As discussed in our previous article, mechanical components such as bearings can generate vibration energy due to friction, impact, or deformation. This energy is then transmitted through the mechanical structure—such as the motor shaft or housing—where it can cause resonance or secondary vibrations, ultimately leading to audible noise.

When these vibrations propagate through surrounding structures and cause the air to oscillate, the result is airborne noise. The larger the vibrating surface area, the higher the noise radiation efficiency. Similarly, lower surface stiffness makes the structure more susceptible to excitation, turning it into a “sound amplifier.”

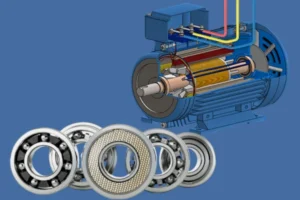

In electric motors, bearings are often a primary source of inherent noise—even when there is no fault present. This type of noise, often subtle yet noticeable, can be measured using standards such as GB/T 24610 and is especially important in high-precision, high-performance applications. Here’s a comprehensive guide on how to minimize bearing noise, focusing on design, selection, and application.

Reduce Noise Through Optimized Bearing Design

Cage Pocket Optimization

By optimizing the geometry of the cage pockets, we can reduce impact between the rolling elements and the cage, which significantly cuts down vibration-induced noise. TFL Bearings offers multiple cage designs tailored for high-speed, low-noise applications.

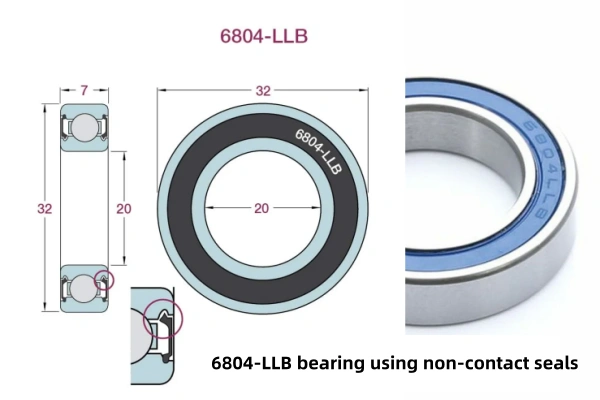

Low-Friction Sealing Structure

Seals play a critical role in both performance and acoustics. Using non-contact seals helps prevent contamination while minimizing friction, reducing both mechanical vibration and heat generation.

Cage Guidance Control

Cages guided by rolling elements often suffer from instability, particularly at high rotational speeds. A more stable alternative is a ring-guided cage, which ensures more consistent rotation and lower operational noise.

Select Advanced Materials to Reduce Vibration

PEEK Composite Cages

Metal cages tend to produce higher impact noise due to their rigidity. At TFL, we offer PEEK (Polyether ether ketone) composite cages, which provide excellent wear resistance while significantly reducing impact noise. These cages are ideal for high-speed and quiet-running electric motor systems.

Avoid Thin Stamped Steel Cages

While lightweight and cost-effective, stamped steel cages can deform under high-speed conditions. This deformation introduces vibration and excitation, which elevates the noise level. Instead, opt for higher-stiffness designs when operating at high speeds.

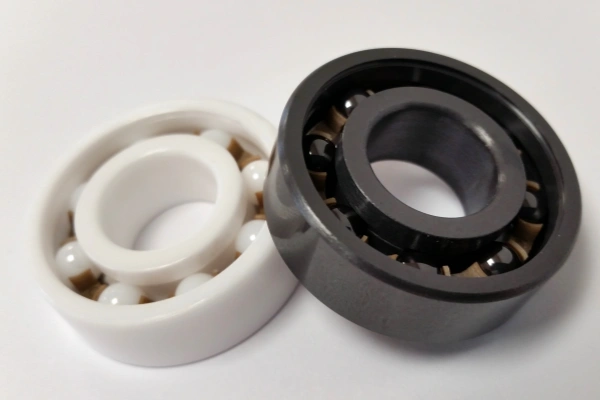

Use Ceramic Rolling Elements

Silicon nitride (Si₃N₄) ceramic balls are lighter than steel, reducing centrifugal force and suppressing vibration. This is especially beneficial for high-speed applications where NVH (Noise, Vibration, Harshness) characteristics are critical—such as electric vehicles or precision motors.

Manufacturing Precision: Control Surface Quality and Geometry

Superfinishing the Raceway

By applying ultra-precision finishing, the raceway surface roughness can be controlled to Ra ≤ 0.05 μm, compared to typical values of 0.1 μm. This reduces micro-friction and suppresses vibration, thereby reducing noise.

