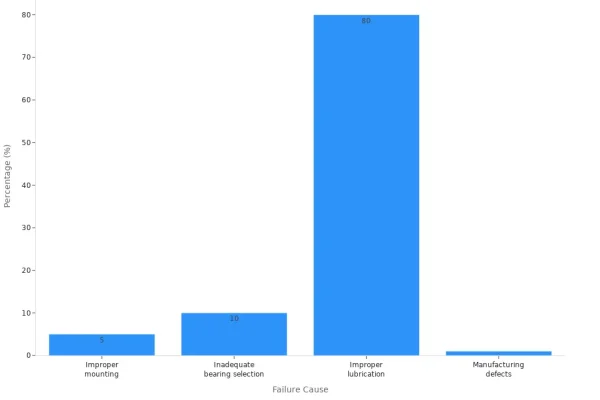

Learning the right words for roller bearing parts is important. It helps you avoid expensive mistakes. Improper mounting and bad bearing choices cause about 15% of early bearing failures. You can see this in the chart below:

When you know rolling bearings terminology, you make better choices. This helps with equipment and maintenance. This guide will help you learn at every step. If you need more help, TFL Bearings is here for you.

Key Takeaways

- Roller bearings help machines move easily. They do this by lowering friction. They also hold up heavy things. Knowing the main parts is important. These parts are the inner ring, outer ring, rollers, and cage. This helps you see how bearings work. Different roller shapes do different jobs. Picking the right type helps machines work better and last longer. Using the right words and codes helps a lot. It makes picking, putting in, and caring for bearings easier. Careful assembly is important. Good lubrication is needed too. The shaft and housing must fit well. This helps bearings last longer and stops them from breaking.

Roller Bearing Basics

A roller bearing is a machine part that helps things move smoothly. You find it in many machines, from cars to factory equipment. It uses rolling elements, called rollers, placed between two rings. These rollers help reduce friction and support heavy loads. Roller bearings can handle both radial and axial forces. The size, width of the bearing, height of the bearing, and outer diameter all affect how much load it can carry and how fast it can spin. You need to use the right lubrication and position the bearing correctly to make it last longer. This matches the standard engineering definition for roller bearings.

Main Components

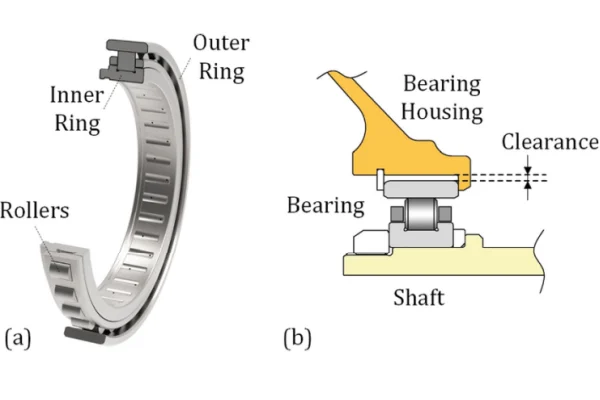

Every roller bearing has four main parts. Each part has a special job. You can see their functions in the table below:

| Component | Function |

|---|---|

| Inner Ring | Fits onto the rotating shaft. It gives a surface for the rollers to move on. |

| Outer Ring | Holds the rollers and fits into the housing. It keeps the bearing together. |

| Rollers | Roll between the rings. They reduce friction and carry the load. |

| Cage | Keeps the rollers spaced out and guides them. It helps the rollers stay in line. |

You need all these parts to make the bearing work well. If one part fails, the whole bearing can stop working.

