Comparing Accuracy and Speed in Ball Bearings

Explore key differences between high precision and high speed ball bearings.

| Features | High Precision Ball Bearings | High Speed Ball Bearings |

|---|---|---|

| Primary Design Focus | Emphasize extreme accuracy and tight tolerances. | Prioritize stability and performance at fast rotations. |

| Speed Capability | Moderate speed; not for extreme RPMs. | Excellent speed; built for high RPM operation. |

| Accuracy Level | Very high accuracy with minimal vibration. | Good accuracy optimized for stable rotation. |

| Load Capacity | High; supports radial and axial loads. | Moderate; optimized for speed over heavy loads. |

| Material Composition | Chrome steel with advanced coatings. | Hybrid ceramic, stainless steel, and special alloys. |

| Durability | Long life in controlled, clean environments. | Long life at high speeds with proper lubrication. |

| Noise and Vibration | Low noise and vibration for precision tasks. | Reduced noise and vibration at high speeds. |

| Typical Applications | Robotics, medical devices, aerospace, semiconductor manufacturing. | Motors, turbines, compressors, fans, machine tools. |

| Cost Consideration | Higher cost due to advanced materials and design. | Moderate to high cost depending on materials. |

Ball bearings play a vital role in many machines. High Precision Ball Bearings focus on extreme accuracy and tight tolerances. High speed ball bearings, on the other hand, emphasize stability and performance at fast rotations. Selecting the right ball bearings affects how well equipment runs. Some ball bearings offer better accuracy, while others allow for higher speeds. Engineers must consider which ball bearings best match their needs. The right choice of ball bearings improves reliability and efficiency.

Key Takeaways

- High precision ball bearings offer very accurate movement with tight tolerances, reducing vibration and noise in machines.

- High speed ball bearings excel at stable performance during fast rotations, handling heat and friction to last longer at high speeds.

- Material choices like chrome steel and hybrid ceramics affect bearing durability, speed, and wear resistance.

- Choosing the right bearing depends on the machine’s needs for accuracy, speed, load, and environment.

- Consulting experts and considering factors like load, speed, and conditions ensures the best bearing choice for reliable machine operation.

High Precision Ball Bearings

Definition and Characteristics

High precision ball bearings deliver outstanding accuracy and tight tolerances. These ball bearings use advanced manufacturing to achieve high accuracy and smooth rotation. Precision levels often reach ABEC 5, 7, or 9, which means the bearings have very little variation in size and shape. This high level of precision allows machines to run with less vibration and noise. Radial ball bearings and angular contact bearings both appear in high precision applications. These bearings support both radial and axial loads, making them versatile for many uses.

A table below shows the typical life expectancy of high precision ball bearings in different machines:

| Type of Machine | Typical Life in Hours of Operation |

|---|---|

| Instruments and apparatus used infrequently (e.g., demonstration apparatus) | ~500 |

| Aircraft engines | 500 – 2,000 |

| Machines for short or intermittent service (e.g., hand tools, farm machinery) | 4,000 – 8,000 |

| Machines for intermittent service with high dependability (e.g., conveyors) | 8,000 – 12,000 |

| Machines for 8-hour service (e.g., cranes, blowers) | 20,000 – 30,000 |

| Machines for continuous 24-hour operation (e.g., pumps, electric motors) | 40,000 – 60,000 |

| Machines for continuous 24-hour service with high dependability | 100,000 – 200,000 |

Common materials and designs

Manufacturers often use high carbon chrome steel, such as SAE 52100, for high precision ball bearings. This steel provides high hardness and toughness, which improves wear resistance and extends fatigue life. Reducing impurities in the steel, like oxide and Ti(C,N) inclusions, helps prevent early failure and increases durability. Some high precision bearings use advanced coatings, such as Polyamide-Imide with solid lubricants, to reduce friction and improve performance during tough conditions. Many designs combine steel shells with aluminum or bronze linings and thin overlays. These layered structures help optimize load capacity and wear resistance. Angular contact bearings and radial ball bearings both benefit from these material choices.

Applications

High precision ball bearings appear in many industries that require high accuracy and reliability. These include industrial automation, aerospace, automotive, wind energy, medical devices, and semiconductor manufacturing. The market for these ball bearings reached USD 329 million in 2023 and is expected to grow to USD 454 million by 2030. This growth comes from the need for lightweight, high-performance components and increased automation. Angular contact bearings and radial ball bearings both play key roles in these sectors. High precision bearings offer superior durability, wear resistance, and temperature tolerance, making them ideal for demanding environments.

