Bearing lubrication oil plays a vital role in the performance, reliability, and service life of rotating machinery. Bearings operate under constant friction, load, and speed, and without proper lubrication, even the most precisely manufactured bearings can fail prematurely. Understanding how bearing lubrication oil works, how it differs from grease, and how to select the right lubricant is essential for engineers, maintenance professionals, and equipment operators across industrial sectors.

What Is Bearing Lubrication Oil

Bearing lubrication oil is a fluid lubricant specifically formulated to reduce friction, minimize wear, and dissipate heat in bearing assemblies. Unlike grease, which consists of oil thickened with additives, lubrication oil flows freely within the bearing and surrounding components. This flow allows oil to continuously replenish the contact surfaces between rolling elements and raceways.

Oil lubrication is commonly used in applications involving high speeds, elevated temperatures, or systems where heat removal is critical. It also allows contaminants to be flushed away from bearing contact zones, improving cleanliness and performance.

Why Bearings Require Lubrication

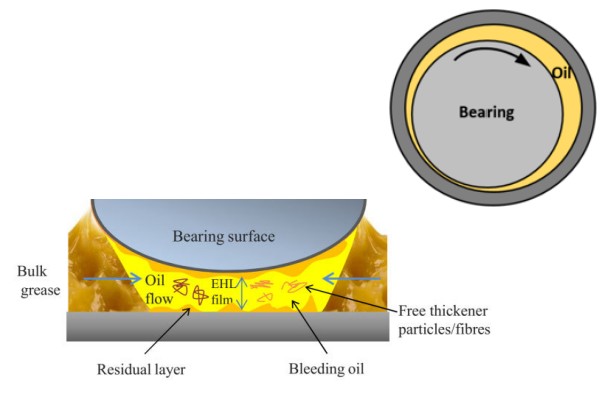

Bearings rely on lubrication to form a protective film between rolling elements and raceways. This film prevents direct metal-to-metal contact, reducing friction and wear. Proper lubrication also helps control operating temperature by carrying heat away from friction zones.

Without adequate lubrication, bearings experience increased friction, surface fatigue, and accelerated wear. Over time, this leads to noise, vibration, overheating, and eventual failure. Lubrication is therefore not optional but a fundamental requirement for bearing operation.

Oil Lubrication vs Grease Lubrication

Both oil and grease are widely used for bearing lubrication, but each serves different application needs. Oil lubrication offers superior heat dissipation and is better suited for high-speed or high-temperature environments. Its ability to flow allows continuous lubrication and cooling.

Grease lubrication, on the other hand, is often preferred for sealed or low-speed applications where simplicity and reduced maintenance are priorities. Grease stays in place and requires less frequent relubrication but provides limited cooling compared to oil.

Choosing between oil and grease depends on operating conditions, bearing type, speed, temperature, and maintenance strategy.

How Bearing Lubrication Oil Works

Bearing lubrication oil works by creating a thin film that separates contact surfaces during operation. In rolling bearings, this film forms between the rolling elements and raceways. The thickness of the oil film depends on viscosity, speed, load, and temperature.

At adequate film thickness, bearings operate in a full-film or elastohydrodynamic lubrication regime, where surface contact is minimal. This significantly reduces wear and extends bearing life. Insufficient oil film thickness leads to boundary lubrication, increasing the risk of surface damage.

Viscosity and Its Importance

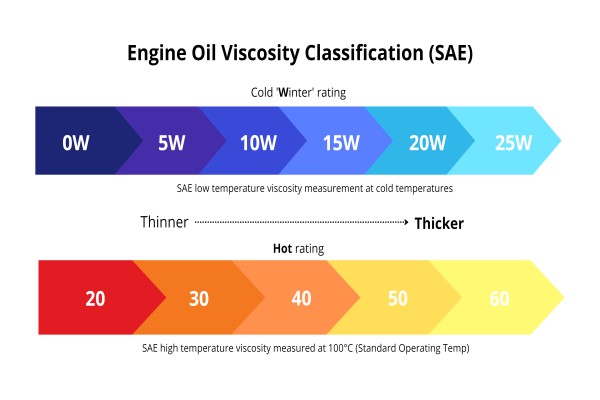

Viscosity is one of the most important properties of bearing lubrication oil. It determines the oil’s ability to maintain a stable lubrication film under load. Oils with low viscosity flow easily but may fail to maintain adequate film thickness under heavy loads. High-viscosity oils provide better load support but may increase friction and operating temperature.

Selecting the correct viscosity involves balancing load-carrying capacity with speed and temperature. Manufacturers typically provide viscosity recommendations based on bearing size and operating conditions.

Temperature Effects on Lubrication Oil

Temperature has a direct impact on oil viscosity and lubrication performance. As temperature increases, oil viscosity decreases, reducing film thickness. Excessive heat can cause oil oxidation, leading to sludge formation and reduced lubrication effectiveness.

