Roller ball caster wheels are a vital yet often overlooked component in countless mechanical, industrial, and commercial systems. These small but powerful devices provide multidirectional mobility and load-bearing capacity, making them essential for applications that require both flexibility and control. From mobile workstations to hospital carts and high-capacity industrial machinery, roller ball bearing casters play a key role in enabling smooth operation and enhancing productivity.

In this guide, we explore how roller ball caster wheels work, what factors to consider when choosing them, and where they are most effectively applied.

Understanding Roller Ball Bearing Casters

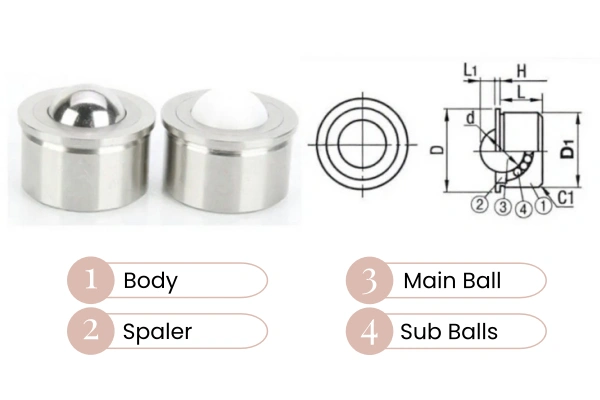

Roller ball caster wheels are a type of swivel caster featuring a ball-shaped rolling mechanism housed within a bearing race. This design allows for 360-degree movement, enabling users to push, pull, or rotate equipment in any direction with minimal resistance.

The heart of these casters lies in the ball bearing structure. Unlike traditional wheel-based casters, roller ball bearing casters reduce rolling friction to a minimum, allowing heavier loads to be moved with greater precision and less effort. Their compact design also makes them well-suited to tight spaces where maneuverability is crucial.

Benefits of Roller Ball Bearing Casters

Choosing roller ball bearing casters over other types of casters offers several performance advantages:

Omnidirectional Mobility

The spherical ball allows smooth movement in any direction, which is especially useful in confined environments where turning space is limited.

Reduced Operator Fatigue

Thanks to the reduced friction and smooth rotation, workers exert less effort when moving heavy equipment, reducing physical strain and the risk of injury.

Compact and Low-Profile Design

These casters can be integrated into low-clearance systems without compromising on performance, making them suitable for delicate or space-limited designs.

Durability and Longevity

High-quality materials and precision ball bearings ensure excellent wear resistance, even under continuous or heavy-duty use.

Key Considerations for Selection

Choosing the right roller ball caster wheels requires a careful assessment of several factors to ensure optimal performance and longevity.

Load Capacity

First and foremost, determine the maximum weight the casters will need to support. Each caster has a specific load rating, and exceeding this can lead to premature wear or failure. Always calculate the total weight of the item plus any potential load it might carry, then divide by the number of casters used to find the minimum required capacity per caster. It’s often wise to choose casters with a slightly higher capacity than strictly necessary for added safety and durability.

Material and Environment

The material of the caster ball and housing should align with the operating environment.

- Steel balls are common for general purposes, offering good strength and wear resistance.

- Nylon or plastic balls are suitable for sensitive floors or applications requiring non-marking properties, though they generally have lower load capacities.

- Consider the presence of moisture, chemicals, extreme temperatures, or abrasive surfaces. Specific materials, like stainless steel, might be necessary for corrosive environments.

Mounting Type

Roller ball casters come with various mounting options:

- Plate mounts are common, providing a broad base for secure attachment.

- Stem mounts offer a more compact solution, often used for furniture.

- Threaded stem mounts allow for height adjustment. Ensure the mounting type is compatible with your application’s design.

Swivel vs. Fixed Casters

While roller ball bearing casters are typically used for their full-range swivel capability, combining them with fixed-direction casters can offer better directional control in some cases—such as in long, narrow corridors.

Size and Clearance

The diameter of the ball and the overall height of the caster will impact stability and clearance. Larger balls generally distribute weight better and roll more smoothly over minor imperfections. Ensure there’s adequate clearance for the caster to operate freely without obstruction.

Key Applications of Roller Ball Bearing Casters

The versatility of roller ball caster wheels makes them suitable for a diverse range of applications across various industries.

Furniture and Retail Displays

In furniture, they enable easy rearrangement of sofas, tables, and cabinets. For retail, they allow for flexible and dynamic store layouts, making it simple to reconfigure display cases and racks. Their smooth movement protects flooring from scratches and scuffs.

Office and Institutional Furniture

Roller ball casters are increasingly used in ergonomic furniture systems such as height-adjustable desks, AV carts, and conference tables.

Automation and Conveyor Systems

In industrial settings, roller ball casters are integral to automation and material handling. They are frequently used in ball transfer units on conveyor belts, allowing heavy or awkwardly shaped items to be easily rotated, pushed, and guided in any direction, significantly increasing efficiency in assembly lines and packing areas.

Medical and Laboratory Equipment

The need for precise, quiet, and easily movable equipment is paramount in medical and laboratory environments. Roller ball casters provide the necessary agility for moving sensitive instruments, diagnostic machines, and hospital beds, ensuring quick positioning and minimal disruption.

Conclusion

Roller ball caster wheels are a powerful solution for any application that demands fluid motion, high load capacity, and compact design. Their unique construction enables 360-degree movement while reducing friction and wear, making them a go-to choice for both lightweight maneuverable systems and heavy-duty industrial setups. From choosing the right material and mounting style to understanding load requirements and environmental conditions, selecting the proper caster is essential for safety, performance, and longevity.

At TFL Bearings, we specialize in providing high-precision roller ball bearing casters tailored to your specific needs. Whether you’re engineering new equipment or upgrading existing systems, our wide range of caster solutions is designed to keep your operations rolling with efficiency and reliability. We’re here to support your success with expert guidance, premium materials, and responsive service—because mobility should never be an afterthought.

Explore our range today and discover how the right casters can transform your movement.