High Speed Ball Bearings

Definition and Characteristics

High speed ball bearings are designed for machines that need to run at high operational speed with minimal friction and heat. These ball bearings follow strict standards, such as ISO 281, which defines how to measure dynamic load ratings, fatigue limits, and static load ratings. Manufacturers use these standards to ensure that ball bearings can handle the demands of high-speed applications. The dynamic load rating shows how much load a bearing can carry while spinning fast for a long time. The fatigue load limit tells how much stress the bearing can take before it starts to wear out. Ball bearings in this category often use advanced designs to reduce vibration and noise, which helps machines run smoothly and last longer.

Note: The L10 life rating estimates how long 90% of a group of ball bearings will last under certain loads and speeds. This helps engineers choose the right bearing for each job.

Common materials and designs

Manufacturers select materials and designs that help ball bearings perform well in high-speed applications. The table below shows some common choices:

| Aspect | Details |

|---|---|

| Materials | AISI 52100 chrome steel, 440C stainless steel, Cronidur®30, M50 steel, hybrid ceramic-steel combinations |

| Cage/Retainer | Steel, brass, polyamide, PEEK, phenolic; designs include ribbon, tab, crown, solid |

| Lubrication | Greases (sodium, calcium, lithium, aluminum-lithium, polyurea) for different temperature ranges |

| Clearance | Internal clearance is critical; zero clearance is best for high speeds |

| Seals | Shields or non-contact seals allow higher speeds |

Hybrid ball bearings, which use ceramic balls and steel races, show better performance and longer life at high speeds. Engineers also use finite element analysis to adjust the thickness of races and the size of balls. These changes help balance flexibility and strength, making the bearings more reliable in high-speed applications.

Applications

High speed ball bearings play a key role in many industries. Pumps and compressors often use angular contact bearings because they can handle both radial and axial loads at high speeds. In semiconductor equipment, caged ball bearings help machines run non-stop for long periods without much maintenance. This reduces downtime and saves money. Hybrid bearings with ceramic balls work well in high-speed applications, such as machine tools and turbines, because they last longer and resist wear better than all-steel bearings. Radial ball bearings also appear in motors and fans where high rotational speed is important. Angular contact bearings are popular in robotics and aerospace, where both speed and precision matter. These examples show how ball bearings support reliable, efficient operation in demanding environments.

Key Differences

Design Focus

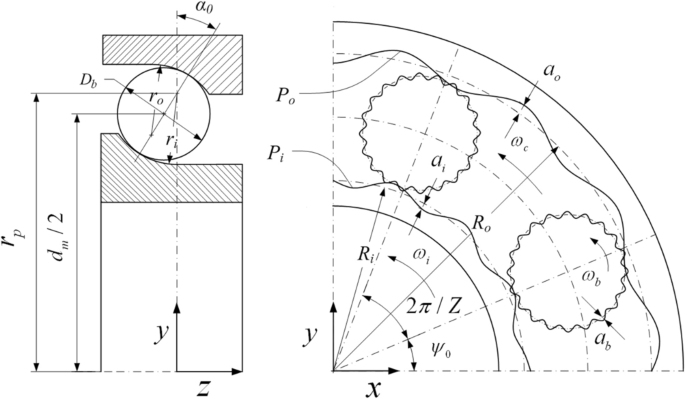

High precision ball bearings and high speed ball bearings have different design priorities. High precision ball bearings focus on accuracy and tight tolerances. Engineers use advanced models to analyze the design of these bearings. For example, P2 grade aerospace bearings require careful calculation of radial and axial runouts. These calculations help reduce errors and improve rotary accuracy. The rotary accuracy often exceeds the raceway error by an order of magnitude. This means the bearing can spin with almost no wobble. Designers pay close attention to raceway tolerance values and error equalization. These steps ensure the bearing meets strict standards for precision.

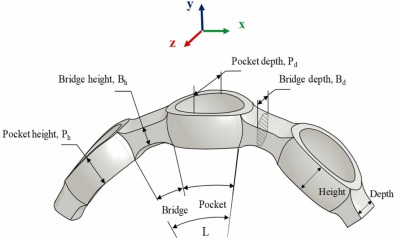

In contrast, high speed ball bearings focus on stability and performance at high operational speed. Engineers use computational fluid dynamics (CFD) to study how cage geometry affects drag losses. At speeds up to 6000 rpm, cage drag becomes a major factor. Designers use experiments and regression analysis to link friction with cage design features like bridge height and pocket depth. These studies help reduce friction and heat, which are critical for high-speed performance. Lubricant flow and cage design play a big role in keeping the bearing cool and stable.

