Slewing ring bearings are very important in tunnel boring machines. These big machines use slewing ring bearings to turn heavy parts. They also help keep the machine steady when building tunnels. Engineers trust these bearings to handle strong forces. They also help the equipment move without problems. In tunnel boring machines and dredgers, slewing ring bearings hold up heavy loads. They also make the machines safer. Good bearings help every project keep going without stopping.

Key Takeaways

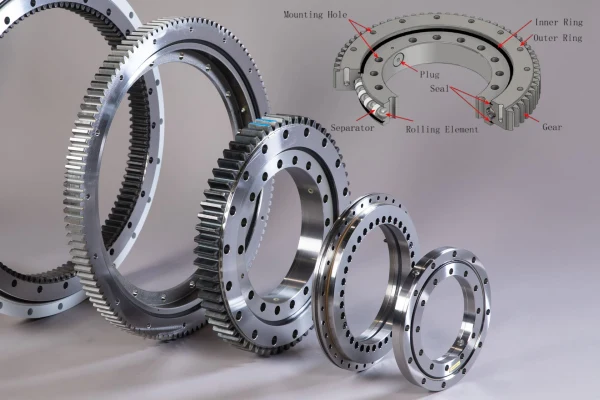

Slewing ring bearings let tunnel boring machines and dredgers turn heavy parts easily. They also help hold strong forces safely. These bearings have special designs with rolling parts, seals, and gears. These parts keep machines steady and safe from dirt and damage. Big bearings can handle many forces like pushing, pulling, and twisting. This helps machines last longer and work better. Regular care is important for bearings. Adding grease, checking seals, and fixing bolts keeps them working well. This also stops expensive breakdowns. Using strong materials and smart designs helps bearings fight rust and wear. This is important in hard places like tunnels and underwater.

Key Features

Slewing ring bearings are special because of their design. Each one has an inner ring and an outer ring. There are rolling parts like balls or rollers inside. A cage holds these rolling parts in place. Seals help keep dirt out and oil in. All these parts work together so the bearing can turn smoothly. The bearing is very wide, so it can hold big machines. Some types let wires or pipes go through the middle. This keeps important parts safe and saves space.

A table below shows some main features:

| Feature | Description |

|---|---|

| Load Capacity | Handles large axial, radial, and moment loads at the same time |

| Mounting Holes | Makes it easy to attach the bearing to machines |

| Gears | Internal or external gears help transmit torque |

| Lubrication | Oil holes allow for easy maintenance |

| Seals | Keep out dirt and hold in lubrication |

| Types | Four-point contact ball, cross roller, three-row roller, and more |

| Size | Large diameter, sometimes over 10,000 mm, fits heavy-duty needs |

Modern slewing ring bearings use strong steel. They also get special heat treatments to make them tougher. Some have coatings that stop rust. This is good for machines that work in wet places. New designs use sensors to watch the bearing all the time. These sensors help workers find problems early.

Load Handling

Slewing ring bearings must hold up many kinds of forces. These include forces that push down or pull up. They also handle forces from the side. Some forces try to tilt or turn the bearing. Tunnel boring machines and dredgers use the bearing while facing all these forces. The bearing also has to handle high torque, which makes things spin. A three-row roller bearing can take a lot of torque. It spreads out the different forces in each row. This makes the machine safer and helps it last longer.

Big tunnel boring machines use bearings that are 2.5 to 6 meters wide. Some special ones are even bigger than 10,000 mm. These bearings can handle very strong forces and torque. They are needed to build tunnels and dredge safely and well.

Role in Tunnel Boring Machines

Cutter Head Support

Tunnel boring machines have a big cutter head. It breaks rock and soil to make tunnels. The cutter head needs to spin easily and hold heavy weight. Slewing ring bearings join the cutter head to the main part of the machine. These bearings help the cutter head turn with hydraulic motors. The motors push on the bearing to make the cutter head spin and dig.

Slewing ring bearings are also called main bearings in tunnel boring machines. They keep the cutter head steady. They move forces from the cutter head to the rest of the machine. These forces are:

- Axial loads push or pull along the tunnel.

- Radial loads come from the sides.

- Moment loads try to twist or tilt the cutter head.

