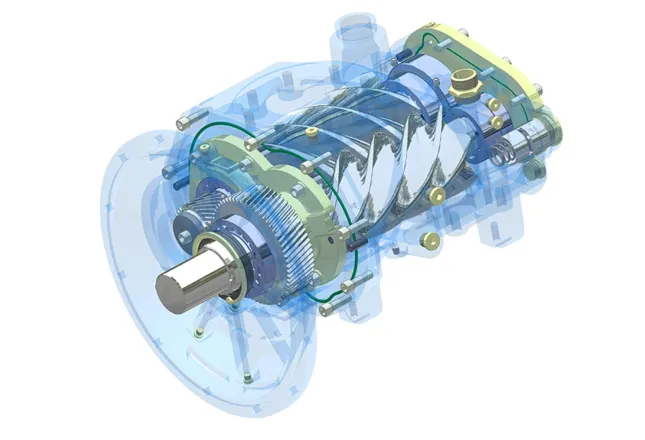

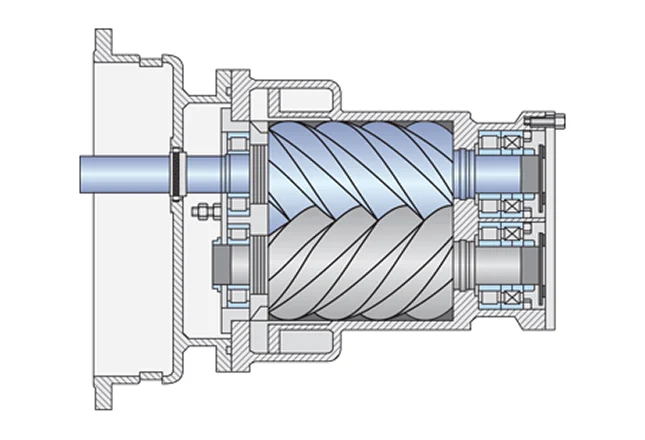

A screw compressor, also known as a helical-lobe compressor, is a type of rotary positive displacement machine. It functions by compressing gas between two precision-engineered, intermeshing helical rotors. Valued for their smooth operation, durability, and high efficiency, screw compressors are critical equipment in industrial air systems, process gas compression, refrigeration, and HVAC.

The heart of the compressor—the rotors—operates under extreme conditions: high speeds, elevated temperatures, significant pressure, and complex combined axial and radial loads. Even a minor bearing failure can disrupt rotor clearances, drastically reduce efficiency, and lead to catastrophic events like rotor seizure, resulting in costly downtime and repairs.

To meet these demanding challenges, TFL offers a complete range of high-performance bearing solutions engineered specifically for screw compressors. Our portfolio, featuring high-precision angular contact ball bearings and cylindrical roller bearings, is designed to withstand high-speed, heavy-load, and high-temperature environments, ensuring the long-term reliability of the compressor’s core assembly.

By implementing TFL bearing solutions, you gain:

- Extended Equipment Uptime: Superior load capacity and wear resistance significantly reduce unplanned downtime.

- Improved Energy Efficiency: Optimized internal geometry and low-friction designs lower energy consumption.

- Reduced Maintenance Costs: Exceptional service life minimizes the need for frequent maintenance and replacement.

- Optimized Total Cost of Ownership (TCO): Maximizing reliability and efficiency delivers the best long-term value.

Do you need our assistance?

If you'd like one of our specialists to contact you to discuss your specific needs then please click here.

Machine Tool

Electric Motors

Metallurgical Industry

Industrial Pumps

Compressors

Food & Beverage Machinery

Plup and Paper

Plastic Machinery

Discover how TFL BEARINGS help leading international companies boost equipment performance and efficiency.

Common Bearing Problems in Screw Compressors

Bearing failures in screw compressors are diverse, often resulting from a complex mix of design, lubrication, installation, and operating factors. Accurate diagnosis is the first step toward an effective solution. This table outlines the most frequent failure modes in the industry.

