You have many options when it comes to insulated bearing procurement for electric motors. Choosing the right insulated bearings is crucial to keep your equipment safe from electrical damage. Approximately 80% of bearing failures in AC motors result from electrical erosion, which can create small holes, degrade the lubricant, and cause rapid wear. Selecting the wrong insulated bearings can lead to overheating, noise, and equipment failure, resulting in costly repairs. To avoid these issues, focus on insulation strength, load capacity, and price during your insulated bearing procurement process. Consider your machine’s specific needs, usage conditions, and budget to ensure your equipment lasts longer.

Key Takeaways

- Insulated bearings keep electric motors safe from electrical harm. This helps motors last longer and need fewer repairs.

- Pick insulated bearings by looking at your motor’s size, speed, load, and where it works. This helps you get the best fit and performance.

- There are different kinds of insulated bearings. Resin coated and ceramic hybrid types have special benefits for different motors.

- You need to install insulated bearings the right way. Regular maintenance helps them work well and stops them from breaking early.

- Insulated bearings cost more at first. But they save money later because you will need fewer repairs and have less downtime.

Insulated Bearing Procurement

Why Insulated Bearings Matter

It is important to keep electric motors safe from electrical harm. Insulated bearings help with this job. They have a special layer that stops electric current from going through. Regular bearings do not have this layer. If current goes through a regular bearing, it can make small pits and cause damage. This can make the bearing wear out fast. Insulated bearings break the path of electricity. They stop electrical erosion from happening. This helps your motor last longer and saves money on repairs.

To stop current from moving between the bearing and shaft, bearings need insulation when: (a) the motor is 1005 hp (750 kW) or more; (b) the vendor says it is needed; or (c) the shaft voltage is over 100 mV for rolling element bearings or 200 mV for sleeve bearings. If insulation is used, both bearings should be insulated with a removable ground at the drive end or a double-insulated insert at the non-drive end. This lets you check insulation without taking the motor apart.

Insulated bearings help your equipment last longer. They also lower the number of breakdowns and repair costs. You can trust insulated bearings to keep your machines working well.

Common Applications

Insulated bearings are used in many fields. They are very important in electric motors, wind turbine generators, and railway traction motors. You will also find them in generators, submersible pumps, and wheel bearings for trams and electric trains. These bearings work well in tough places where stray currents can hurt equipment.

- Traction motors

- Stationary electric motors (medium and large sizes)

- Wind turbine generators

- Railway traction motors

- Submersible pumps

- Wheel bearings for trams and electric railway vehicles

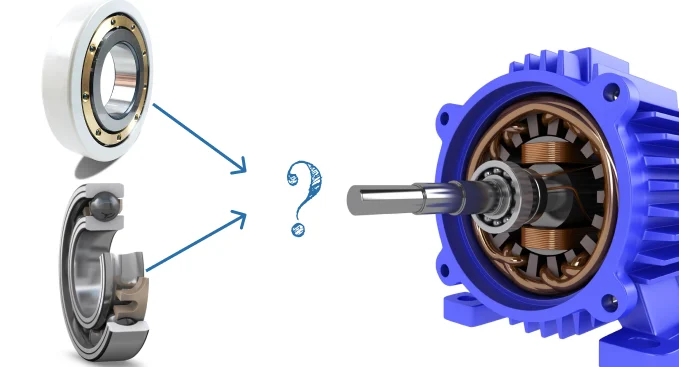

There are different types of electrically insulated bearings, like cylindrical roller bearings and deep groove ball bearings. These types fit into motor systems without needing extra insulation parts. When you choose insulated bearings, you help keep your equipment safe and working well.

Types of Motor Insulated Bearings

When you pick motor insulated bearings, you will see a few main types. Each type is made in a special way to stop electricity and keep your equipment safe.