Types of Rollers

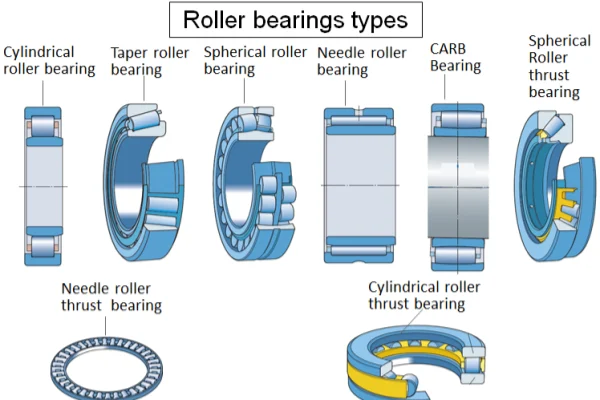

Roller bearings use different shapes of rollers. Each type works best for certain jobs. Here are the most common types:

| Roller Bearing Type | Roller Shape / Design | Load Handling Capability | Notes / Applications |

|---|---|---|---|

| Cylindrical Roller | Long, cylinder-shaped rollers | High radial and thrust loads | Used in high-speed, heavy-load machines |

| Tapered Roller | Rollers shaped like cones | Handles both radial and axial loads | Good for car wheels and gearboxes |

| Needle Roller | Thin, needle-like rollers | High radial loads, limited axial load | Fits in small spaces, used in cars and pumps |

| Thrust Roller | Rollers made for thrust (axial) loads | Mainly axial loads | Used where force pushes along the shaft, like in turntables |

A cylindrical roller bearing uses cylinder-shaped rollers. It can handle heavy loads and spins at high speeds. Needle roller bearings fit more rollers in a small space, so they work well when you have limited room. Tapered rollers can take both sideways and end-to-end forces. Thrust rollers are best when the main force pushes along the shaft.

How Roller Bearings Work

You can understand how a rolling bearing works by looking at what happens inside:

- The rollers move between the inner and outer rings. This rolling action reduces friction much more than sliding.

- The load from the shaft passes through the inner ring to the rollers. The rollers spread the load evenly to the outer ring.

- The cage keeps the rollers spaced out. This helps them roll smoothly and not bump into each other.

- The rolling motion creates less heat. This means the bearing can spin fast and last longer.

- Some bearings, like spherical roller bearings, can handle misalignment. They keep working even if the shaft and housing are not perfectly lined up.

- Sealed bearings keep grease inside and dirt out. This helps the bearing last longer.

Tip: Always check the width of the bearing and the outer diameter before choosing one. These sizes affect how much load the bearing can handle and how it fits in your machine.

You see roller bearings in many places because they make machines run smoother and last longer.

If you want to learn more or need help picking the right bearing, we at TFL Bearings are ready to help you every step of the way.

Rolling Bearings Terminology

Understanding basic terminology helps you communicate clearly and make better choices when working with rolling bearings. This section explains the most important terms, codes, and standards you will see in the world of roller bearing engineering.

Key Terms

You will see many technical words when you read about bearings. Here are some of the most common terms and what they mean:

| Term | Definition |

|---|---|

| Clearance | The small space inside a bearing that allows the rolling elements to move smoothly. Proper clearance helps the bearing run without too much friction or heat. |

| Preload | The force used to remove any play or looseness inside the bearing. Preload keeps the parts tight and helps with accuracy and less vibration. |

| Raceway | The smooth path on the inner and outer rings where the rollers or balls move. The raceway supports the load and guides the rolling elements. |

| Cage (Retainer) | The part that holds the rollers or balls in place and keeps them spaced out. The cage reduces friction and noise, making the bearing last longer. |

| Shield | A thin cover that protects the inside of the bearing from dust and dirt. Shields also help keep the lubricant inside. |

| Bearing Life (L) | The number of hours a bearing can work at a steady speed before it starts to wear out. |

| Bearing Rating Life (L10) | The time that 90% of a group of bearings will last without failing. This is a common way to measure bearing life. |

| Static Loads | The weight or force on a bearing when it is not moving. |

| Basic Load Rating (CB) | The amount of load a bearing can handle for one million turns without damage. |

| Lubrication | The process of adding oil or grease to reduce friction and wear inside the bearing. |

| Seal | A device that keeps oil or grease in and dirt out, helping the bearing last longer. |

| Safety Factor | A number that shows how much extra load a bearing can handle beyond normal use. |

Tip: If you see a term you do not know, check this table or ask an expert. Knowing the right words makes it easier to choose and use the correct roller bearing.