Common Problems List

| Failure Mode | Observable Signs | Primary Causes |

| Fatigue Spalling | Flaking or pitting on raceway or rolling element surfaces, which grows over time. |

|

| Abrasive Wear | Dull, unpolished surfaces on raceways and rolling elements; uniform material loss. |

|

| Cage Damage | Deformed, fractured, or heavily worn cage. |

|

| Creep | Relative slippage between the bearing ring and the shaft or housing, causing polished or discolored mating surfaces. |

|

Application Analysis for Screw Compressors

For the complex and demanding operating conditions in screw compressors, TFL provides proven, high-performance bearing solutions for each critical application point:

Application 1: The Drive End (Fixed End) Bearing Set

- Operating Conditions: This critical position supports high radial loads from the drive system and heavy, bi-directional axial thrust generated by gas compression. It requires exceptional rigidity and precision to maintain the correct axial position of the rotor and control the critical discharge clearance.

- TFL Solution: Matched Pair of Angular Contact Ball Bearings

We recommend a back-to-back (DB) or face-to-face (DF) arrangement of our 7200 or 7300 series bearings.- High Axial Load Capacity: A 40° contact angle is optimized to accommodate heavy axial forces, reliably managing the thrust created during compression.

- Excellent System Rigidity: The preloaded pair configuration provides superior system stiffness, preventing axial shaft movement and ensuring precise rotor positioning under all loads.

- High-Speed Performance: Precision manufacturing and optimized internal design ensure smooth, low-vibration operation at the high rotational speeds typical of screw compressors.

Application 2: The Non-Drive End (Floating End) Bearing

- Operating Conditions: This position primarily handles radial loads. The key challenge is to accommodate the axial thermal expansion and contraction of the rotor during operation. Restricting this movement would induce high internal stresses, leading to premature bearing failure.

- TFL Solution: High-Capacity Cylindrical Roller Bearing

Our recommendation is an NU or N-type cylindrical roller bearing.- Accommodates Thermal Expansion: The design of an NU-type bearing (with two flanges on the outer ring and no flanges on the inner ring) allows for relative axial displacement between the rings. This perfectly compensates for rotor thermal expansion, eliminating the risk of induced axial stress.

- High Radial Load Capacity: The line contact between rollers and raceways provides outstanding radial stiffness and load-carrying capacity in a compact space, ensuring stable rotor support.

Core Product Overview: Quick Reference for Screw Compressor Bearings

| Application Part | Bearing Type | Common Part Numbers (Examples) | Key Features |

| Drive End (Fixed) | Angular Contact Ball Bearing | 7318 B-MP | 40° contact angle, high axial capacity, high rigidity, used in pairs. |

| Non-Drive End (Floating) | Cylindrical Roller Bearing | High radial capacity, accommodates axial displacement, compensates for thermal expansion. | |

| High-Speed/Low-Noise | Hybrid Ceramic Bearing | HC 7214 E.TPA HC 7316 E.TPA | Higher speed limit, electrical insulation properties, lower heat generation. |

| Harsh Media | Special Material Bearings | 7218 B.TPA NU 318 E.TVH | Excellent chemical resistance, suitable for poor lubrication conditions. |

Note: Final bearing selection depends on specific load, speed, and dimensional requirements. Please consult a TFL application engineer for a precise recommendation.

TFL Boosting Screw Compressor Rotor Reliability and Cutting Unplanned Downtime by 50%!

TFL offers custom bearing solutions for screw compressors to combat failures from high speed, heat, and loads. Their bearings use optimized designs and special materials to extend service life and boost reliability.

Investing in Reliability is an Investment in Productivity

Within the total operating cost of a screw compressor, the initial price of a bearing is negligible. Yet, its performance is critical to the efficiency, reliability, and service life of the entire system. Choosing TFL high-performance bearings—engineered specifically to handle heavy axial loads, high speeds, and extreme operating temperatures—is a strategic investment in lowering your Total Cost of Ownership (TCO). This approach not only prevents catastrophic failures and unscheduled downtime but also maintains optimal rotor clearance, ensuring peak energy efficiency and consistent output.