In today’s global market, brands face ever-increasing demands for motor performance. Low noise, high efficiency, reliability, and cost-effectiveness are no longer just features—they are competitive essentials.

We understand that a high-quality motor bearing is a silent but powerful component that can transform your product. It not only significantly reduces noise for a superior user experience but also extends motor life, building a reputation for excellence. By leveraging our efficient and direct supply chain, you can easily source premium deep groove ball bearings from China. We ensure that every batch meets stringent quality standards, providing you with consistent and reliable performance.

Motor Bearing Noise and Its Impact

Normal vs. Fault-Induced Noise

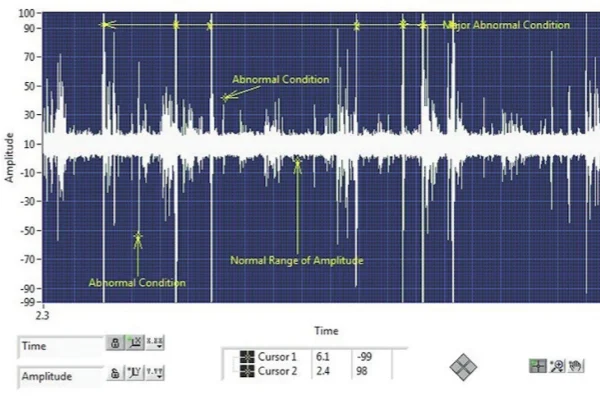

Motor noise significantly impacts both the performance and longevity of electric motors. A key contributor to operational quietness and efficiency lies in the quality of deep groove ball bearings. High-quality bearings generate low-energy sounds primarily within the ultrasonic frequency range, rendering them imperceptible to the human ear and ensuring smooth motor operation. This contributes to enhanced overall motor performance and reduced energy consumption.

However, the presence of bearing faults dramatically alters the acoustic signature. Imperfections on the raceways or rolling elements induce characteristic vibrations at specific fault frequencies, including outer race fault frequency (ORFF), inner race fault frequency (IRFF), rolling element fault frequency (REFF), and cage fault frequency (CFF). As these faults develop, the noise intensity increases, shifting into the audible 2-6 kHz range. This escalation in noise directly correlates with degraded motor performance and increased energy consumption. Further progression of bearing wear is indicated by the appearance of sidebands adjacent to these fault frequencies.

For a deeper dive into related topics, we recommend the following articles:

- Why Are Your Ball Bearings Making Noise?

- Stop Worrying About Motor Bearing Noise: A Guide to Normal Sounds

- Reducing Electric Motor Noise: A Bearing-Centric Approach from Design to Application

Model-based fault diagnosis methods help brands find bearing problems early. These methods use electrical data from the motor’s input and output. They do not need extra sensors. They can find small noise changes before big issues start. This helps deep groove ball bearings last longer. It also keeps motors working well and saves energy.

Why Brands Value Noise Reduction

Brands want motors to be quiet. Quiet motors work better and use less energy. Customers trust products that use deep groove ball bearings for quiet running. Low noise means the motor is made well. It also means the bearings will last longer.

Deep groove ball bearings help motors work with less rubbing. This makes them more efficient and saves energy. Brands save money because motors break less often. Products with quiet motors are easier to sell. They help brands build a good name for quality and trust.

- Deep groove ball bearings help electric motors in many ways:

- They lower noise and shaking.

- They boost performance and save energy.

- They help motors last longer.

- They cut down on repair costs.

Brands pick deep groove ball bearings for motors because they want the best performance, high efficiency, and quiet running. These bearings help products meet tough rules and keep customers happy.

TFL’s Motor Bearings: Competitive Advantages

Cost Control Through China’s Supply Chain

TFL’s exceptional motor bearings empower global brands to thrive in competitive markets. We maintain stringent control over every stage of the process, from design to delivery, all managed expertly within China.

Vertical Integration & Cost Efficiency:

TFL proudly owns and operates its state-of-the-art factories, fostering close collaborations with experienced local suppliers in China. This unique vertical integration model allows us to leverage China’s robust supply chain advantages, effectively managing production costs. As a result, we deliver deep groove ball bearings that offer both superior quality and compelling cost-effectiveness to our clients.

Rigorous Quality Assurance:

Quality is the cornerstone of TFL’s operations. Our dedicated team implements meticulous quality checks at every phase of production. From the careful selection of raw materials and vigilant monitoring of the manufacturing process to comprehensive performance testing of finished bearings, each step is rigorously scrutinized. This unwavering commitment ensures that every deep groove ball bearing meets our exacting standards, earning TFL the trust of global brands for consistent product excellence.

Commitment to Sustainability:

TFL’s comprehensive control over its supply chain also underscores our strong commitment to environmental responsibility. We actively work to optimize energy efficiency and minimize waste generation throughout our operations. When selecting local suppliers in China, we prioritize partners who share our dedication to environmental stewardship. By collaborating with TFL, brands not only receive premium products but also contribute to their own sustainability goals, offering more environmentally conscious choices to their customers.

