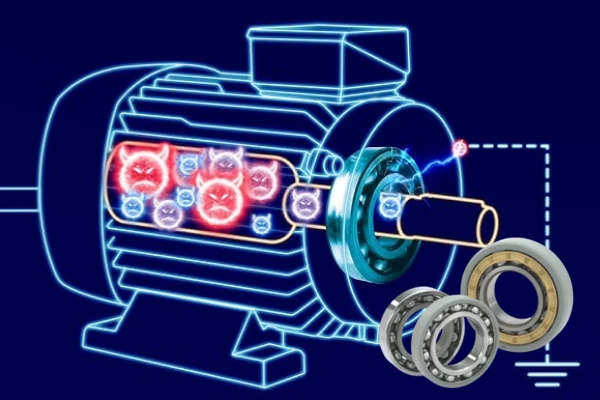

Electrically insulated bearings help protect electric motors from damage. VFD-driven motors have a bigger risk of shaft current. This current can move through the shaft and harm the bearing. It can cause corrosion inside the bearing. Without good insulation, bearings can fail early. This can lead to expensive downtime. Many people do not know how easily shaft current can hurt a motor. Insulated bearings stop electricity from moving through the shaft. They keep the current out of the bearing. You need strong insulation to stop corrosion. This helps your motor last longer. More industries use insulated bearings as VFDs become more common. Insulation is an easy way to fix shaft current problems.

Key Takeaways

- Shaft currents in motors with VFDs can hurt bearings. This damage can look like small holes or rust. It can make motors break early and stop working, which costs a lot to fix.

- Electrically insulated bearings have ceramic coatings. These coatings stop bad currents from getting in. This keeps the bearings safe and helps motors last longer.

- Insulated ball bearings block electricity very well. They also make less noise and less rubbing. This helps motors work longer and need fewer repairs.

- Picking the best insulated bearing depends on many things. You need to think about how heavy the load is, how fast it spins, where it is used, and how strong the insulation is. This helps the motor work well.

- You must install insulated bearings and grounding rings the right way. You also need to check and care for them often. This gives the best protection and saves money on repairs.

Bearing Current Damage

Causes in Modern Motors

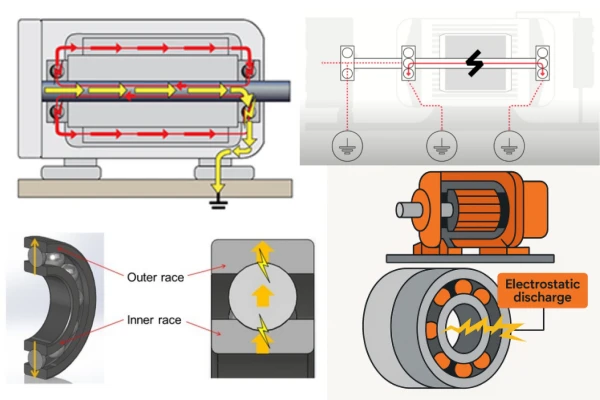

You might wonder why shaft current is a big problem now. Many modern electric motors use variable frequency drives (VFDs) to change speed. VFDs work by sending fast switching pulses. These pulses make high-frequency voltages. The voltages build up on the shaft and create shaft voltage. This voltage finds a way through the bearings. That makes shaft current flow.

Stray electrical currents move through the shaft and bearings. This happens more when grounding is not good. The common-mode voltage from VFDs makes shaft current more likely. This can cause galvanic corrosion and electric corrosion inside the bearing. Over time, shaft voltage and current cause current erosion. They also damage the bearing surfaces. Shaft current can cause serious problems in any motor that uses a VFD.

Tip: If your motor makes strange noises or shakes, it might have shaft current damage.

Failure Modes

Shaft current can harm the inside of the bearing in many ways. The most common problems are pitting, fluting, and micro-cratering. Pitting happens when shaft voltage goes through the lubricant. This makes tiny holes on the bearing surface. Fluting looks like ridges on the raceways. Micro-cratering gives the surface a rough, dull look. These types of current erosion and galvanic corrosion make the bearing weaker. Electric corrosion also ruins the lubricant. This causes black grease and more friction. When the lubricant stops working, metal parts touch each other. This leads to even more current erosion and galvanic corrosion. These problems often start with loud noise or shaking. They can quickly cause the bearing to fail because of current.