The three-row cylindrical roller bearing design is good for these jobs. It spreads the forces over different rows. This design lowers stress on the machine and helps the cutter head turn with less rubbing. The rolling parts inside the bearing move in tracks. This lets the cutter head turn in a safe way. Spacers keep the rollers apart. Seals stop dirt from getting in and keep oil inside. These things help the bearing last longer and work better.

Tunnel boring machines need very big bearings. Some bearings are several meters wide. Their size helps them hold the weight and forces from the cutter head and motors. The bearings are made from 50Mn, 42CrMo, and C45 steel. These metals make the bearing strong and tough. The bearing must also fight damage from dust, water, and shaking while digging tunnels.

Note: Taking care of the bearing, like adding oil and checking seals, stops it from breaking early. Good care keeps the cutter head moving and helps avoid delays when building tunnels.

Shield Rotation

The shield is the main part of tunnel boring machines. It keeps workers and tools safe while digging tunnels. The shield needs to turn and move forward as the machine works. Slewing ring bearings help with this job. They hold up the turning part at the top of the shield and help it spin with hydraulic motors.

A three-row roller bearing design gives the shield strong support. It can hold big axial, radial, and moment loads. This matters because the shield faces strong forces from the ground and cutter head. The bearing can also adjust itself a little. This means it can fix small mistakes or bends in the machine. This helps the shield stay steady and safe.

The table below shows how each bearing part helps the shield turn and stay stable:

| Bearing Component | Role in TBM Shield Rotation and Stability |

|---|---|

| Three-row roller design | Holds big loads, adjusts itself, fixes small mistakes, keeps shield steady |

| Thrust rollers | Hold up and balance vertical and tilting forces |

| Radial rollers | Take side forces and gravity, help with turning |

| Auxiliary thrust rollers | Help balance tilting forces, make the machine more stable |

| Main bearing system | Moves all forces, helps shield turn smoothly, keeps the machine steady |

| Bearing characteristics | Big size, slow turning, strong, lasts long, needs good making and care |

Tunnel boring machines use hydraulic motors to spin the shield. The motors push on the bearing so the shield turns slowly but with strong force. The bearing must work well in tough places. It should last as long as the machine, which is many years.

- Three-row roller slewing bearings can handle heavy and tricky forces when the shield turns.

- The design makes movement smooth and quiet, and lowers shaking.

- The small design saves space and makes putting it in easier.

- The bearing holds up the shield during every part of tunnel digging.

Tunnel boring machines need strong bearings to keep working. Good materials, smart design, and regular checks help the bearing last longer. This keeps tunnel digging safe and helps finish the job well.

Role in Dredgers

Rotational Support

Dredgers have big cutter heads and arms. These parts dig and move soil underwater. They are heavy and must turn easily. Slewing ring bearings help them do this job. Each bearing is strong and very exact. It holds up the cutter head or arm. The bearing has gears inside. These gears link to hydraulic motors. When the motors start, they spin a gearbox. The gearbox turns the teeth inside the bearing. This lets the cutter head or arm spin all the way around.

The bearing deals with many forces. It holds weight from above. It also handles pressure from the sides and twisting. Hydraulic motors help the cutter head or arm move just right. The bearing passes torque from the motors to the moving part. This helps the dredger work well in hard places. It does not lose control.

Tip: Slewing ring bearings with hydraulic motors make dredgers work faster. Smooth turning helps operators dig and lift with ease.

A table below shows how each part helps:

| Component | Function in Dredger Operation |

|---|---|

| Slewing ring bearing | Holds heavy loads and lets it spin all the way |

| Internal gears | Move torque from hydraulic motors |

| Hydraulic motors | Give power for smooth, steady movement |

| Gearbox | Links motors to bearing, controls speed and force |

Marine Environment Challenges

Dredgers work in tough places. Saltwater, sand, and mud can hurt machine parts. The bearing faces many dangers. Rust is a big problem. Saltwater and wetness can damage metal. Makers use strong steel like 50mn and 42CrMo. They add special coatings and oil to fight rust and heat.

