In modern mechanical design, engineers are often challenged to balance load capacity, space constraints, and efficiency. Bearings play a critical role in meeting these requirements, especially in systems where compact size and high load support are essential. Among the various bearing types available, needle roller bearings are uniquely designed to handle high radial loads while occupying minimal space. Understanding what a needle roller bearing is and how it functions helps engineers and maintenance professionals make informed decisions in compact and high-performance applications.

What Is a Needle Roller Bearing

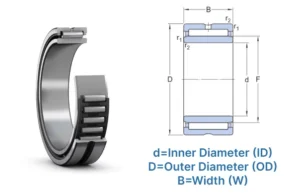

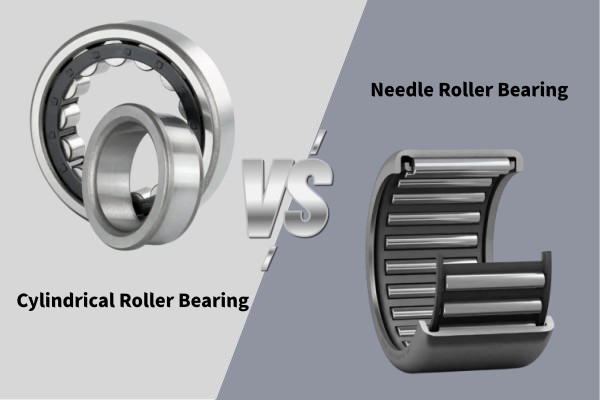

A needle roller bearing is a type of roller bearing that uses long, thin cylindrical rollers known as needle rollers. These rollers have a much smaller diameter relative to their length compared to conventional cylindrical roller bearings. This geometry allows needle roller bearings to provide a high load-carrying capacity within a very compact radial envelope.

Unlike ball bearings, which rely on point contact, needle roller bearings operate with line contact between the rollers and raceways. This line contact significantly increases their ability to support radial loads, making them suitable for applications where space is limited but load demands remain high.

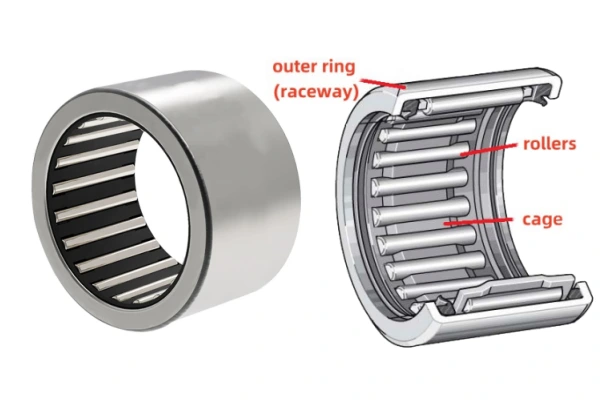

Basic Construction and Design Characteristics

The defining feature of a needle roller bearing is the slender shape of its rolling elements. Needle rollers are typically several times longer than their diameter, which allows more rollers to be packed into a given space. This design increases the contact area between rollers and raceways, enhancing load distribution.

Needle roller bearings may be supplied with or without an inner ring. In designs without an inner ring, the shaft itself serves as the raceway, provided it is hardened and ground to appropriate specifications. Bearings with an inner ring are used when the shaft material or surface finish does not meet raceway requirements.

Cage design is another important aspect. The cage guides and separates the needle rollers, ensuring smooth rotation and preventing roller skewing under load. Different cage materials are used depending on speed, temperature, and lubrication conditions.

How Needle Roller Bearings Work

Needle roller bearings reduce friction by replacing sliding motion with rolling motion between the shaft and housing. As the shaft rotates, the needle rollers roll along the raceway surfaces, supporting radial loads while minimizing energy loss.

Because of their small diameter, needle rollers can accommodate a large number of rolling elements within a limited space. This allows the bearing to distribute loads efficiently across multiple contact points, reducing stress on individual rollers and improving durability.

Load Capacity and Performance

One of the primary advantages of needle roller bearings is their high radial load capacity relative to size. Although they are compact, their line contact design enables them to handle loads that would typically require larger bearing types.

However, needle roller bearings are generally not designed to support significant axial loads. In applications where axial forces are present, additional components such as thrust bearings or flanges are often required. Understanding this limitation is critical when selecting needle roller bearings for real-world applications.

Types of Needle Roller Bearings

Needle roller bearings are available in several configurations to suit different application requirements. Common types include drawn cup needle roller bearings, machined ring needle roller bearings, and needle roller and cage assemblies.

Drawn cup needle roller bearings feature a thin outer shell that is formed from sheet steel. These bearings are lightweight and economical, making them ideal for high-volume applications. Machined ring needle roller bearings, on the other hand, offer higher rigidity and accuracy and are used in more demanding industrial environments.