Impact on Reliability

Bearing current damage can really hurt electric motor reliability. When shaft current causes corrosion and current erosion, the bearing wears out faster. Lubricant breakdown makes more friction and heat. This lowers how well the motor works. If you do not find these problems soon, the motor might fail suddenly. This means more downtime and higher repair bills. Sometimes, too much grease and shaft current damage can even ruin the winding. You need to look for signs of galvanic corrosion and electric corrosion. This helps your motor run well. Stopping shaft voltage and current erosion saves money. It also keeps your equipment working well.

Electrically Insulated Bearings

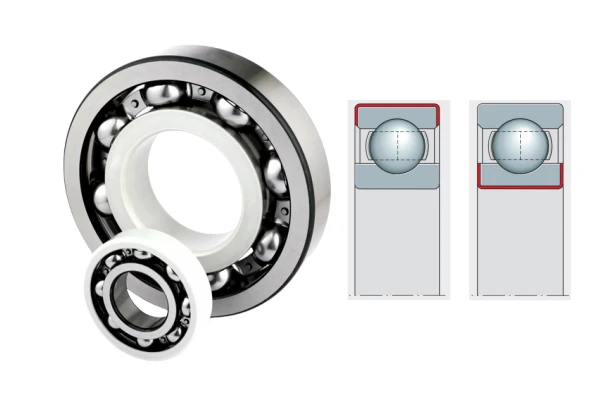

Insulation Methods

You need strong insulation to keep your motor safe from shaft current damage. Electrically insulated bearings use special insulated bearing technology to stop electrical currents from going through the bearing. The most common way to insulate is by using a ceramic coating, usually made from aluminum oxide. This coating goes on the inner or outer ring of the bearing. It acts like a wall and stops electricity from passing through. The coating can be thin or thick, from 50 to 500 microns. Thicker coatings give better voltage resistance and protect the bearing more.

You can look at the table below to see how different insulation technologies compare:

| Insulation Technology | Material | Application Method | Coating Thickness | Dielectric Strength (Breakdown Voltage) | Notes |

|---|---|---|---|---|---|

| INSOCOAT Bearings | Aluminum Oxide (Al2O3) | Plasma Spraying | ~50 µm | Up to 1,000 V | Used in traction motors and electric machinery |

| NKE Bearings | Oxide Ceramic (Al2O3) | Plasma Spraying | Thin film | At least 2,000 V | Sealed to prevent moisture, resistance > 50 MΩ |

| TFL Bearings | Oxide Ceramic | Coating | 50-200 µm | Above 1,000 V | Used in EV motors, wind turbines, spindles, railroads |

| SDTFL Bearings | Aluminum Oxide (Al2O3) | Special Coating | 100-500 µm | Up to 3,000 V | High resistance (50-200 MΩ), protects from sparking damage |

Electrically insulated bearings with ceramic coatings can handle voltages up to 3,000 V. This strong insulation keeps harmful currents out of your motor bearings. The insulation layer also fights off moisture and corrosion, so it lasts longer even in tough places.

Some bearings use ceramic rolling elements instead of a coating. These hybrid ceramic bearings have silicon nitride balls that block current. They give some electrical insulation, but ceramic-coated bearings protect better against shaft current. Hybrid bearings are good for high-speed motors, but they do not block shaft current as well as insulated ball bearings with ceramic coatings.

Note: Insulated bearings use a special coating to stop shaft current. This keeps your motor safe from electrical damage.

Insulated Ball Bearings

Insulated ball bearings are very important for protecting your motor. These bearings have a ceramic insulation layer, usually on the outside ring. The layer gives the bearing a resistance value over 50 megaohms. This high resistance stops most electrical current from getting through the bearing. When you use insulated ball bearings, you lower the chance of pitting, fluting, and grease problems.