Common Codes and Symbols

Manufacturers use codes and symbols to describe the features of rolling bearings. These codes help you understand what type of bearing you have and what it can do. Here are some of the most common codes:

- K: Tapered bore. This means the hole in the bearing is not straight but slightly angled.

- L: Light series. This code shows the bearing is lighter and may fit in smaller spaces.

- R: Reinforced or special design. The bearing may have extra strength or a unique feature.

- S: Stainless steel. The bearing uses stainless steel for better rust protection.

- NS: Non-separable. You cannot take this bearing apart without damaging it.

You will also see codes for special types, like the four-point contact ball bearing. This type can handle both radial and axial loads in both directions. Codes and symbols make it easier to compare bearings from different manufacturers, but you should always check the details because not all codes are the same everywhere.

Manufacturers often follow international guidelines, but each company may add its own codes for special features. You may need to look up a code chart or ask for help when you see a new code.

ISO 5593 Standard

The ISO 5593 standard gives you a common language for rolling bearings. This standard lists the official words and their meanings for all types of rolling bearings, including accessories. ISO 5593 helps everyone use the same terms, so you can talk with engineers, suppliers, and customers without confusion.

ISO 5593 covers words for parts, types, and features of bearings. It does not include terms that belong to other standards or very special types. The American Bearing Manufacturers Association (ABMA) also uses ISO 5593 as part of its own rules. Many companies around the world follow this standard, but some may use extra terms for their own products.

Note: Using ISO 5593 makes it easier to read catalogs, order parts, and work with people from other countries. You can trust that the basic terminology will mean the same thing everywhere.

If you want to learn more about roller bearing terms or need help choosing the right product, we at TFL Bearings are always ready to support you.

Shaft, Housing, and Rolling Bearing System

Shaft

The shaft is the main rotating part in a roller bearing system. You mount the bearing’s inner ring on the shaft. This setup lets the shaft spin smoothly while carrying heavy loads. When you choose a shaft, you need to think about several important points:

- The shaft must give strong support to the bearing inner ring.

- A tight fit between the shaft and the bearing inner ring stops the ring from slipping or moving. This fit helps spread the load evenly and prevents damage like wear or corrosion.

- The shaft should handle both radial and axial loads, as well as the speed and temperature of your machine.

- The ends of the shaft must be flat and square to the axis. This keeps the load even across the bearing.

- For some bearings, the shaft must allow for small movements along its length.

You also need to pick the right material for the shaft. Here are some common choices:

| Material Type | Examples | Standards | Key Properties |

|---|---|---|---|

Through hardening steels | 100Cr6 | ISO 683-17 | Hard, good for raceways, can be surface hardened |

| Case hardening steels | 17MnCr5, 18CrNiMo7-6, 16MnCr5 | DIN EN ISO 683-17, EN 10084 | Tough surface, strong core |

| Induction surface hardening steels | C56E2, 43CrMo4, Cf53 | DIN EN ISO 683-17, DIN 17212 | Good for flame or induction hardening |

These materials give the shaft the hardness and strength needed for long-lasting bearing performance.

Housing

The housing holds the bearing’s outer ring and keeps everything in place. You need a strong and well-designed housing to protect the bearing and help it last longer. Here are some things you should know:

- Cast iron housings work well for heavy-duty jobs because they absorb vibration and last a long time.

- Composite housings resist rust and work in places with chemicals.

- The housing material affects how well it handles shock, heat, and dirt.

- Good housing design keeps the shaft lined up, which helps the bearing run smoothly.

- The shape and fit of the housing spread the load across the bearing. This helps prevent early failure.

- ISO standards set tight tolerances for housing sizes, usually within 10 microns. This accuracy keeps the bearing from slipping or getting damaged.

A well-made housing helps your bearing work better and last longer.

Bearing Assembly

When you put together a roller bearing system, you need to follow careful steps to get the best results:

- Keep the area and bearings clean to stop dirt from getting in.

- Do not wash new bearings; they come ready to use.

- Store bearings in their packaging until you need them.

- Handle bearings gently and use the right tools, like induction heaters.

- Check that the shaft and housing are smooth and the right size.

- Install seals to keep out dust and moisture.