Tip: When comparing precision bearing differences, remember that high precision ball bearings aim for the lowest possible error, while high speed ball bearings aim for the best performance at fast rotations.

Performance Impact

Design choices in ball bearings directly affect how they work in real machines. Several factors influence performance:

- Materials such as SAE 52100 chrome steel or DD400 stainless steel change the noise level, hardness, and resistance to corrosion.

- Lubrication type, including greases and oils, affects temperature rating, noise, load capacity, and running torque.

- Cage type, such as metal ribbon retainers or plastic crowns, impacts torque and makes some bearings better for high-speed use.

- Noise level depends on the roundness and surface finish of the raceway. Specialized meters measure this to ensure quality.

- Precision and tolerances, set by ABEC standards, affect fit, cost, and overall performance.

- Radial and axial play determine how loose the parts are inside the bearing. This influences fit and how the bearing works under different conditions.

- Internal geometry, including radial play, axial play, contact angle, and raceway curvature, changes how the load spreads across the bearing and how much stress builds up.

- Design parameters like race thickness and ball diameter affect how much load the bearing can handle and how stress is distributed.

- Dynamic models show that external loads can change cage stability and the way the bearing moves.

High precision ball bearings offer better accuracy and less vibration. These bearings work best in machines that need exact movement and low noise. High speed ball bearings perform better in machines that run fast for long periods. They resist heat and friction, which helps them last longer at high speeds. Both types use special designs to match their main goal—either precision or speed.

Comparison Table: Tolerance, Speed performance,

Choosing between high precision and high speed ball bearings depends on what the machine needs most. Some machines need very accurate movement. Others need to spin very fast. The table below shows how these two types of ball bearings compare in important areas.

| Feature | High Precision Ball Bearings | High Speed Ball Bearings |

|---|---|---|

| Accuracy | Very high; tight tolerances for exact movement | Good; designed for stable rotation at high RPM |

| Speed Capability | Moderate; not made for extreme speeds | Excellent; built for high rotational speeds |

| Load Capacity | High; supports both radial and axial loads | Moderate; optimized for speed over heavy loads |

| Durability | Long life in clean, controlled environments | Long life at high speeds with proper lubrication |

| Cost | Higher; advanced materials and design | Moderate to high; depends on materials used |

Note: Ball bearings with high precision work best in machines that need exact control, like medical devices or robotics. Ball bearings for high speed fit best in motors, turbines, or fans that spin quickly.

Ball bearings play a key role in many machines. High precision ball bearings help reduce vibration and noise. High speed ball bearings keep machines running smoothly at fast speeds. Both types use special materials and designs. Each type offers unique benefits. Engineers look at accuracy, speed, load capacity, and cost before choosing the right ball bearings. The right choice helps machines last longer and work better.

Selection Guide

Application Needs

Selecting the right ball bearings starts with understanding the specific needs of the application. Some machines require exact movement and low noise. Others need to run at very high speeds for long periods. High precision ball bearings work best in equipment that demands tight tolerances and minimal vibration, such as medical devices or robotics. In contrast, high-speed applications like turbines, compressors, and motors benefit from bearings designed for stability at fast rotations.

A quick checklist for matching application needs:

- Does the machine require extremely accurate positioning?

- Will the equipment operate at very high speeds?

- Is low noise or minimal vibration a priority?

- Does the application involve frequent starts and stops?

Choosing the right type ensures the machine performs as expected and lasts longer.

Load & Speed

Load and speed are critical factors in bearing selection. Different types of ball bearings handle loads and speeds in unique ways. Angular contact ball bearings are ideal for high-speed applications and can support both radial and axial loads. Single row angular contact bearings suit pumps and compressors, while double row versions fit machine tool spindles and automotive hubs. Four point contact ball bearings manage axial loads in both directions and save space. Radial ball bearings mainly support radial loads and work well in electric motors and gearboxes. Self-aligning ball bearings are best when misalignment may occur.