Needle roller and cage assemblies consist only of rollers and a cage, without inner or outer rings. These assemblies are used where raceways are integrated directly into the shaft and housing.

Space Efficiency in Mechanical Design

Space efficiency is one of the key reasons engineers choose needle roller bearings. In compact machinery, such as automotive transmissions or portable equipment, radial space is often limited. Needle roller bearings provide high load support without increasing overall system size.

This compact design allows for lighter and more efficient machines while maintaining structural integrity. In many cases, replacing a larger bearing type with a needle roller bearing enables designers to reduce weight and material usage.

Common Applications of Needle Roller Bearings

Needle roller bearings are widely used across industries where space constraints and load demands coexist. In the automotive sector, they are commonly found in transmissions, gearboxes, universal joints, and engine components. Their compact size and durability make them well suited for high-volume automotive production.

In industrial machinery, needle roller bearings are used in compressors, pumps, power tools, and textile equipment. They are also found in agricultural machinery, construction equipment, and material handling systems. In each of these applications, the ability to handle high radial loads in limited space is a significant advantage.

Advantages of Needle Roller Bearings

The primary advantage of needle roller bearings is their high load capacity relative to size. This makes them ideal for applications where space savings are critical. Their design also offers good rigidity, which helps maintain alignment and reduce vibration.

Another advantage is design flexibility. With multiple configurations available, needle roller bearings can be adapted to a wide range of shaft and housing arrangements. They also perform well in moderate to high-speed applications when properly lubricated.

Additionally, needle roller bearings often contribute to improved efficiency by reducing friction losses compared to plain bearings, especially under higher loads.

Limitations and Design Considerations

Despite their advantages, needle roller bearings have certain limitations. Their ability to handle axial loads is limited, and they require precise raceway surfaces to perform effectively. Shafts used as raceways must be hardened and ground to tight tolerances.

Lubrication is another important consideration. Because of the high contact pressures involved, proper lubrication is essential to prevent wear and overheating. Inadequate lubrication can significantly reduce bearing life.

Designers must also consider operating speed. While needle roller bearings can operate at moderate to high speeds, excessive speed combined with heavy loads may lead to increased heat generation.

Importance of Proper Installation

Correct installation is critical for needle roller bearing performance. Misalignment, improper fits, or damage during installation can compromise bearing function and lead to premature failure. Care must be taken to ensure that bearings are installed squarely and that raceway surfaces are clean and undamaged.

In applications without an inner ring, particular attention must be given to shaft preparation. Surface hardness, finish, and dimensional accuracy directly influence bearing performance and longevity.

Maintenance and Service Life

When properly selected and maintained, needle roller bearings offer long service life and reliable performance. Regular maintenance practices such as lubrication monitoring, contamination control, and condition inspection help extend bearing life.

In critical systems, condition monitoring techniques such as vibration analysis can be used to detect early signs of wear or damage. This proactive approach minimizes downtime and reduces the risk of catastrophic failure.

Role of Technical Guidance in Bearing Selection

Selecting the right needle roller bearing requires a clear understanding of load conditions, space constraints, and operating environment. Technical guidance from reliable sources helps engineers avoid common selection errors and ensures optimal performance.

Detailed explanations of needle roller bearing features, applications, and advantages, such as those provided by SDTFL Bearing, support informed decision-making and effective application design.

Comparison With Other Bearing Types

Compared to ball bearings, needle roller bearings offer higher radial load capacity but lower axial load capability. Compared to cylindrical roller bearings, they provide similar load support in a much smaller radial space, though often with lower speed limits.

These trade-offs highlight the importance of application-specific evaluation. Needle roller bearings excel where compactness and load capacity are prioritized over axial load handling or extreme speed performance.

Conclusion

A needle roller bearing is a compact yet powerful solution for supporting high radial loads in space-constrained mechanical systems. Its unique design, featuring long and slender rollers, allows efficient load distribution and reliable performance across a wide range of applications. From automotive transmissions to industrial machinery, needle roller bearings enable efficient and compact designs without sacrificing durability.

Understanding what a needle roller bearing is, how it works, and where it performs best allows engineers and maintenance professionals to select the right bearing for their needs. As mechanical systems continue to evolve toward higher efficiency and smaller footprints, needle roller bearings will remain an essential component in modern engineering.

Tight on Space but Need High Load Capacity?

Designing compact machinery requires precision. Needle Roller Bearings are the ultimate solution for balancing high radial loads with minimal spatial requirements.

At SDTFL Bearings, we offer a wide range of needle roller assemblies, drawn cup, and machined ring designs tailored for automotive and industrial applications.

View Needle Roller Catalog

Consult Our Engineers

Direct Contact: 📧 info@sdtflbearing.com | 📞 +86 15806631151