Industrial pump insulated bearings show clear improvements in 2025. Insulated bearings stop electrical arcing and wear in pumps, compressors, and generators. These insulated parts help machines last longer and need less fixing. Some main benefits are:

- Better reliability because they stop electrical damage in pumps and compressors.

- Insulated bearings help with better cooling and less noise in pump systems.

- Using insulated materials means less fixing and better work results.

- Regular checks and firmware updates keep things working well.

Insulated bearings are still very important for big machines. We at TFL Bearings are here to help with your insulated bearing needs.

Key Takeaways

- Insulated bearings stop machines from getting electrical damage. This helps pumps, compressors, and generators last longer. It also helps them work better. Using insulated bearings means machines break down less often. This lowers repair costs and saves money. It also makes machines more reliable. Picking the right insulated bearings is important. Installing them the right way is also important. Taking care of them often keeps machines working well. This stops expensive problems from happening. New things like ceramic coatings help insulated bearings last longer. Smart sensors make them easier to check. These things also help save energy. More companies are starting to use insulated bearings. This helps them be safer and protect the environment. It also helps machines work better.

Insulated Bearings Overview

What Are Insulated Bearings

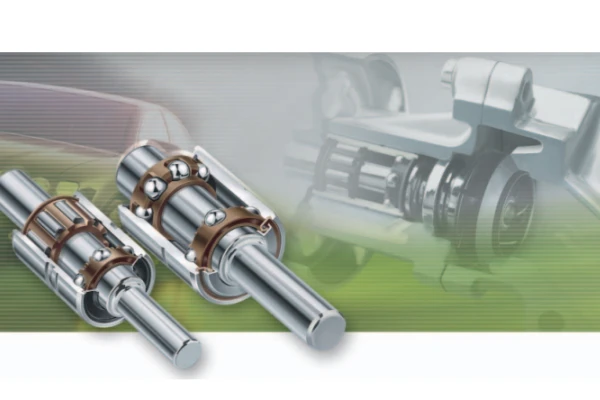

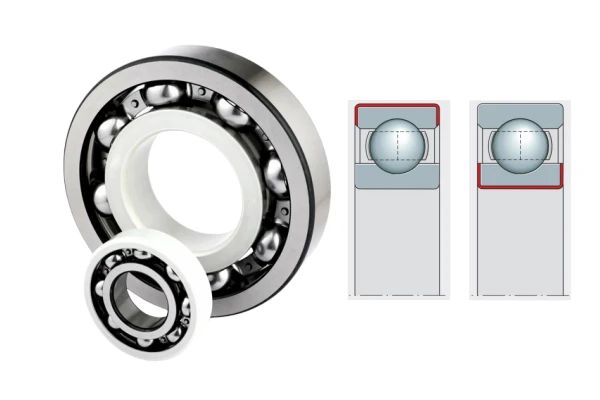

Insulated bearings are very important in today’s machines. They use special materials and coatings to stop electricity from passing through. These bearings are different from regular ones because they have ceramic coatings or ceramic rolling parts. The most common coating is alumina, which is sprayed on and can be thick or thin. Some bearings use PPS polymer coatings, which block electricity very well and can handle high voltage. Ceramic rolling parts made from silicon nitride are strong and stop electricity too.

Manufacturers put the insulation on either the inside or outside ring of the bearing. This does not change how the bearing works or its size. Ceramic rolling parts also last a long time and can handle heat, so they work well in tough places. Regular bearings do not have these features and cannot stop damage from electricity. Insulated bearings help machines last longer by protecting the grease, rolling parts, and raceways from electric harm.

Note: Insulated bearings are the same size as regular bearings, so you can easily replace them.

Why Use Insulated Bearings

Many factories use insulated bearings for different reasons. These bearings keep electricity from moving and stop damage from happening. They help machines run smoothly and safely. Insulated bearings can handle up to 1000V DC, even when the voltage is high. They also work well in hot and wet places, so they last longer.

Some main benefits are:

- Machines break down less and need fewer repairs, so you save money.

- They block water and moisture, so machines work better.

- They stop electric damage, like shaft currents and corrosion, which can make machines wear out faster.

Machines work better and last longer, even in hard jobs like wind turbines, trains, and big motors.

Insulated bearings are used in many machines. You can find them in generators, motors, compressors, pumps, and other important equipment. They are used more and more in power plants, chemical factories, and mines. These bearings help save energy and make machines quieter and smoother.

Insulated bearings can be made to fit different loads, speeds, and places. This helps them work their best and last a long time in many jobs.

We at TFL Bearings can help you with any insulated bearing needs. Contact us to learn how our bearings can make your machines work better and cost less to fix.