Apply Advanced Coatings

Applying coatings to bearing rings and rolling elements reduces the coefficient of friction, minimizes wear, and absorbs vibration. Coatings also improve corrosion resistance and are ideal for low-noise environments.

Matched Rolling Element Sizes

At TFL, we use high-precision diameter sorting to ensure the size difference among balls is less than 0.5 μm. This ensures uniform load distribution, reducing localized vibration that can contribute to tonal noise.

Interrupt the Noise Transmission Path

Noise isn’t just about generation—it’s also about transmission. Even with a low-vibration bearing, poor mounting or design can result in amplified noise.

Use Vibration Isolators

Installing anti-vibration mounts or isolators between the motor and machine frame can reduce vibration transmission by up to 90%, especially effective in HVAC systems and large motors.

Install Flexible Couplings

Couplings that absorb misalignment and mechanical shock help prevent shaft vibration from reaching the motor housing, reducing structural resonance.

Choose Low-Noise Greases

Specialized lubricants—engineered for acoustic performance—can dampen high-frequency vibrations within the bearing, cutting down emitted noise in high-speed electric motors.

Optimize Bearing Application for Electric Motors

Prefer Ball Bearings Over Roller Bearings

Ball bearings typically generate less noise due to point contact compared to the line contact of roller bearings. They are ideal for most small-to-medium electric motors.

Choose Smaller Diameters and Lightweight Series

Noise level increases with bearing size. A smaller bearing diameter typically results in lower vibration amplitude and hence lower noise output. Lightweight bearing series are also preferred for this reason.

Ensure Proper Fit and Mounting

A secure fit between the bearing and housing/shaft reduces unwanted movement and structural vibration. Increasing bearing seat rigidity can also reduce the overall sound pressure level.

Manage Bearing Clearance

Radial clearance plays a critical role in bearing noise:

- Excessive clearance results in less stable rotation, leading to higher vibration and noise.

- Insufficient clearance may cause bearing seizure due to thermal expansion or preload.

The ideal is to maintain a minimal but safe operating clearance. When large clearance is unavoidable (e.g., due to thermal expansion), preload using a spring washer can maintain effective low working clearance and reduce vibration.

Real-World Application Examples

Electric Motor Noise Reduction

At a small but ambitious motor manufacturing company in southern Germany, Lena, a lead R&D engineer, faced a recurring challenge. Her team had just developed a compact electric motor for a next-gen ventilation system—sleek, energy-efficient, and powerful. But during acoustic testing, one issue kept surfacing: excessive noise.

The motor passed all functional checks. It was mechanically sound, the electronics were clean, and the design was solid. Still, the noise level hovered 6 decibels above the target, jeopardizing a potential contract with a luxury appliance brand.

Lena turned to TFL Bearings for a second opinion. After analyzing the application, TFL’s team recommended a subtle but powerful change: refine the groove surface finish on the deep groove ball bearings. The existing Ra was 0.1 μm—not bad, but not ideal for ultra-low-noise motors.

With TFL’s help, they sourced bearings polished to Ra 0.04 μm and re-ran the tests.

The result? A 6 dB drop in noise. The new version ran almost silently. Lena smiled when she heard the final prototype—it was like the motor was whispering. The contract went through.

Automotive Wheel Hub Bearing

Meanwhile, in Japan, an automotive startup developing electric vehicles was struggling with high-frequency vibration in their wheel hub assemblies—especially at highway speeds. Customers reported a slight buzzing noise, and the engineering team suspected the steel balls inside the hub bearings were to blame.

TFL Bearings offered a bold alternative: ceramic rolling elements made of silicon nitride (Si₃N₄). Lightweight and ultra-hard, these balls could reduce centrifugal force and smooth out the vibration curve.

The team replaced the steel balls with TFL’s ceramic versions in a test batch. After extensive road testing, the verdict was clear: noticeably improved NVH performance, especially during long-distance cruising.

One test driver summed it up best: “It doesn’t feel like driving an EV. It feels like gliding.”

Thanks to TFL’s solution, the startup launched its new model with confidence—and an even quieter ride.

TFL Bearings: Your Partner in Noise Reduction

At TFL Bearings, we believe that controlling vibration and noise requires a holistic approach—from design and manufacturing to lubrication and application. We are committed to developing bearings that meet the highest standards of ultra-quiet operation and high reliability.

While the best solution depends on your specific operating conditions (speed, load, temperature), our engineering team is here to help you select the optimal bearing for your needs.

Ready to find the right bearing solution for your quiet motor design? Contact us today to discuss your project.