Bearing Type | Construction Details | Insulating Method | Key Benefits and Applications |

|---|---|---|---|

| Resin Coated Bearings | Steel bearings with a resin coating on the outer ring | Resin coating forms an insulating barrier | Stops current, lasts longer; used in wind turbines, traction motors, variable speed motors |

| Ceramic Hybrid Bearings | Steel rings with ceramic (silicon nitride) rolling elements | Ceramic balls provide inherent insulation | Cools better, needs less oil, lasts longer; used in generator motors, wind energy |

| Electrically Insulated Bearings | Rings coated with silicon nitride and zirconium oxide | Ceramic coatings on rings for insulation | Works at high speed, low friction, high heat; stops corrosion |

Coated Bearings

Coated bearings are a good choice for electric motors. These bearings have a resin or ceramic layer on the outside ring. The layer keeps electricity from passing through. This protects the bearing from electrical erosion. Many companies use ceramic coated insulated bearings because they block current.

- Advantages:

- Less friction helps motors work better.

- Strong against wear, so they last longer.

- The tough coating means less fixing is needed.

- They work well even in hard places.

- Considerations:

- They cost more at first than regular bearings.

- Some coatings do not fit every job, so ask a supplier.

- You must install them right to keep the coating strong.

Special pps coated insulated bearings give more safety in harsh places. You can use them in motors that face wet air or chemicals. Ceramic coated insulated bearings are also good for wind turbines and water plants.

Ceramic Hybrid Bearings

Hybrid ceramic bearings have steel rings and ceramic balls. The ceramic balls do not let electricity pass. This stops current from moving through the bearing. That is why hybrid ceramic bearings are great for motors that need strong insulation.

- Ceramic balls block electrical currents.

- Hybrid ceramic bearings stop electrical wear and damage.

- These bearings make less friction and heat, so oil lasts longer.

- Hybrid ceramic bearings are lighter and harder than steel, so motors work better.

- You can find hybrid ceramic bearings in fast motors, wind turbines, and generators.

- Hybrid ceramic bearings last longer and need less fixing than regular bearings.

Ceramic coated insulated bearings and hybrid ceramic bearings both keep your motor safe. But hybrid ceramic bearings use the balls to stop current, not just the coating.

Insulating Materials

The materials in insulated bearings matter a lot for how they work. DuPont™ Vespel® polyimide is the most used material for motor insulated bearings. This material blocks electricity very well. Vespel® polyimide can take high heat and heavy weight without changing shape. Makers use it in bearing sleeves and inserts to make a thin but strong layer. Special pps coated insulated bearings use new plastics to fight chemicals and heat. Ceramic coated insulated bearings use silicon nitride and zirconium oxide layers for more safety. These materials help electrically insulated bearings last longer and work better in tough places.

Selection of Insulated Bearings

Picking the right insulated bearings keeps your electric motor safe. It also helps your equipment work well for a long time. You need to think about a few important things before you choose. The right choice stops electrical erosion. It also means less time fixing your motor and saves money.

Key Factors

When you pick insulated bearings, focus on these main points:

- Insulation properties: Make sure the bearing blocks electric current. This helps stop pitting and early failure.

- Motor speed: Fast motors make more heat and stress. You need bearings that can handle this.

- Load type: Think about how much weight the bearing holds. Also, think about which way the force goes.

- Operating environment: Dust, water, and temperature changes can hurt bearings. Sealed bearings help keep dirt out.

- Lubrication needs: The right oil or grease keeps bearings cool and smooth.

- Electrical insulation requirements: Motors with VFD or VSD need strong insulation. This helps them handle voltage spikes.

- Motor size: Big motors (frame size 225 or more) often need insulated bearings for extra safety.

Tip: Picking the right insulated bearings helps your motor last longer. It also means you spend less on repairs.

Load and Speed

You must match the bearing to your motor’s load and speed. The size and direction of the load matter. Heavy or changing loads need stronger bearings. If your motor is fast, the bearing gets hot quickly. You need a bearing that can take the heat and keep the oil working. Fast motors also make more friction. This can make bearings wear out faster if you pick the wrong kind.

How fast the motor runs changes how much heat the bearing makes. If it gets too hot, the oil can break down. Then the bearing might fail. Pick bearings that work in 71°C to 110°C. This is the usual range for electric motors. Motors with pulse modulation or high speed need insulated bearings. This helps stop damage like pitting or ribbing. Always check the speed rating. Make sure it fits your motor.