Industrial Pump Insulated Bearings Application

Insulated bearings are very important in many industries. They keep machines safe from electrical harm and help them work better. The main places they are used are pumps, compressors, and generators. Insulated bearings have ceramic coatings or ceramic rolling parts to stop bad currents. This keeps the equipment from getting damaged and helps it last longer. Many companies pick insulated bearings because they work well and save money.

Application in Industrial Pumps

Industrial pumps often use variable frequency drives. These drives can make unwanted electrical currents. Insulated bearings stop these currents from going through the pump. This keeps the pump safe from damage and lessens wear. Pumps with insulated bearings work better and last longer. Power plants and chemical plants use these bearings to keep pumps working well. Insulated bearings are also good for pumps that do not use oil. Using these bearings in pumps means fewer problems and lower repair costs.

Application in Compressors

Compressors have problems like pumps do. Electrical currents can hurt bearings and make compressors work worse. Insulated bearings stop this by blocking the electricity. They use strong ceramic materials for insulation. This helps compressors run quietly and smoothly. In chemical plants, insulated bearings help compressors do hard jobs. Using insulated bearings in compressors makes them more reliable and cuts down on stops. Many companies now use insulated bearings in their important compressors.

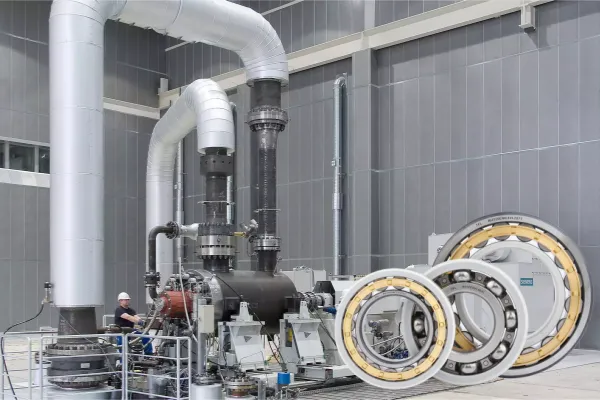

Application in Generators

Generators work in tough places. They need bearings that can handle heavy loads and electrical stress. Insulated bearings give this protection. They stop electrical currents from hurting the inside of the generator. In power plants, insulated bearings help keep things running well. They also lower the chance of problems from electrical discharge. Many factories use insulated bearings in generators to keep them working all the time. Using insulated bearings in generators helps them last longer and work better.

Tip: Picking the right insulated bearing for each job gives the best results in industry.

We at TFL Bearings can help you with all your insulated bearing needs. Contact us to find the best bearings for your machines and make them work better.

Case Studies

Power Generation Pumps

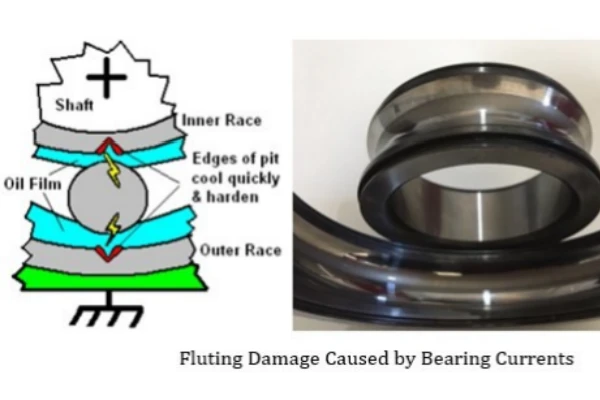

Power plants need pumps to move water and steam. In 2025, many plants had pump problems. Electrical currents went through regular bearings. This caused pitting and fluting. Bearings wore out too soon. Maintenance teams had to fix pumps a lot. They faced sudden shutdowns and high repair bills.

Engineers used insulated bearings to fix these problems. They picked bearings with ceramic coatings. These coatings stopped electrical currents. Installing the bearings took careful work. Teams checked the alignment and insulation often. They also watched vibration and temperature for early warning signs.

After using insulated bearings, pump failures dropped a lot. Pumps worked longer before needing repairs. There were fewer emergency stops and lower costs. Pumps became more reliable. This helped power plants make electricity without problems.

Note: Insulated bearings in power plant pumps stop electrical damage and help equipment last longer.

Petrochemical Compressors

Petrochemical plants use compressors to move gases and liquids. Before insulated bearings, compressors had many problems:

- Coolant ports got blocked and caused overheating.

- Oil feed holes got clogged, so bearings did not get oil.

- Shafts bent and touched rotors, making vibration and shutdowns.

- Old oil made varnish inside bearings, trapping heat.

- Water in oil tanks made steam and cracked bearings.

- Static electricity in oil filters added more risks.

Engineers put in insulated bearings with ceramic coatings. They also made oil filters better and used good lubricants. Sensors checked temperature, vibration, and oil quality. Teams did regular checks and planned repairs.