Quality and Durability for Brands

Brands want deep groove ball bearings that last a long time. TFL’s motor bearings are known for being strong and high quality. The company uses new tools in China to make bearings very exact. Every bearing gets checked carefully.

- TFL uses special machines and lasers to measure very small details.

- They check the materials and sizes to make sure everything is right.

They look at the surface to make sure it is smooth and strong.

They test how long bearings last and use cameras to spot problems early.

They use heat and metal checks to make bearings hard and tough.

Bearings meet top standards like ISO P4 or ABEC 7 for best fit and trust.

Quality checks include tests for friction, heat, and how long they last in real use.

These steps make deep groove ball bearings that do not wear out fast. Motors run better and last longer. Brands have fewer problems and breakdowns. TFL’s quality checks make sure every bearing is top quality. This also helps the planet by making less waste and longer-lasting products.

TFL’s deep groove ball bearings work even in tough times. If a motor has a problem, these bearings keep going. Brands can count on TFL for important jobs. Good making and careful checks make TFL a top pick for brands everywhere.

Customization and Support

Every brand has unique requirements, and TFL is dedicated to meeting them. We specialize in creating custom deep groove ball bearings tailored for various motor applications. TFL collaborates closely with brands to design bearings that perfectly align with their specific needs, ultimately enhancing product performance.

Beyond customization, TFL is committed to providing exceptional after-sales support and service. International clients receive comprehensive assistance from the initial consultation through to final implementation. Our support services include:

- Hosting and Site Design: We host the client’s website, ensuring it reflects their brand identity and aesthetic.

- Checkout/Cart Hosting: We provide a robust system for seamless customer ordering.

- Merchant Services: Our services cover payment processing, fraud prevention, and loyalty program management.

- API Documentation & Sandbox: Clients are provided with clear API guides and a secure testing environment.

- Technical Assistance: We offer support for technical issues and API usage.

- Order Tracking: We enable tracking of orders for delivery and support purposes.

- Customer Service Availability: Our customer service team is available year-round via phone and email.

- Order Summary & Invoices: We provide detailed order summaries and invoices for all transactions.

- Domain Setup Instructions: We offer clear instructions and assistance for domain configuration.

- Integration Support: We help with API setup and work with clients to ensure successful integration.

Brands can expect prompt responses and intelligent solutions from TFL. Our dedicated team assists with setup, troubleshooting, and ongoing maintenance. We rigorously check the quality of every custom order, ensuring that even specialized bearings meet the highest standards.

TFL’s unwavering focus on support, environmental responsibility, and operational excellence positions us as a trusted partner for brands sourcing deep groove ball bearings from China. Clients benefit from high-quality products, strong support, and environmentally conscious options for every motor.net, and working better makes them a trusted partner for brands buying deep groove ball bearings from China. Brands get good products, strong help, and green choices for every motor.

Deep Groove Ball Bearings for Sourcing

Sourcing Deep Groove Ball Bearings from TFL

Big brands trust TFL when they buy deep groove ball bearings from China. TFL has many kinds of deep groove ball bearings for electric motors and cars. Their factories in China use new machines to make sure each bearing is made right. Brands can pick the best deep groove ball bearings for their motors. TFL’s team helps buyers pick what works best for electric vehicles and other machines.

TFL does not have set wait times or order limits for deep groove ball bearings. The sales team talks with each customer and gives details about buying deep groove ball bearings. This way, brands can plan their work and keep making products. Buyers can ask for samples and get quick answers. Buying deep groove ball bearings from TFL gives brands more control and trust.

Application in Electric Vehicles

Electric vehicles need deep groove ball bearings that last long and stay quiet. TFL’s bearings help electric motors in cars work well and save energy. These bearings make less noise and help electric vehicles work better. China deep groove ball bearings from TFL help electric vehicles grow fast all over the world.

Making electric vehicles needs strong and tough bearings. TFL’s deep groove ball bearings help motors run well in any weather. The car industry uses these bearings in motors, alternators, and other important parts. Brands choose TFL for deep groove ball bearings because they want their electric vehicles to work well and last long.

Performance in Critical Components

Deep groove ball bearings from TFL help many important parts work better. Electric motors in cars need these bearings to run smooth. Pumps, compressors, and food machines use TFL’s bearings for better work and less stopping. Boats and outdoor machines need bearings that do not rust and work in any weather.

- Electric motors and alternators in cars

- Pumps and compressors in big machines

- Food machines for clean and safe work

- Home appliances for quiet and strong use

- Boats and outdoor machines for no rust

TFL’s deep groove ball bearings stop electric damage and keep motors safe. The C4 clearance design helps motors work well and smooth. Brands save money because they fix things less and have fewer stops. These bearings help electric vehicles and other machines work their best every day.