Environmental Conditions

Where your motor runs changes which insulated bearings you need. High heat can make some materials break down. In hot places, all-steel bearings work better. They do not get damaged by heat. Special greases and seals, like Viton™ or Teflon™, help bearings last longer.

Wet air and water can cause rust and hurt the oil. If your motor is in a wet place, use bearings with coatings that stop rust. Strong seals keep water and dirt out. This helps your bearings last longer. You can also use fans or heat sinks to keep the motor cool.

Step-by-Step Guide: How to Select Insulated Bearings

- Check Your Motor’s Requirements

Write down your motor’s speed, load, and size. Note if you use VFD or VSD. - Assess Insulation Needs

Decide if you need insulation to stop electric current. Ask, “when should insulated bearings be used?” If your motor uses VFD/VSD or is big, you likely need them. - Choose the Right Size and Type

Match the bearing size to your motor. Pick the type (coated, ceramic hybrid, etc.) that fits your load and speed. - Consider the Environment

Think about heat, wetness, and dust. Pick sealed or shielded bearings if you need more protection. - Select Lubrication and Seals

Choose oil and seals that work in your motor’s place. Fast or hot motors need special greases and seals. - Compare Costs

Balance your budget with the need for good bearings. The best bearings may cost more but save money later. - Consult an Expert or Supplier

Talk to a bearing supplier or expert. They can help you pick the right materials and coatings.

Note: Experts know how to match bearings to your motor. They help you avoid mistakes and keep your equipment safe.

You can use these steps to make picking insulated bearings easier. Always ask for help if you are not sure. Experts and suppliers know how to help you find the best bearings for your motor.

Installation and Maintenance

Proper Mounting

You must be careful when you put in insulated bearings. This keeps the insulation safe and helps them last longer. Here are some steps to follow:

- Use special tools to put in and take out bearings. These tools stop damage from too much force.

- Look at the bearing and its box before you start. Make sure the insulation is not broken.

- Check if the bearing fits the rotor shaft. Also, see if the outer ring fits the end cover hole.

- Use the right amount of oil or grease in the bearing. Too much or too little can make it slip or get too hot.

- Keep the insulation safe while you install the bearing. Do not let anything touch it that could break the insulation and cause electrical problems.

Tip: Always use strong insulation materials to keep the rotor in place. Do not use things that carry electricity, like carbon fiber. Glass-fiber resin is best for insulation shields.

When you put things back together, insulate bolts if you use insulation gaskets. Be careful so cables or grease do not touch the insulation layer.

Maintenance Tips

Doing regular checks helps your insulated bearings work better and saves money. Here are some good tips:

- Use the right grease and the right amount. Follow the maker’s plan for adding more grease.

- Keep the motor and bearings clean. Take away dust, dirt, oil, and extra grease so nothing gets damaged.

- Watch the bearing’s temperature. Check it with the safe range from the maker. If it gets too hot, stop the motor and look for problems.

- Keep water away from the bearings. Use grease that stops water and good seals. Make sure drains are open so water does not build up.

- Look for loose bolts and wires. Tighten bolts and cable connectors if they are loose.

- Make sure everything lines up right and the base is steady. If things are not lined up, the bearings will not last as long.

- Watch out for stray currents, especially if you use variable frequency drives. Stray currents can hurt the bearings and make them fail early.

Note: Sealed bearings already have grease and you cannot add more. They do not last as long as open bearings that you can grease again.

If you follow these tips, your insulated bearings will last longer and your machines will work well.

Alternatives and Additional Protection

Insulated Sleeves

Insulated sleeves add more safety for your motor bearings. These sleeves go between the bearing and the motor housing. They stop electric currents from moving through the bearing. Using insulated sleeves breaks the path for bad currents from variable speed drives or pulse width modulation. This helps stop pitting, too much heat, and early bearing failure.

- Insulated sleeves and insulated bearings work well together. They block both eddy currents and discharge currents.

- You often find these sleeves in motors with VSDs. The insulation keeps bearings safe from electric discharge machining (EDM).

- Some motors use bearing isolators as sleeves. These isolators seal the bearing housing and keep out dirt and water. They also keep oil inside, so bearings last longer.