The changes worked well. Compressors ran cooler and smoother. There were fewer shutdowns and less damage from electricity. Oil stayed cleaner, and bearings lasted longer. Plants saved money on repairs. Workers could focus on making products, not fixing machines.

Tip: Checking bearings often and using good oil helps insulated bearings work best in petrochemical compressors.

Manufacturing Generators

Factories need generators to power machines and lights. Old bearings in generators failed from stray electrical currents. This caused noise, shaking, and costly stops.

Factories switched to insulated bearings made for generators. These bearings had ceramic rolling parts. The ceramic stopped electricity from passing through. Teams installed them carefully and checked the fit. Maintenance crews looked for wear and kept bearings clean.

After the change, generators ran quieter and smoother. Insulated bearings stopped electrical damage. Generators lasted longer and had fewer problems. Factories had fewer stops and lower energy bills. Production lines kept running.

Callout: Insulated bearings in factory generators help machines run steady and need less fixing.

We at TFL Bearings help companies get these good results with our insulated bearings. Contact us to learn how we can make your machines work better and cost less to fix.

Benefits of Insulated Bearings

Reliability Improvement

Insulated bearings help machines work better and last longer. They use special coatings and ceramic parts to block electrical currents. This keeps pumps, compressors, and generators safe from damage. Motors with variable frequency drives can have electrical problems. Insulated bearings stop these problems and help machines run longer. The LSBT-Net framework shows these bearings help find faults faster. This means machines break down less often. Insulated bearings also lower vibrations, so machines run smoother. When companies use insulated bearings, their pumps work better and last longer.

- Insulated bearings block current and stop electrical damage.

- They help machines use less energy and work better.

- Finding problems early means fewer breakdowns.

Tip: Insulated bearings help machines keep working, even when things get tough.

Maintenance Reduction

Insulated bearings mean machines need less fixing. They protect parts from electrical harm, so they last longer. Workers spend less time fixing and more time making things. These bearings keep oil clean and lower wear. This means machines stop less and have fewer surprise problems. With less fixing, companies save money and work better. Insulated bearings also help save energy by keeping machines running well.

- Fewer repairs and lower fixing costs.

- Bearings and pumps last longer.

- Machines stop less for fixing.

Note: Checking bearings often and using good oil helps them work best.

Operational Stability

Insulated bearings help pumps, compressors, and generators work steady. They can handle heavy work and hard places. The coatings stop electrical problems and keep machines running smooth. Pumps with these bearings use less energy and work better. Insulated bearings also lower noise and shaking. This makes work safer and products better. Companies using these bearings see machines work steady and do better.

- Machines work steady in all jobs.

- They use energy better and save more.

- Machines run well with less chance of breaking.

Callout: We at TFL Bearings help you get good energy use and steady work with our insulated bearings. Contact us for help and answers.

Selection and Maintenance Guide

Choosing Insulated Bearings

People in the industry pick insulated bearings by following steps. They look at where the bearing will be used. Things like heat, wetness, and chemicals matter for picking materials and oil. Next, they check how much weight and speed the bearing needs to handle. Roller bearings are good for heavy loads. Low-friction bearings are better for fast spinning. The insulation must stop electric current. This keeps motors and generators safe from damage. The size of the bearing must fit the machine. It should also be easy to take out and fix. People think about how long the bearing will last and how much fixing it needs. Strong bearings with seals keep out dirt and last longer. The type of insulation, like aluminium oxide or silicon nitride, depends on what the machine needs. Picking the right bearing for the job helps it work best. Radial bearings hold up loads from the side. Thrust bearings hold up loads from the end. Heat and oil needs also help people choose the right bearing.

Tip: Picking the best insulated bearing for each job helps machines work better and break down less.

Installation Tips

Putting in insulated bearings the right way stops them from breaking early. Teams follow the maker’s rules for putting them in straight. The area must be clean. Dirt can hurt the bearing. Workers use the right tools and are careful not to drop or hit the bearing. They use the right way to put the bearing on, like pressing or shrinking it on. Some mistakes are not cleaning the shaft, leaving paint, or using the wrong stuff at contact spots. Grounding rings should not go over keyways unless filled with epoxy putty. Conductive epoxy is better than non-conductive glue for screws. Metal touching metal is needed for good grounding. After putting in the bearing, teams check grounding with a meter. Seals or putting rings inside the housing help keep dirt out in messy places.

Note: Careful work when putting in insulated bearings helps them last longer and work better.

Maintenance Best Practices

Taking care of insulated bearings helps them work well. Teams use the right oil and add more at set times. Clean bearings keep out dirt and dust that can cause damage. Using the right tools to put in bearings stops stress and uneven wear. Teams check for wear, rust, noise, and shaking. Watching heat and noise helps find problems early. Tools like vibration checks and heat cameras show early signs of trouble. Bearings should stay in their box, in a clean, dry place, away from heat and wetness. Wearing clean gloves and using shields or seals keeps dirt out. A good plan for checking, oiling, cleaning, and fixing bearings helps them last longer and stop machines from breaking.