Brands that pick TFL’s deep groove ball bearings from China get better work, longer motor life, and stronger parts in every machine.

Why Global Brands Choose TFL

Proven Reliability and Certifications

TFL is a trusted partner for many big brands. These brands want deep groove ball bearings that always work well. TFL makes sure their products are good by following strict rules. The company uses advanced tools and checks each step. This focus on quality helps brands trust every product.

TFL’s deep groove ball bearings have important certifications. These include:

- Designed by the European International Standard ISO 492

- Applied for ISO9001:2000 certification for their brand

These certifications show TFL’s products meet world standards. Brands in cars and electric vehicles need these rules for safety and good work. TFL’s promise to make quality products helps brands avoid problems and build trust with buyers.

TFL also gives strong help after you buy. The team answers technical questions and helps track orders. They also support custom solutions. Brands know they can get help from TFL before and after buying. This service makes TFL a top pick for companies everywhere.

Case Example: Electric Vehicle Manufacturer

A famous electric vehicle brand needed deep groove ball bearings for high speeds and quiet use. The company picked TFL because of their skill and good service. TFL worked with the brand to design bearings for electric vehicles.

The motor ran smoother and lasted longer. The deep groove ball bearings made less noise and saved energy. The brand had fewer breakdowns and less time stopped. TFL’s team gave fast help after the sale and fixed problems quickly.

This teamwork helped the electric vehicle brand get a better name. Customers liked the quiet ride and strong motors. The brand now uses TFL’s deep groove ball bearings in all new cars. TFL’s way of making and helping made a big difference in the car market.

“TFL’s deep groove ball bearings helped us give a better ride. Their support and quality checks made us feel safe.”

— Engineering Manager, Leading Electric Vehicle Manufacturer

Case Example: Industrial Equipment Brand

A big industrial equipment company had trouble with bearing failures. They needed deep groove ball bearings for heavy loads and hard jobs. TFL gave them a solution with strong making and careful checks.

TFL’s team helped pick the right deep groove ball bearings for each machine. The bearings worked well in pumps, compressors, and other important parts. The company saw machines last longer and cost less to fix. TFL’s help after the sale made it easy to track orders and solve problems fast.

Now, the equipment brand trusts TFL for all deep groove ball bearings. The company likes TFL’s world certifications and strong making. TFL’s team keeps helping with training and advice.

| Benefit | Result for Manufacturer |

|---|---|

| Longer equipment life | Fewer breakdowns and repairs |

| Reliable after-sales | Fast help with orders and questions |

| International standards | Confidence in quality and safety |

TFL’s deep groove ball bearings help many companies in cars and other fields. The company’s focus on quality, service, and world rules makes it the top choice for global brands. TFL’s skill and help after the sale help brands do well in electric vehicles, machines, and more.

TFL is the best pick for brands that need deep groove ball bearings. Their deep groove ball bearings are very quiet and last a long time. They help save money and work well for many uses. TFL cares about the planet, so their deep groove ball bearings help with green goals. People who buy parts like TFL’s deep groove ball bearings for cars and machines. TFL’s deep groove ball bearings give:

- More than 10 years making and selling deep groove ball bearings

- Custom deep groove ball bearings, OEM help, and quick answers

- Expert help, good prices, and deep groove ball bearings that save money

- Deep groove ball bearings that are quiet, exact, and keep out dirt

- ISO9001:2000 certified deep groove ball bearings and strong tests

- Deep groove ball bearings with a 30-day return and good feedback

- Deep groove ball bearings in many sizes for all kinds of jobs

- Deep groove ball bearings that help brands be more eco-friendly

- Deep groove ball bearings with new ideas, help anytime, and easy changes

- Deep groove ball bearings with good deals for big orders

Pick TFL for deep groove ball bearings that work better, help the planet, and give great value. Reach out to TFL now to get a price or find out more.

FAQ

What makes TFL’s motor bearings ultra-quiet?

TFL uses new technology and strong materials. Their deep groove ball bearings help lower noise and shaking. Motors run smooth and quiet with these bearings. People can tell the products are better.

Can TFL customize deep groove ball bearings for special needs?

Yes! TFL helps brands make custom bearings. They fit each motor’s size and how it works. This makes products different from others in stores.

Tip: Custom bearings from TFL help brands beat other companies.

How does TFL ensure fast delivery for global brands?

TFL owns its own factories in China. They control every step of making bearings. Brands get their orders fast and do not have to wait long.

Are TFL’s bearings certified for international standards?

Yes, they are. TFL’s deep groove ball bearings meet ISO9001:2000 and ISO 492 rules. Brands trust these rules for safety and good quality.

Why should brands choose TFL over other suppliers?

TFL gives quiet and strong bearings at good prices. Their team helps brands from start to finish. Brands save money, make better products, and earn trust from buyers.

Pick TFL for bearings you can count on and great help. Ask TFL for a price today!