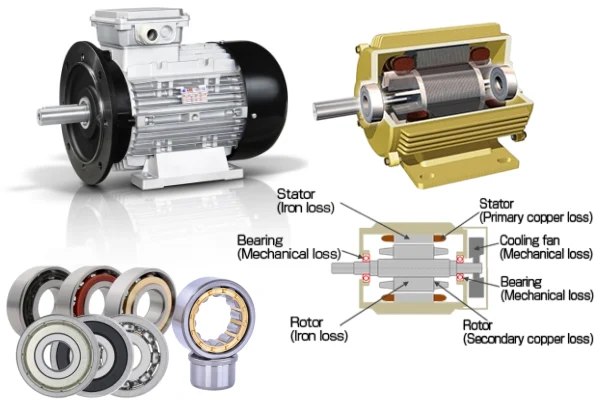

In the dynamic and ever-evolving landscape of modern industry, motors serve as the fundamental driving force behind countless applications, from intricate robotic systems to large-scale industrial machinery and the burgeoning electric vehicle market. The efficiency, reliability, and longevity of these motors are inextricably linked to the quality and suitability of their internal components, especially the bearings.

TFL is a reliable factory-direct bearing supplier, renowned for producing high-quality bearings for a wide range of motors. From industrial machines to electric vehicles, TFL Bearings are engineered to enhance motor performance, reliability, and efficiency. With decades of experience and advanced manufacturing capabilities, TFL has become a trusted choice for motor designers seeking precision and durability.

Motor-Bearing Selection Reference Table

| Motor Type | Recommended TFL Bearing Type | Key Characteristics (Brief) |

| Industrial / High-Efficiency | Deep Groove Ball (6200), Cylindrical Roller (NU/NJ), Angular Contact (7000) | Low friction, high radial load |

| Variable Frequency Drive (VFD) | Insulated (ERB), Angular Contact (7200), Cylindrical Roller (NU/NJ) | Insulated, high speed, resistant to electrical erosion |

| Precision Control | Angular Contact (7000/7200), Ceramic Hybrid (CERAMIC) | High rigidity, precision, low friction |

| Pump/Fan/Compressor | Self-aligning Ball (1200/1300), Cylindrical Roller (NU/NJ), Double Row Angular Contact (3200) | Adapts to misalignment, high radial load, combined load |

| Electric Vehicle (EV) | High-Speed Angular Contact (7000/7200), Ceramic Hybrid (CERAMIC) | Extremely high speed, anti-electrolysis, combined load |

| Consumer/Tool | Deep Groove Ball (6200/6300), Sealed Deep Groove Ball (6202-2RS) | Versatile, high speed, dust and waterproof |

| Heavy-Duty/Special | Cylindrical Roller (NN/NJ), Double Row Ball (1200/1300), Sealed Bearings (ERB) | Extreme loads, shock resistance, safety, vibration |

Industrial and High-Efficiency Motors

High-Efficiency Industrial Motors – Recommended Bearings

High-efficiency industrial motors are widely used in manufacturing, conveyors, pumps, and HVAC systems. These motors often operate continuously under medium to high radial loads, sometimes with moderate axial loads. Improper bearing selection may lead to premature wear, excessive vibration, or reduced energy efficiency.

For these motors, TFL recommends:

- Deep Groove Ball Bearings (6200 Series, e.g., 6202, 6204): Ideal for general-purpose industrial motors, providing low friction and smooth rotation at medium and low speeds.

- Cylindrical Roller Bearings (NU/N/NN Series): Suitable for motors with high radial loads, providing excellent load-carrying capacity and long service life.

- Angular Contact Ball Bearings (7000/7200 Series): Support moderate axial loads and are suitable for high-speed industrial applications.

Tip: When choosing bearings, consider load direction, operating speed, and lubrication type. Proper lubrication and correct mounting significantly extend bearing life.

Variable Frequency Drive (VFD) Motors

Increasingly prevalent in modern automation, VFD motors are utilized in applications such as precise pump control, advanced fan systems, and sophisticated air conditioning units. These motors are characterized by their ability to operate at varying speeds, which can introduce high-frequency electrical currents that, if not properly managed, can lead to electrical erosion (fluting) of the bearing races. They also experience fluctuating and dynamic loads. TFL addresses these challenges with specialized solutions.