- You do not have to change the motor housing to use these sleeves. They are simple to put in and do not need much care.

Tip: Use insulated sleeves with other protection to get the best results for your motor.

Grounding Devices

Grounding devices give another way to protect motor bearings from electrical harm. These devices, like shaft grounding rings, let stray currents safely go to the ground. You put the grounding ring on the motor shaft. The ring has special fibers that touch the shaft and carry the current away.

- Grounding devices send extra electric current away from important parts.

- They stop voltage from building up on the shaft. This keeps it from going through the bearings.

- You lower the chance of pitting, fluting, and noise in your bearings.

- These devices work well with insulated bearings, especially in big motors.

- You help your motor last longer and avoid expensive repairs.

Note: Grounding rings like AEGIS® cover the whole shaft and last longer than old carbon brushes.

You can also use shielded cables or common mode chokes for more safety. Shielded cables act like a cage and block bad currents, but they can cost more and be hard to put in. Common mode chokes soak up high-frequency currents at the source and stop damage before it gets to your motor.

Using insulated bearings, insulated sleeves, and grounding devices together gives the best protection from electrical harm. This keeps your equipment working well and helps it last longer.

Cost and Sourcing

Budget Considerations

When you want to buy insulated bearings for electric motors, you should think about how much money you can spend. Insulated bearings usually cost more than regular bearings. For example, a 6220/C3VL0241 insulated bearing with a ceramic coating might cost around $400. This higher price is because of the special materials and coatings that keep your motor safe from electrical problems.

There are many things that change how much you pay. You can see how these things affect your budget in the table below:

| Cost Factor | Influence on Budget and Selection |

|---|---|

| Material Cost | Different coating materials (ceramic, PPS) have different prices and work in different ways, which changes the first cost of the bearing. |

| Process Costs | Special spraying and coating steps make the bearing harder to make and cost more money. |

| Brand and Quality | Famous brands give better promises but cost more, so you have to think about your budget. |

| Application Scenarios | Bearings made for tough places (high speed, heat, or wet air) need special materials, which makes them cost more. |

| Maintenance Savings | If you pay more at first, you might save money later because the bearings last longer and you do not have to fix or replace them as often. |

You might pay more at the start for good insulated bearings, but you save money later. These bearings last longer and do not break as much. You also do not have to stop your machines as often.

Tip: Try to balance how much you spend at first with how much you can save later by needing less fixing and getting longer use from your bearings.

Quality Assurance

You want to make sure you get the best insulated bearings for your electric motors. Good bearings keep your machines safe and help them run well. Look for sellers who use strong materials and check their products carefully.

CeramicSpeed Industry is a trusted seller. Their insulated bearings use silicon nitride ceramic balls. These balls stop electricity from going through, so your motor does not get damaged. You can use these bearings in hard jobs like wind turbines or fast motors. CeramicSpeed has many kinds, like deep groove ball bearings and cylindrical roller bearings. Each bearing already has oil, so it is quiet and lasts a long time.

If you pick a good seller, you get bearings that last longer and work better. This means you do not have to worry as much about things breaking and you can trust your machines more.

Picking the right insulated bearings keeps your motor safe from electrical damage. This also helps your motor last longer. You will spend less money fixing things and your machines will stop less often. Your equipment will work better and not break down as much. Always think about what your machine needs, where it works, and how you put in the bearings. If you need help, talk to TFL Bearings. Their team can help you find the best insulated bearings for your job.

FAQ

What is the main benefit of using insulated bearings in electric motors?

Insulated bearings keep your motor safe from electrical harm. This means you do not have to pay for big repairs. Your equipment will last longer and work better.

How do you know if your motor needs insulated bearings?

See if your motor uses a variable frequency drive or has high power. If you notice bearing damage or strange sounds, you may need insulated bearings.

Can you install insulated bearings yourself?

You can put in insulated bearings if you follow the maker’s steps. Use the right tools and be gentle with the insulation layer. If you are not sure, ask an expert for help.

Do insulated bearings require special maintenance?

Insulated bearings do not need special care. Keep them clean, use the right grease, and look for damage. Checking them often helps you find problems early.