Callout: Checking and taking care of insulated bearings often helps stop costly breaks and keeps machines working well.

We at TFL Bearings help your team pick, put in, and take care of insulated bearings. Contact us for help to keep your machines running well.

Future Trends

Industry Adoption

Insulated bearings are being used more in many industries. Companies expect the market for insulated bearings to keep growing after 2025. Many things make this happen:

- More electric and hybrid vehicles need insulated bearings.

- Wind turbines and solar power projects need strong insulated parts.

- Factories with robots need bearings that protect against electricity.

- Experts think the market will grow by about 7% to 8.7% in the next years.

- New rules and green goals make companies use safer, eco-friendly materials.

- Smart sensors in bearings help watch them and fix problems before they break.

- Asia-Pacific, Europe, and North America use these bearings the most, but Latin America and the Middle East are catching up fast.

- Bearing makers work with IoT companies to make smart, new products.

Insulated bearings help companies save energy and work better. Safety and environmental rules make these bearings a top pick for many jobs.

Technology Innovations

New technology is changing insulated bearings. Makers want bearings to last longer and use less energy. The table below shows some new ideas in insulated bearings:

| Innovation Aspect | Description |

|---|---|

| Hybrid Technology | Ceramic balls stop electricity from hurting the shaft. |

| Durability | Less wear and damage means bearings last longer. |

| Material | Strong steel rings help bearings work well for a long time. |

| Quiet Operation | Bearings stay quiet, even in fast electric motors. |

| Plasma Ceramic Coating | A special layer on rings blocks at least 1000V AC/DC. |

| Cost-effectiveness | Ceramic coatings protect bearings and save money. |

| Application Suitability | Good for electric motors, wind turbines, and trains. |

| Smart Sensors | Sensors check bearings and warn if something is wrong. |

Insulated bearings now have better ceramic parts and smart sensors. These changes help machines use less energy and make bearings last longer. Plasma coatings and hybrid designs help bearings work well in tough places.

Tip: Companies that buy the newest insulated bearings have fewer machine problems and better results.

We at TFL Bearings give you the newest insulated bearings and expert help. Contact us to see how our bearings can help your machines use less energy and work better.

In 2025, many industrial companies keep picking insulated bearings because they work well. Insulated bearings stop damage from electric currents and help machines last longer. These bearings also make machines more reliable. They can handle very hot or cold places. Insulated bearings help lower noise and shaking. Companies have fewer problems and spend less money fixing machines with these bearings. Insulated bearings save energy and help the environment. You can find them in electric cars, wind power, pumps, and trains.

- Insulated bearings give:

- Great insulation for better machine work

- Good strength in hot and cold

- Less noise and less shaking

- Longer use and fewer problems

- High energy savings for lower costs

In the future, insulated bearings will use more recycled stuff and smart tech. AI and IoT will help watch bearings all the time. New materials and coatings will help them last even longer. More people want these bearings in Southeast Asia, the Middle East, and Latin America. Green ideas and new tech help make better insulated bearings.

We at TFL Bearings give expert help and full service for insulated bearings. Our team helps you pick, put in, and take care of insulated bearings for any job. Contact us for strong insulated bearings and help to keep your machines working well.

FAQ

What problems do insulated bearings solve in industrial equipment?

Insulated bearings keep pumps, compressors, and generators safe from electrical harm. They stop electricity from moving through the bearing. This helps machines last longer and need fewer repairs. Insulated bearings also help machines work better in tough places.

How do insulated bearings differ from standard bearings?

Insulated bearings have special coatings or ceramic parts. These parts block electricity. Standard bearings do not have this kind of protection. Insulated bearings are best for machines with high voltage or changing speeds. They help stop bearings from breaking too soon.

Where should companies use insulated bearings?

Companies should use insulated bearings in pumps, compressors, and generators. These bearings protect machines in power plants, factories, and chemical plants. They also work well in wind turbines and trains. Any place with electrical danger can use insulated bearings.

How often should insulated bearings receive maintenance?

Insulated bearings need regular checks for wear, noise, and shaking. Teams should look at the bearing and change oil when needed. Clean places help insulated bearings last longer. Finding problems early keeps machines working and stops long breaks.

Can insulated bearings replace standard bearings without changes?

Insulated bearings are the same size as standard bearings. Teams can switch them without changing the machine. This makes upgrades simple. Insulated bearings fit pumps, compressors, and generators. They give better safety and last longer.

We at TFL Bearings help you pick, put in, and take care of insulated bearings for every job. Contact us for expert help and strong solutions.