Recommended Bearings:

- Insulated Bearings (ERB series): Specifically designed with an electrically insulating coating to prevent current passage and eliminate the risk of electrical erosion, significantly extending bearing life.

- Angular Contact Ball Bearings (7200/7300 series): Ideal for high-speed applications requiring robust axial and radial load support.

- Cylindrical Roller Bearings (NU/NJ series): Excellent for handling the heavy radial loads often associated with these dynamic VFD motor operations .

Servo Motors

Servo motors are the brains and brawn of precision automation, essential for industrial robotics, CNC machinery, and high-precision positioning systems. Their defining characteristics include extremely high precision, rapid acceleration and deceleration capabilities, and immediate response to control signals. The bearings in servo motors must accommodate high speeds and maintain exceptional positional accuracy with minimal runout.

Recommended Bearings:

- Angular Contact Ball Bearings (7000/7200 series): Offer high stiffness, excellent axial and radial load capacity, and precise shaft guidance critical for accurate motion.

- Ceramic Hybrid Bearings (CERAMIC series): Provide superior performance, reduced wear, and extended operating life for applications demanding even greater rigidity, lower friction, and higher speeds.

Stepper Motors

Stepper motors are fundamental components in applications requiring precise, incremental motion, such as 3D printers, optical equipment, and various forms of miniature positioning devices. They are known for their ability to hold a position without continuous feedback and are typically characterized by their compact design and relatively low torque output. The bearings in these motors need to be small, efficient, and provide smooth rotation to ensure accurate stepping.

Recommended Bearings:

- Miniature Ball Bearings (MR series): Ideally suited for the compact nature of stepper motors, offering low friction and smooth operation in confined spaces.

- Miniature Angular Contact Bearings: Can enhance precision and slightly increase load capacity in a compact form factor for specific designs .

Linear Motors

Linear motors are revolutionizing automation by providing direct linear motion without the need for rotary-to-linear conversion mechanisms. They are employed in high-speed pick-and-place machines, precision cutting systems, and advanced material handling. The key operational characteristic is the demand for extremely smooth, low-friction movement to ensure high accuracy and dynamic response along a linear path. While the “motor” itself doesn’t use traditional rotary bearings, the associated guidance systems for the moving parts are critical.

Recommended Bearings:

- Special Guide Bearings: Specifically designed to support the moving carriages of linear motor systems, ensuring ultra-smooth, low-friction linear translation, minimizing vibrations and maximizing precision.

High-Speed Spindle Motors

Found at the heart of advanced machine tools, CNC machining centers, and high-speed grinding equipment, these motors are designed for applications requiring extremely high rotational speeds, often exceeding tens of thousands of RPMs. The demand for exceptional precision and rigidity is paramount to achieve fine finishes and accurate cuts. The bearings must be capable of operating reliably under these extreme centrifugal forces and thermal conditions.

Recommended Bearings:

- Angular Contact Ball Bearings (7000 series): Meticulously designed with optimized contact angles and precision manufacturing to provide the necessary high stiffness, low runout, and excellent high-speed performance required for such demanding operations.

Robot Joint Motors

The sophisticated movements of industrial robots rely on a series of precisely controlled joint motors. These motors often operate in continuous motion cycles, experiencing complex and varying load conditions as the robot arm articulates and manipulates objects. The bearings must be compact, capable of handling combined loads, and ensure high positional accuracy and smooth, repeatable motion.

Recommended Bearings:

- Angular Contact Ball Bearings: Offer high stiffness and ability to handle combined loads in a compact form factor.

- Miniature Ball Bearings: Suitable for scenarios where space is extremely limited but precision and smooth motion are still critical.

Motors for Pumps, Fans, and Compressors

Pump Motors

Pump motors are omnipresent in industries ranging from agriculture and municipal water systems to chemical processing and oil & gas. They often handle varying liquid pressures and volumes, leading to fluctuating loads and sometimes misalignment. The bearings must compensate for potential shaft deflections and reliably carry radial and axial forces.

Recommended Bearings:

- Self-aligning Ball Bearings (1200/1300 series): Excellent for pump motors as they can accommodate angular misalignment, preventing premature wear caused by shaft deflection.