- Mount the bearing with even pressure and never hit it with a hammer.

- Add the correct lubricant as the maker suggests.

- Make sure the bearing sits square in the housing.

- After assembly, listen for odd noises and check for problems.

Common mistakes include misalignment, using the wrong fit, poor lubrication, and overheating. You can avoid these by following the right steps and using proper tools.

Careful assembly and the right parts help your roller bearing system run smoothly and last longer.

If you want expert advice or need help choosing the right shaft, housing, or bearing assembly, we at TFL Bearings are always ready to support you.

Radial and Thrust Roller Bearing Terms

Radial Bearing Parts

Radial bearings have many important parts. Each part helps the bearing do its job. The outer ring holds the bearing in place. The inner ring connects to the shaft and spins with it. Rolling elements are shaped like cylinders, barrels, or cones. They spread the weight out and help the bearing hold heavy loads. The cage keeps the rollers apart so they do not touch. This makes the bearing turn smoothly. Ribs on the rings help guide the rollers. They also let the bearing handle a little force along the shaft. The size of these parts changes how much weight the bearing can hold. Bigger bearings can carry more weight because they have more contact area. If the parts fit well and are made carefully, the bearing lasts longer and works better. These ideas are important for radial bearings terminology.

Thrust Bearing Parts

Thrust bearings look different from radial bearings. They are made to handle forces that push along the shaft. These bearings have flat or grooved raceways. The rolling elements can be balls or rollers. They are set up to hold strong forces in one direction. The cage keeps the balls or rollers apart and lowers friction. Some thrust bearings use needle rollers to hold more weight in a small space. Others use balls for smoother and faster turning. Lubrication channels help the bearing work well under heavy loads. These features are important in thrust bearings terminology.

Thrust bearings are best when you need to hold forces that go along the shaft, not across it.

Load Directions

Roller bearings can hold different kinds of forces. It depends on how they are made. Radial bearings hold forces that push sideways to the shaft. Thrust bearings hold forces that push along the shaft. Some bearings, like tapered roller bearings, can hold both kinds of forces. The way you set up the bearings, like in X or O shapes, changes how they hold weight from different ways. The contact angle also changes how much force the bearing can hold along the shaft. When you pick a bearing, think about the way and size of the force.

If you want help picking the right bearing, we at TFL Bearings are ready to help you.

Learning roller bearing terminology helps you make smart choices. It keeps your machines working well. When you review these words, you get better at fixing problems. You can stop failures before they happen. You also get better at taking care of and fixing machines.

- Using the right words helps you find problems early. It lets you use the best ways to fix things.

- Going over the terms helps you see design changes. It helps you not make common mistakes.

- Using the correct words in real life helps you grow as an engineer.

You can find more ways to learn in the table below:

| Resource Type | Description |

|---|---|

| Technical Toolbox | Charts, guides, eBooks, webinars, conversion charts, and failure analysis for all bearing types. |

| Online Courses | Interactive lessons on bearing basics and how they are made. |

| Maintenance Training | Hands-on classes for putting in, checking, and finding damage. |

| Blog and Videos | Posts and videos with tips and more knowledge. |

We at TFL Bearings have guides, support, and many tools to help you learn about roller bearings. Try our resources and let us help you become an expert.

FAQ

What is the main job of a roller bearing?

A roller bearing helps parts move smoothly by reducing friction. You use it to support heavy loads and keep machines running longer.

What does “clearance” mean in a bearing?

Clearance is the small space inside a bearing. This space lets the rollers move freely. You need the right clearance for smooth and safe operation.

What happens if you use the wrong bearing type?

If you pick the wrong bearing, your machine may wear out faster or break. You might see more noise, heat, or even sudden failure.

What is the difference between a shield and a seal?

A shield keeps out dust and dirt but does not fully block liquids. A seal keeps out both dirt and liquids, protecting the inside of the bearing better.

What should you check before installing a bearing?

You should check that the shaft and housing are clean and the right size. Make sure you have the correct bearing type and add the right lubricant.

Need more help? We at TFL Bearings are ready to answer your questions and guide you to the best roller bearing solutions.