Insulated ball bearings like the 6310M/C3VL0241 have a thick aluminum oxide coating. This coating can handle up to 3,000 V and keeps the resistance high, between 50 and 200 megaohms. You get strong electrical insulation and long-lasting protection for your motor. Insulated deep groove ball bearings are used in VFD-driven motors, wind turbines, and electric vehicles. They help you avoid expensive repairs and downtime.

| Feature | Insulated Ball Bearings (Ceramic Coating) | Hybrid Ceramic Bearings (Ceramic Balls) |

|---|---|---|

| Insulation Method | Ceramic coating on ring | Silicon nitride balls |

| Electrical Insulation Level | High (up to 3,000 V) | Moderate |

| Resistance Value | >50 MΩ | Lower |

| Preferred Application | High-power, VFD motors | High-speed, low shaft voltage motors |

| Mechanical Properties | Maintains rigidity | Lightweight, low friction |

Motor Insulated Bearings

Motor insulated bearings give the best protection against shaft current. These bearings use a ceramic coating to block electrical paths through the bearing. You can use them in any motor where VFDs or high voltages are used. Motor insulated bearings keep shaft current from hurting the bearing surfaces and the lubricant. This means your motor lasts longer and needs less fixing.

You should pick motor insulated bearings if you want to stop electrical corrosion, pitting, and fluting. These bearings work better than regular bearings in VFD-driven motors. They stop voltage from going through the bearing, which keeps your motor working well and makes it last longer. You can use motor insulated bearings alone or with shaft grounding rings for extra safety.

When you compare motor insulated bearings to other ways of protection, you see clear benefits. Shaft grounding rings and carbon brushes can also help, but they need more care and do not last as long. Insulated bearings cost more than regular bearings, but they give you better electrical protection and lower the risk of failure.

| Protection Method | Relative Cost Compared to Standard Components | Key Notes |

|---|---|---|

| Insulated Bearings | 3-5 times mo re expensive | Protects motor bearings; high insulation; long life |

| Hybrid/Ceramic Bearings | 7-10 times more expensive | Electrically inert; high speed; very high cost |

| Shaft Grounding Rings | More economical | Protects both motor and driven equipment; low maintenance |

You get the most value from motor insulated bearings when you need your motor to be very reliable and last a long time. They block shaft current, protect your motor, and lower the chance of sudden failure. You also save money on repairs and downtime. If you want the best electrical insulation and protection for your motor, choose motor insulated bearings.

Benefits for Electric Motor Reliability

Longer Service Life

You want your electric motor to last a long time. Insulated bearings help you reach this goal. They block bad shaft currents that can hurt the bearing. This keeps the bearing surface safe from damage. Using insulated bearings stops electric arc damage, pitting, and fluting. This means your bearings do not wear out fast.

- Hybrid ceramic bearings can help your motor last up to 10 times longer than motors with regular steel bearings.

- The insulation blocks shaft currents, so you see less wear and fewer electric arcs.

- These bearings also cut down friction and let your motor run faster.

- You get longer bearing life and better motor performance.

- Without insulation, bearings get hot, noisy, and the grease breaks down, which makes them wear out sooner.

Insulated bearings help your machines work longer and better. You spend less time fixing motors and more time working.

Reduced Maintenance

Insulated bearings help your motor run well. They stop stray currents from hurting the inside of the bearing. This means you do not have to stop your machine for repairs as much. When you use insulated bearings, you can wait longer between maintenance checks.

Motors with insulated bearings run longer without trouble. You avoid sudden breakdowns and do not need emergency repairs as often. This makes your job easier and helps you plan when to do maintenance. You also save time because you do not have to change bearings as much.

Lower Costs

You want to spend less money on your electric motors. Insulated bearings help by lowering repair and downtime costs. When you protect your bearings from electrical damage, you avoid expensive rebuilds and lost work time.

Here is a table that shows how insulated bearings can save you money:

| Cost Component | Standard VFD Motor | VFD Motor with Insulated Bearings |

|---|---|---|

| Downtime Costs | High | Much lower |

| Rebuild Costs | High | Greatly reduced |

| Maintenance Costs | Frequent | Less frequent |

| Total Cost (5 years) | Higher | Lower |

Insulated bearings help you worry less. Your motor will last longer, need less fixing, and cost less to use. This is why insulated bearings are very important for electric motor reliability.