Bearing lubrication systems must therefore be designed to control temperature through proper oil selection, circulation, and cooling. Oil with suitable thermal stability ensures consistent lubrication across the operating temperature range.

Common Types of Bearing Lubrication Oils

Mineral oils are widely used for general-purpose bearing lubrication due to their cost-effectiveness and availability. Synthetic oils offer superior performance in extreme conditions, providing better thermal stability, oxidation resistance, and low-temperature performance.

Additives are often included to enhance oil performance. These may include anti-wear agents, corrosion inhibitors, and oxidation stabilizers. The selection of oil type depends on application requirements and environmental conditions.

Lubrication Methods Using Oil

Bearing lubrication oil can be applied using various methods, depending on system design and operating conditions. Oil bath lubrication immerses part of the bearing in oil, allowing rotation to distribute lubricant. Oil circulation systems continuously supply and filter oil, providing effective cooling and contamination control.

Oil mist and oil-air lubrication methods deliver precise amounts of oil to high-speed bearings, minimizing friction and heat generation. These methods are commonly used in precision machinery and high-speed spindles.

Contamination Control and Oil Cleanliness

Contamination is a major cause of bearing failure, even in well-lubricated systems. Dirt, moisture, and metal particles can disrupt the lubrication film and cause abrasive wear. Bearing lubrication oil must therefore be kept clean through effective sealing and filtration.

Regular oil analysis helps detect contamination, oxidation, and additive depletion. Monitoring oil condition allows maintenance teams to take corrective action before bearing damage occurs.

Bearing Types and Oil Lubrication Suitability

Oil lubrication is particularly well suited for certain bearing types and applications. High-speed ball bearings, cylindrical roller bearings, and tapered roller bearings often benefit from oil lubrication due to heat generation and load conditions.

In contrast, some sealed bearings are designed primarily for grease lubrication and may not be compatible with oil systems. Understanding bearing design and manufacturer recommendations is essential when selecting lubrication methods.

Maintenance and Oil Change Intervals

Proper maintenance is essential to ensure effective bearing lubrication. Oil change intervals depend on operating conditions, temperature, contamination levels, and oil type. Synthetic oils generally offer longer service intervals than mineral oils.

Overextended oil use can lead to oxidation, viscosity breakdown, and additive depletion. Establishing a proactive maintenance schedule based on oil analysis helps maximize bearing life and system reliability.

Common Lubrication-Related Bearing Failures

Many bearing failures can be traced back to lubrication issues. These include insufficient lubrication, incorrect oil viscosity, contamination, and overheating. Symptoms often include increased noise, vibration, and elevated operating temperature.

Addressing lubrication problems early prevents secondary damage to shafts, housings, and surrounding components. Proper lubricant selection and maintenance practices are therefore critical for long-term performance.

Selecting the Right Bearing Lubrication Oil

Selecting the correct bearing lubrication oil requires careful evaluation of load, speed, temperature, and environmental conditions. Manufacturer guidelines and application data provide valuable insight into suitable oil types and viscosities.

Technical resources explaining lubricant selection for bearings, such as guidance shared by SDTFL Bearing, help engineers understand how lubrication choices influence bearing performance and service life.

Role of Lubrication in Bearing Efficiency

Effective lubrication not only protects bearings but also improves overall system efficiency. Reduced friction leads to lower energy consumption and smoother operation. In large industrial systems, optimized lubrication can result in significant energy savings over time.

Efficient lubrication also contributes to quieter operation and reduced vibration, improving working conditions and equipment accuracy.

Environmental and Sustainability Considerations

Modern industries increasingly focus on sustainability and environmental responsibility. Lubrication oil selection can support these goals through extended service intervals, reduced waste, and environmentally friendly formulations.

Biodegradable and low-toxicity oils are available for applications where environmental impact is a concern. Proper lubrication management reduces oil consumption and minimizes environmental risk.

Conclusion

Bearing lubrication oil is a critical element in ensuring reliable, efficient, and long-lasting bearing performance. By forming a protective film, controlling heat, and reducing friction, oil lubrication supports bearings in demanding operating conditions where grease may be insufficient.

Understanding oil properties, lubrication methods, and maintenance requirements enables engineers and maintenance professionals to select the right bearing lubrication oil for their applications. With proper lubrication practices, bearings can achieve optimal performance, reduced downtime, and extended service life, supporting reliable operation across a wide range of industrial systems.

Protect Your Machinery with Premium Bearings

Proper bearing lubrication oil is essential, but it can only protect a bearing that is built to last. At SDTFL Bearings, we manufacture high-precision bearings designed to work in harmony with advanced lubrication systems, ensuring maximum efficiency and minimal downtime.

Don’t let friction slow you down. Whether you need advice on the best lubrication methods for our products or need to source durable replacements, we are ready to assist.

Get expert support today:

- Email: info@sdtflbearing.com

- Phone: +86 158 0663 1151