- Cylindrical Roller Bearings (NU/NJ series): Provide superior load-carrying capacity and rigidity for applications with higher radial loads and robust requirements.

Fan Motors

Fan motors are integral to ventilation systems in commercial buildings, industrial cooling, and exhaust systems. They typically operate at moderate to high speeds, with loads primarily radial due to the fan impeller. Smooth, quiet operation is often desired, along with long service life in potentially dusty or humid environments.

Recommended Bearings:

- Deep Groove Ball Bearings (6200/6300 series): Popular choice due to their balanced performance, good speed capability, and ability to handle both radial and light axial loads.

- Angular Contact Ball Bearings (7200/7300 series): Offer enhanced rigidity and performance for more demanding applications where higher speeds or combined loads are present.

HVAC Compressor Motors

The heart of any air conditioning or refrigeration system, HVAC compressor motors work under high, often fluctuating, loads and temperatures. They demand bearings that can withstand significant axial thrust and radial forces, ensuring the efficient compression of refrigerants. Reliability is key to avoiding costly system downtime.

Recommended Bearings:

- Double Row Angular Contact Ball Bearings (3200 series): Specifically designed to excel in compressor motors, offering high stiffness and the ability to accommodate substantial combined radial and axial loads common in compressor operations.

EV and Mobility Motors

EV Traction Motors

These are the primary propulsion units for electric vehicles, operating under extremely high speeds, significant torque demands, and often experiencing considerable thermal variations. The bearings must be robust, precise, and, crucially, resistant to the electrical currents that can flow through them, leading to damage.

Recommended Bearings:

- High-Speed Angular Contact Bearings (7000/7200 series): Engineered for the extreme rotational speeds and combined loads found in EV traction motors, offering superior rigidity and precision.

- Ceramic Hybrid Bearings (CERAMIC series): With their electrically insulating properties and higher speed capabilities, they are increasingly vital in mitigating electrical erosion and extending the life of EV traction motor bearings.

E-Bike Motor

E-bike motors, whether hub-mounted or mid-drive, require compact, lightweight, and efficient bearings to contribute to the overall performance and range of the bicycle. They typically operate at moderate speeds with varying loads depending on terrain and rider input.

Recommended Bearings:

- Deep Groove Ball Bearings (6202/6204): Commonly used for their balanced performance in a compact form factor.

- Miniature Angular Contact Bearings: Beneficial in designs where enhanced axial stiffness or slightly higher precision is required for smooth power delivery.

E-Scooter Hub Motors

Electric scooter hub motors are integrated directly into the wheel, demanding extremely compact and robust bearings that can withstand road vibrations, dirt, and varying loads, all within a very limited space. Durability and smooth, quiet operation are essential for rider experience and product longevity.

Recommended Bearings:

- Miniature Ball Bearings (MR series): Perfectly suited for these highly constrained applications, offering reliable performance, low friction, and the necessary compact dimensions.

Rail Transit Traction Motors

These are heavy-duty motors powering trains, trams, and subways, operating under immense loads, high speeds, and often harsh environmental conditions. The bearings must offer exceptional reliability, shock resistance, and long service life to ensure the safety and efficiency of public transportation systems.

Recommended Bearings:

- Cylindrical Roller Bearings (NU/NJ/NN series): Preferred choice for their high radial load capacity, rigidity, and reliable performance under challenging conditions.

Elevator Traction Motors

Elevator traction motors are critical for vertical transportation, requiring quiet, smooth, and highly reliable operation to ensure passenger comfort and safety. These motors typically handle significant and continuous loads, with bearings needing to provide consistent performance over millions of operational cycles.

Recommended Bearings:

- Cylindrical Roller Bearings (NU/NJ series): Highly suitable due to their high radial load capacity and excellent durability, essential for the continuous and heavy-duty operation required in elevator systems.

Consumer and Tool Motors

Power Tool Motors

Power tools such as drills, saws, and grinders operate at high speeds and experience significant dynamic loads and vibrations. The bearings must be robust enough to withstand these conditions while maintaining smooth operation and contributing to the tool’s overall durability and user comfort.

