How Insulated Bearings Safeguard Wind Turbines from Electrical Damage

Wind turbine insulated bearings prevent electrical erosion, reducing downtime and maintenance costs while extending turbine lifespan and reliability.

Wind turbine insulated bearings prevent electrical erosion, reducing downtime and maintenance costs while extending turbine lifespan and reliability.

Compare ceramic bearings and coated insulated bearings for performance, cost, and durability. See which coated insulated bearings fit your application best.

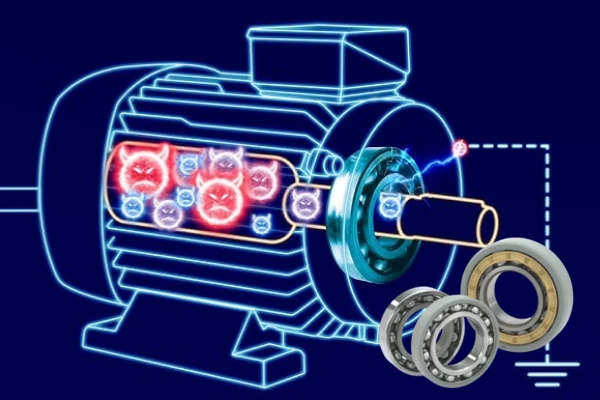

Insulated bearings in VFD motors prevent electrical damage, boost reliability, and cut maintenance costs by reducing bearing failures and downtime.

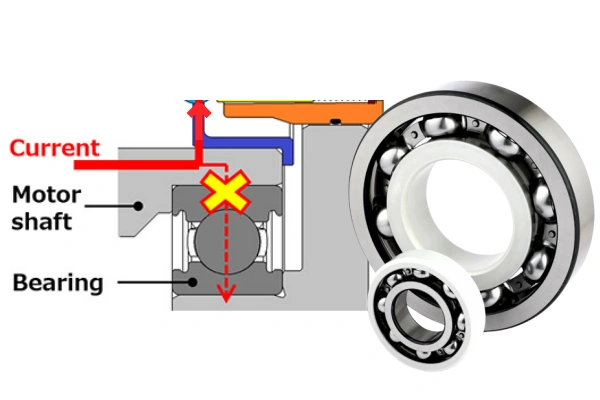

Electrically Insulated Bearings prevent bearing current corrosion in electric motors, ensuring longer service life and reducing costly downtime.

Coated insulated bearings feature a ceramic layer that blocks electrical currents, preventing bearing damage and extending machinery service life.

High-temperature failure in machinery bearings can halt harvests. See how a Brazilian farmer solved this issue and learn prevention strategies for your farm.

During the busy farming season, every second counts. TFL agricultural bearings, with their high sealing performance, durability and maintenance-free design, help agricultural machinery operate efficiently, reduce downtime and ensure the farming schedule. They are widely trusted by users all over the world.

Learn to identify bad ball bearing sounds (grinding, squeaking), diagnose lubrication or wear issues, and get step-by-step solutions to fix or replace them.