The table below summarizes key load and speed concepts:

| Parameter/Concept | Description/Formula/Value |

|---|---|

| Dynamic Capacity (C) | Load rating representing bearing’s ability to endure load (units: N or lbs) |

| Equivalent Bearing Load (P) | Calculated load combining radial and axial loads for life calculation |

| Speed (N) | Rotating speed in revolutions per minute (RPM) |

| L10 Life Formula | L10 = (C / P)^3 (in millions of revolutions) |

| L10 Life in Hours | L10 (hrs) = (16667 / N) * (C / P)^3 |

| Minimum Bearing Load (Pmin) | Pmin = 0.02 * C (minimum load to avoid skidding and smearing) |

| Misalignment Tolerance | Max misalignment ~0.0005 radians (0.03°) for rated life calculations |

When comparing options, engineers should match the bearing type to the expected load and speed. High precision ball bearings offer superior precision for controlled environments, while bearings for high-speed applications deliver reliable performance at elevated RPMs.

Environment

Environmental conditions play a major role in bearing selection. Factors such as temperature, moisture, dust, and vibration affect how ball bearings perform and how long they last. For example, high temperatures can reduce load capacity and change material properties. Low temperatures may increase lubricant viscosity and starting torque. Wet or humid conditions require corrosion-resistant materials and effective seals. Dusty environments need strong sealing to prevent contamination. External vibrations can cause fretting and extra stress, so some bearings are better suited for these situations.

| Environmental Factor | Impact on Bearing Selection and Performance |

|---|---|

| High Temperature | May require special materials and reduced load capacity above 100°C |

| Low Temperature | Needs lubricants that stay fluid and bearings that start easily |

| Vacuum | Demands special lubricants or bearing types |

| Wet and Humid Conditions | Corrosion resistance and sealing become critical |

| Dirt and Dust | Strong seals protect against contamination |

| External Vibration | Some bearings handle vibration better than others |

Considering these factors helps optimize bearing performance, reduce costs, and improve reliability.

Expert Help

Consulting an expert or trusted supplier can make a big difference in choosing the right ball bearings. Suppliers who follow recognized standards, such as ISO 9001, provide reliable products. Companies with a wide range of bearings and a strong reputation offer more options and better support. Access to technical experts helps answer questions about precision, load, speed, and environmental challenges. Good customer support ensures the right fit for each application. Competitive pricing and product availability also matter.

Tip: When facing complex requirements or unique environments, always seek advice from experienced suppliers or engineers. Their knowledge can help avoid costly mistakes and ensure the best performance. TFL’s professional team is always available and willing to assist you with your inquiries.

Quick-Reference Checklist

Identify the main application need: precision or speed?

Determine the expected load and speed.

Assess environmental factors: temperature, moisture, dust, vibration.

Check for special requirements: misalignment tolerance, space limits.

Consult a reputable supplier or expert for complex cases.

Choosing between high precision ball bearings and those for high-speed applications depends on careful comparison of these factors. The right decision leads to better machine performance and longer service life.

Choosing between high precision and high speed ball bearings depends on the needs of each application. The table below highlights key differences:

| Attribute | High Precision / High Speed Ball Bearings | Roller Bearings |

|---|---|---|

| Load Capacity | Lower (5 kN load, L10 ≈ 34,000 hrs) | Higher (5 kN load, L10 ≈ 71,000 hrs) |

| Speed Range | Up to 400,000 RPM in some tools | Lower, best for heavy-duty use |

| Friction | Lower, smooth and quiet | Slightly higher |

| Compactness | More compact | Bulkier |

Ball bearings offer excellent speed and low friction for motors, turbines, and medical devices. Users should review the selection guide to match the right ball bearings to their machines. For expert advice and the best solutions, TFL can help.

FAQ

What is the main difference between high precision and high speed ball bearings?

High precision ball bearings focus on accuracy and tight tolerances. High speed ball bearings focus on stable performance at fast rotations. Each type suits different machine needs.

Which applications need high precision ball bearings instead of high speed ones?

High precision ball bearings work best in robotics, medical devices, and measuring instruments. These machines need exact movement and low vibration. High speed ball bearings fit motors, turbines, and fans that run at high RPM.

How do materials differ between high precision and high speed ball bearings?

| Bearing Type | Common Materials |

|---|---|

| High Precision | Chrome steel, advanced coatings |

| High Speed | Hybrid ceramic, stainless steel |

Material choice affects durability, speed, and resistance to wear.

Can one bearing type replace the other in most machines?

Engineers should not swap high precision and high speed ball bearings without careful review. Each type has unique strengths. Using the wrong type may reduce machine life or performance.