Recommended Bearings:

- Deep Groove Ball Bearings (6200/6300 series): Widely used for their versatility, good speed capability, and ability to handle combined loads in demanding power tool environments.

Garden Tool Motors

Garden tools like lawnmowers, trimmers, and leaf blowers operate in outdoor environments, often exposed to dirt, moisture, and varying temperatures. The bearings in these motors need to be well-protected from contaminants and capable of reliable performance under challenging conditions.

Recommended Bearings:

- Sealed Deep Groove Ball Bearings (6202-2RS): Equipped with two rubber seals, providing excellent protection against dust, water, and debris, ensuring extended bearing life and reliable operation in outdoor settings.

Washing Machines Motors

Washing machine motors are subject to significant and often unbalanced loads during spin cycles, as well as exposure to moisture and detergents. The bearings must be durable, resistant to these elements, and capable of providing quiet, stable operation throughout the machine’s life cycle.

Recommended Bearings:

- Deep Groove Ball Bearings (6203/6204, 6300 series): Chosen for their robust construction, efficient handling of radial and axial loads, and proven reliability in humid and variable-load environments, contributing to longevity and quiet performance.

Specialized and Heavy-Duty Motors

Certain industrial applications demand motors that operate under extreme or hazardous conditions, requiring bearings with highly specialized designs and materials. TFL excels in providing these niche solutions, ensuring safety, compliance, and unmatched performance in the most challenging environments.

Explosion-Proof Motors

Explosion-proof motors are designed to operate safely in hazardous atmospheres where flammable gases, vapors, dust, or fibers are present. The bearings in these motors must comply with stringent safety standards, often requiring sealed designs to prevent any sparks or hot surfaces from igniting the surrounding environment.

Recommended Bearings:

- Sealed Bearings (ERB/6200-2RS): The sealed design ensures lubricants and internal components are contained, preventing contamination and eliminating potential ignition sources.

- Insulated Bearings (ERB series): Can be adapted to prevent current passage, further enhancing safety in explosive atmospheres.

Vibrating Motors

Vibrating motors are purpose-built to generate vibration for applications such as industrial feeders, screens, and compactors. The bearings in these motors are subjected to continuous, high-frequency, and often severe dynamic loads. They must be exceptionally robust and resistant to fatigue to ensure reliable operation and long service life under constant vibratory stress.

Recommended Bearings:

- Double Row Ball Bearings (1200/1300 series): Their dual-row design provides enhanced radial and axial load capacity, as well as superior rigidity and resilience against constant impact and fatigue common in vibratory applications.

Crane & Metallurgical Motors

Motors used in cranes, hoists, and metallurgical equipment operate under extreme conditions, including very heavy loads, shock loads, high temperatures (especially in metallurgy), and dusty environments. The bearings must be engineered for maximum strength, durability, and resistance to harsh industrial elements to prevent catastrophic failures and ensure safety.

Recommended Bearings:

- Cylindrical Roller Bearings (NN/NJ series): Top choice for their ability to handle exceptionally high radial loads, superior rigidity, and excellent durability against shock and continuous heavy operation, indispensable for safety-critical heavy industrial applications.

Conclusion

TFL stands as a premier expert in the field of bearing solutions, offering an extensive and versatile range designed to meet the precise demands of virtually every motor type. Our commitment is to provide the absolutely ideal bearing for any application, regardless of its operational challenges or specific requirements.

From the intricate and sensitive servo motors commonly found in advanced robotics, which demand exceptional precision and smooth operation, to the robust and heavy-duty crane motors responsible for lifting tons of material, TFL consistently delivers. Each bearing is precisely engineered to not only guarantee optimal performance but also to significantly extend the operational longevity and reliability of the entire motor system.

As a proud and leading Chinese bearing manufacturer, TFL distinguishes itself through a steadfast dedication to excellence. We uphold rigorously applied quality control standards at every stage of production, integrate state-of-the-art innovative engineering practices, and maintain an unparalleled customer-centric approach. This philosophy ensures that our clients’ specific needs are always at the very core of our business operations.

We are deeply committed to forging lasting partnerships with our clients. These relationships are built on a foundation of unwavering trust, proven reliability, and the superior, consistent performance of our high-quality products. With TFL, you choose a partner dedicated to your success and the enduring efficiency of your motor systems.