Applications and Selection

Where Insulation Is Essential

Motor insulated bearings are needed in many strong machines. These bearings keep your equipment safe from electrical harm. Insulation is most important where electric currents can damage bearings. VFD-driven motors, high-voltage systems, and wind turbines have high risks. Electric vehicles also need insulated ball bearings. Inverter-driven motors in these cars make stray voltages on the shaft. Without insulation, regular bearings in these motors can break early.

You also find motor insulated bearings in:

- Power plants, like thermal generators and hydrogenerators

- Railway traction motors and wheelsets

- Mining machines such as loaders and crushers

- Petrochemical compressors and high-voltage motors

- Mechanical industries, like cranes, presses, and textile machines

Insulation stops shaft current and keeps bearings safe. That is why insulated ball bearings are used in these tough jobs.

Choosing Insulated Bearings

You want to choose the best motor insulated bearings for your job. First, check the insulation strength. The coating should handle up to 1000 V DC and stick well. Next, think about how much weight the bearing will hold. Use ball bearings for light loads and roller bearings for heavy or shock loads. Think about which way the load pushes and how fast your motor spins. High-speed motors work best with insulated ball bearings.

You should also pick the right size and accuracy for your machine. Look at the environment. If it is humid or hot, use bearings with coatings that fight moisture and heat. In places with rust, pick bearings with extra anti-rust features. Cost is important too. Motor insulated bearings cost more, but they save money by stopping galvanic erosion and lowering repairs.

| Selection Criteria | What to Check For |

|---|---|

| Insulation Properties | Strong, even coating; handles up to 1000 V DC |

| Load and Speed | Ball for light or fast; roller for heavy loads |

| Environment | Fights moisture, heat, and rust |

| Size and Accuracy | Fits your machine; meets your needs |

| Cost and Savings | Costs more at first, but saves on repairs |

Installation and Maintenance

You need to install and care for motor insulated bearings the right way. For motors up to 100 hp, use a shaft grounding ring with the insulated bearing. For bigger motors, put insulated bearings on one end and a grounding ring on the other. Always clean the shaft before putting on the grounding ring. Make sure the ring sits flat and touches well. Do not put the ring over keyways unless you fill them with epoxy.

After you put on the grounding ring, test the resistance. It should be less than 2 ohms. Use conductive epoxy or screws to mount it. In dirty or wet places, cover the ring with seals. Check the grounding ring and insulation often for wear or damage. Good care helps your motor insulated bearings last longer and keeps your motor safe from shaft current.

Tip: Always follow the maker’s instructions when you install and care for insulated ball bearings. This gives your high-performance machines the best protection.

You need motor insulated bearings to keep your machines safe from electrical damage and rust. If you do not use them, you might have:

- Damage from electrical discharge machining and pitting on bearing surfaces

- More friction, louder sounds, and bearings that break too soon

- Extra repair bills and machines stopping when you do not expect it

Motor insulated bearings stop bad currents, help your machines last longer, and let them work without problems. You get more trust in your machines and spend less money as time goes on. If you want to stop expensive fixes and keep your workplace safe, pick motor insulated bearings.

Reach out to TFL Bearings for help and top-quality motor insulated bearings that match what you need.

FAQ

Why do you need electrically insulated bearings in VFD motors?

VFD motors make high-frequency voltages. These voltages can cause shaft currents. Shaft currents hurt bearings very fast. Insulated bearings block these currents. This keeps your motor safe and saves money on repairs.

Why do regular bearings fail in electric motors?

Regular bearings let shaft currents go through them. These currents cause pitting, fluting, and grease to break down. You will notice more noise and heat. Insulated bearings stop this kind of damage. They help your motor last much longer.

Why should you choose insulated bearings over shaft grounding rings?

Insulated bearings protect your motor by themselves. You do not need extra parts or lots of checks. Shaft grounding rings need more care and can wear out faster. Insulated bearings are a simple and strong way to stop shaft current damage.

Why does insulation thickness matter in bearings?

Thicker insulation gives better voltage resistance. It blocks higher shaft voltages. This keeps your bearings safe during hard work. Always look at insulation thickness when picking a bearing.

Why do electric vehicles and wind turbines use insulated bearings?

Electric vehicles and wind turbines use VFDs and high voltages. These make strong shaft currents. Insulated bearings stop these currents from hurting the motor. Your motor lasts longer and breaks down less often.