Scratches are another problem. Sand and dirt can wear down the bearing. Good seals protect the inside. Seals keep out water, dust, and dirt. There are rubber, brush, and metal seals. If a seal breaks, water and sand get in. This causes more damage and can break the bearing.

Hydraulic motors need care too. If the bearing is dirty or dry, friction goes up. This makes the motors work harder and wear out faster. Regular checks and care stop these problems.

Dredger workers follow a strict care plan:

- Check bolts before using and after 100 hours.

- Check bolts again at 300 hours.

- Keep checking every 500 hours.

- Oil the bearing every 200 to 500 hours, based on work.

- Oil more often in wet or dirty places.

- Watch for wear, damage, or leaks.

- Clean and change bad parts fast to stop bigger issues.

Note: Good care keeps the bearing and motors working well. This helps the dredger last longer and saves money on repairs.

A dredger faces many hard forces. Bad alignment and too much weight can cause uneven wear. Workers must control loads and look for trouble. Using the right steel, coatings, and seals helps the bearing last in tough places.

Bearing Maintenance and Reliability

Common Issues

Slewing ring bearings in tunnel boring machines and dredgers have many problems. Heavy loads and spinning all the time wear down the bearing surfaces. Dirt, water, and sand can get inside, especially in wet places. This can make the bearing rusty and break early. Not enough grease is a big problem too. If there is not enough grease, the bearing gets hot and wears out faster. Too much grease can also make it overheat and leak.

If the bearing is not put together right, it can be crooked. When it does not fit well, it shakes or makes noise. Workers might see too much space or gaps in the bearing. These problems can make the bearing break sooner and stop work in tunnels or dredgers.

A table below shows common problems and what they do:

| Issue | Effect on Bearing Life |

|---|---|

| Poor lubrication | Makes it wear out and get hot |

| Contamination | Causes rust and damage |

| Misalignment | Makes it shake and noisy |

| Excessive clearance | Makes it unstable |

| Overloading | Makes it break early |

Best Practices

Operators can do some things to help slewing ring bearings last longer. They should use good semi-synthetic grease often. This grease protects the bearing from wearing out, rust, and shaking. It sticks well and works in hot and wet places. Good grease helps machines keep working and not stop.

Workers need to set the bearing clearance when putting it together. This stops damage from gaps or uneven weight. After putting it in, they should check for problems early. Looking for shaking, noise, and heat helps make sure it fits right. Using the right tools to check radial clearance helps the bearing move smoothly.

The bearing should fit close to the shaft shoulder to stay straight. Operators should also look at the seals and fasteners. These steps help keep machines safe and working well.

Tip: Doing regular checks and putting the bearing together carefully helps it last longer, even in hard jobs like digging tunnels and dredging.

Here is a list of good steps:

- Use good grease and put it on right.

- Set the bearing clearance when building.

- Check the bearing after putting it in.

- Look for bumps, grease flow, and seals.

- Use the right tools to check radial clearance.

- Make sure it fits close to the shaft shoulder.

Slewing ring bearings help hold up heavy parts. They also let tunnel boring machines and dredgers turn smoothly. Good bearings make the machines work better and break down less. This means workers do not have to fix them as often. The machines can keep working for a long time without stopping. This saves money and helps finish tunnel projects on time.

Operators who pick strong bearings have fewer problems and better results. TFL Bearings gives expert help for tough jobs.

FAQ

What is a slewing ring bearing?

A slewing ring bearing is a big bearing. It holds up heavy things and lets them turn. Engineers put it in machines like tunnel boring machines and dredgers. It helps these machines move safely and without trouble.

Why do tunnel boring machines need slewing ring bearings?

Tunnel boring machines need slewing ring bearings to hold the cutter head and shield. These bearings take strong forces when digging tunnels. They help the machine dig and move ahead without getting stuck.

How do slewing ring bearings handle harsh environments?

Makers use tough steel and special coatings to protect slewing ring bearings. Seals stop dirt, water, and sand from getting inside. Checking and caring for the bearing helps it last longer in hard places like tunnels or underwater.

What maintenance do slewing ring bearings require?

Operators check bolts, add grease, and look at seals often. They watch for signs of damage or wear. Good care keeps the bearing working well and stops problems during tunnel digging or dredging.